low resistance tester

Understanding Low Resistance Testers Essential Tools for Electrical Applications

Low resistance testers are indispensable instruments used in various electrical applications to measure the resistance of conductive materials with high accuracy. Unlike standard ohmmeters, which typically measure resistance in the range of megohms, low resistance testers focus on measurements in milliohms, making them crucial for ensuring the reliability and efficiency of electrical systems.

The principle behind a low resistance tester involves passing a constant current through the material whose resistance is being measured and then calculating the voltage drop across it. Ohm's Law (V = I × R) underpins this process, enabling the device to determine resistance based on the measured voltage (V) and the known current (I). This precise measurement capability is particularly relevant in testing electrical connections, cables, and components where low resistance is essential for optimal performance.

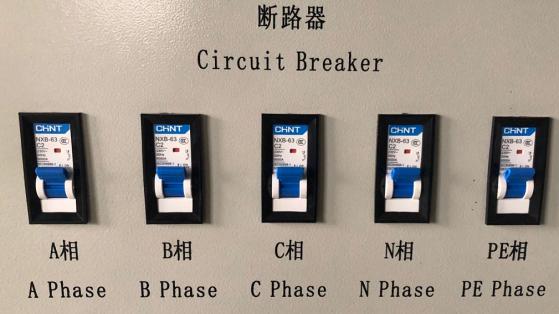

One of the primary applications of low resistance testers is in the testing of electrical connections, such as circuit breakers, busbars, and relay contacts. Poor connections can lead to overheating, increased power loss, and eventual system failure. By measuring the resistance at these junctions, technicians can identify and rectify potential issues before they escalate into significant problems. Regular testing helps ensure that electrical systems operate efficiently, minimizing downtime and maintenance costs.

low resistance tester

In addition to connections, low resistance testers are instrumental in evaluating the integrity of conductors, especially in large power distribution networks and industrial plants. Over time, factors such as corrosion, mechanical stress, and environmental conditions can increase resistance within conductors, affecting their performance. Utilizing a low resistance tester allows operators to monitor these changes proactively, ensuring that preventive maintenance can be performed when necessary.

The accuracy of low resistance measurements typically hinges on several factors, including the tester design, measurement method, and environmental conditions. Modern low resistance testers incorporate advanced features such as multiple test currents, automatic temperature compensation, and data logging capabilities. These enhancements ensure that users obtain reliable readings even in challenging conditions.

Safety is another critical consideration when using low resistance testers. The high currents used during testing can pose hazards, hence proper adherence to safety protocols and manufacturer guidelines is essential. Users should wear appropriate personal protective equipment (PPE) and make sure that the area is free from hazards when conducting tests.

In conclusion, low resistance testers play a vital role in maintaining the reliability of electrical systems across various sectors. Their ability to deliver precise measurements helps prevent costly equipment failures and enhances operational efficiency. As technology advances, these testers continue to evolve, offering enhanced functionalities that support the ever-growing demands of the electrical industry. For anyone involved in electrical maintenance or quality assurance, investing in a quality low resistance tester is not just beneficial—it's essential for ensuring optimal performance and safety in electrical systems.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy