Leading Manufacturers of Electronic Tensile Strength Testers for Quality Assurance in Materials Testing

Understanding the Importance of Electronic Tensile Strength Testers in Quality Control

In today’s manufacturing landscape, the demand for high-quality materials is more critical than ever. Whether it involves textiles, metals, plastics, or composites, the mechanical properties of materials significantly influence product performance and reliability. One of the key metrics used to assess a material's strength is its tensile strength, which measures the resistance of a material to deformation or rupture under tension. To obtain accurate measurements of tensile strength, manufacturers turn to electronic tensile strength testers.

Electronic tensile strength testers have revolutionized the way industries perform material testing. Unlike traditional mechanical testers, which could be cumbersome and less precise, electronic testers use advanced technology to provide highly accurate and reproducible results. They employ load cells and sensors that convert mechanical energy into an electronic signal, allowing for precise measurements of force and elongation during tensile tests.

The primary function of an electronic tensile strength tester is to determine the tensile strength of materials by applying a controlled tensile load until failure occurs. The data gathered during tests is invaluable; it not only provides crucial insights into material properties but also ensures that products meet industry standards and specifications, which are vital for safety and regulatory compliance.

One major advantage of electronic tensile strength testers is their ability to integrate with computer systems for real-time data acquisition and analysis. Users can visualize the stress-strain curves immediately after the test, allowing for faster interpretation of results. This connectivity enhances the testing process by enabling automated testing sequences, thereby reducing human error and increasing efficiency.

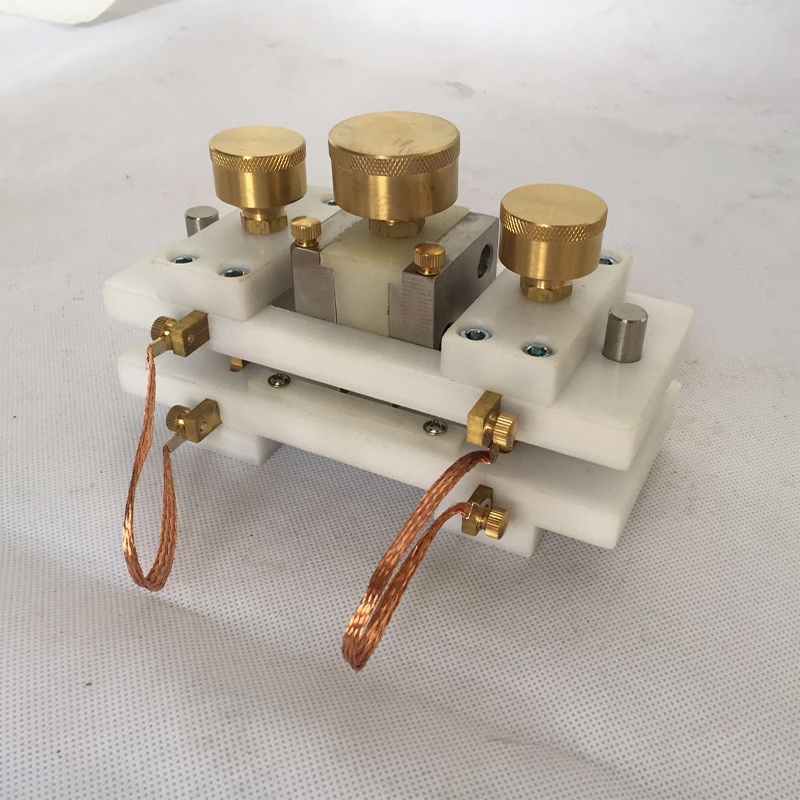

electronic tensile strength tester company

Moreover, electronic tensile strength testers feature sophisticated software that allows for extensive analysis and reporting. Users can customize test parameters, such as loading speed, and approach to failure, and create detailed reports that include histograms, graphs, and comparison charts. This functionality is particularly beneficial for research and development purposes, where precise data can lead to innovations in material formulation and application.

Industries such as aerospace, automotive, and construction rely heavily on electronic tensile strength testers to ensure their materials can withstand the demands of their operating environments. For instance, in the aerospace industry, components must endure extreme conditions, and even minor defects can lead to catastrophic failures. The use of tensile strength testing helps manufacturers select the right materials and maintain stringent quality controls throughout the production process.

Furthermore, as sustainability becomes a focal point for many companies, electronic tensile strength testers are increasingly being employed to test recycled materials and alternatives to traditional substances. This testing helps determine the viability of new materials and processes aimed at reducing environmental impact, ensuring that companies not only comply with regulatory standards but also meet consumer demand for greener products.

In conclusion, electronic tensile strength testers are essential tools in the arsenal of material testing technology. They provide accurate, reliable, and efficient means of assessing the mechanical properties of various materials, ensuring that manufacturers produce high-quality products that can withstand the rigors of their intended applications. With the growing emphasis on innovation and sustainability, the role of electronic tensile strength testers will only continue to expand, solidifying their place as a cornerstone in quality control and materials science. Industries that prioritize the adoption of such advanced testing methods will not only enhance their product quality but also gain a competitive edge in today’s dynamic market.

-

The Role of Tensile Force Testers in Quality Control and Material Science

NewsAug.01,2025

-

Maintenance and Safety Tips for Aging Ovens

NewsAug.01,2025

-

Density Balance in Forensic Science

NewsAug.01,2025

-

Advanced Optical Measurement Technologies

NewsAug.01,2025

-

A Buyer’s Guide to Tensile Test Machines

NewsAug.01,2025

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy