Leading Manufacturers of Universal Tensile Testing Machines for Accurate Material Strength Assessment

The Rise of Universal Tensile Tester Machine Factories

In the modern era of materials testing, universal tensile testers have emerged as vital components in ensuring quality and performance across various industries. These machines are designed to evaluate the tensile strength, compression, and overall mechanical properties of materials. To meet the increasing demand for accurate and reliable testing equipment, universal tensile tester machine factories have sprung up globally, marking a significant shift in manufacturing and quality control processes.

The Importance of Universal Tensile Testing

Universal tensile testers are essential for determining how materials respond to external forces. Whether in the aerospace, automotive, construction, or even textiles industries, understanding the tensile strength and ductility of materials can be the difference between success and failure. These machines allow manufacturers to simulate real-world conditions, providing critical data that can help in material selection, quality assurance, and compliance with regulatory standards.

The Manufacturing Process

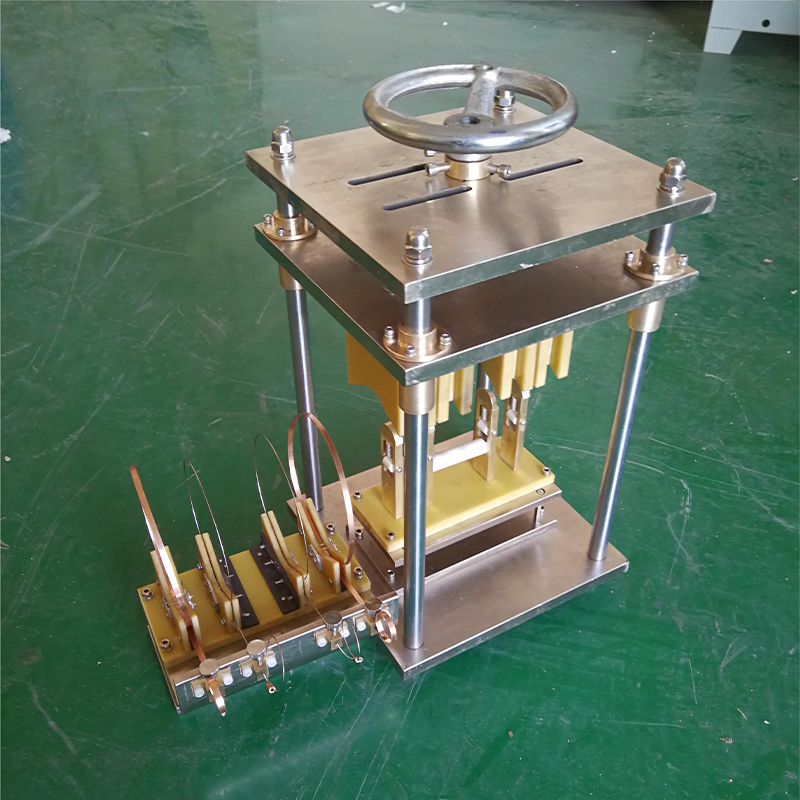

The manufacturing of universal tensile testers involves complex engineering and design processes. Factories typically employ skilled engineers and technicians who specialize in the fields of mechanical engineering and materials science. The production begins with the design phase, where the specifications of the tester are outlined, including load capacity, measurement accuracy, and software integration.

Once the design is approved, manufacturing follows a meticulous process. High-quality materials, such as steel and aluminum, are sourced to ensure durability and precision. Advanced CNC (Computer Numerical Control) machines are commonly used to create components with extreme accuracy. Each part is meticulously fabricated, tested, and assembled. Quality control is paramount, with each machine undergoing rigorous testing to confirm that it meets the specified standards before leaving the factory.

Technological Advancements

universal tensile tester machine factories

Recent years have seen significant technological advancements in universal tensile testers. Factories are investing in automation and state-of-the-art technologies to enhance production efficiency and testing accuracy. The integration of artificial intelligence (AI) and machine learning has enabled manufacturers to optimize testing processes, predict material behavior under various conditions, and automate data collection and analysis.

Moreover, the emergence of software solutions that allow for real-time monitoring and data analytics has transformed how companies interpret and utilize testing results. This ability not only streamlines the testing process but also fosters a culture of innovation as businesses can adapt quickly based on data-driven insights.

Sustainability in Manufacturing

As industrial practices evolve, sustainability has become a critical concern for universal tensile tester machine factories. Many manufacturers are now adopting eco-friendly practices, from using sustainable materials to implementing energy-efficient processes. This shift towards sustainability is not only beneficial for the environment but also appeals to a growing segment of consumers who prioritize corporate responsibility in their purchasing decisions.

The Future of Universal Tensile Tester Factories

Looking ahead, the future of universal tensile tester factories seems promising. With the continual evolution of materials science, particularly in sectors such as nanotechnology and biomaterials, the demand for sophisticated testing equipment is only expected to rise. Factories that emphasize innovation, quality, and sustainability will likely lead the charge in meeting these needs.

In conclusion, universal tensile tester machine factories play a crucial role in the manufacturing and quality assurance landscape. Through innovative design, advanced technology, and a commitment to sustainability, these factories are not only meeting current industry demands but are also shaping the future of material testing. As industries increasingly rely on precise and reliable data to inform decision-making, the impact of these factories will undoubtedly resonate across various sectors.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy