machine that tests tensile strength factory

Understanding Tensile Strength Testing Machines An Industry Perspective

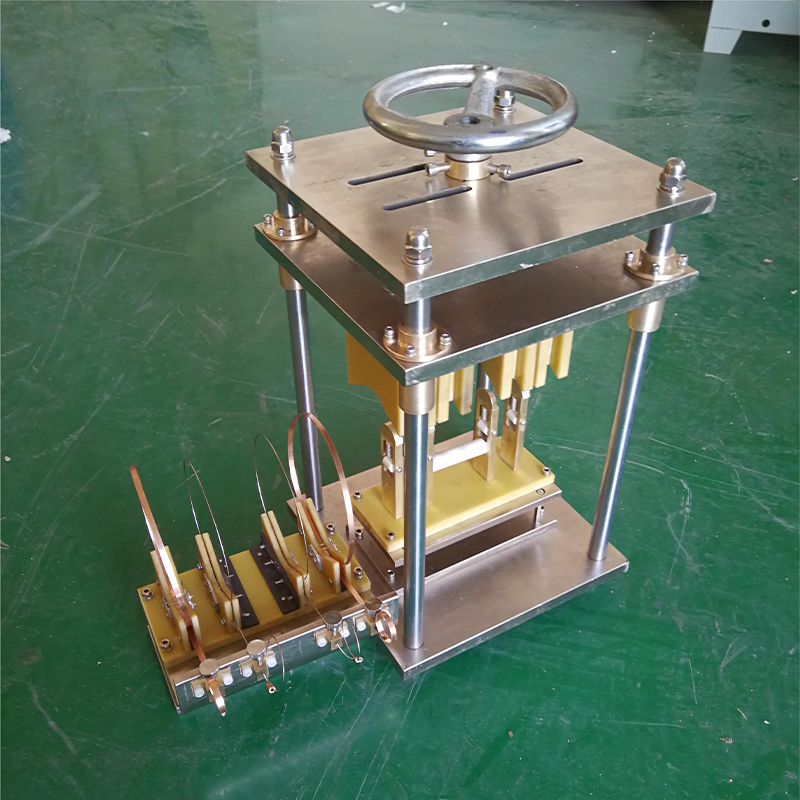

Tensile strength testing is a critical process in material science, engineering, and quality control in various industries. It measures how much force a material can withstand while being stretched or pulled before breaking. To ensure the safety and reliability of products, companies invest in tensile strength testing machines, which play a vital role in assessing material properties.

A tensile strength testing machine typically consists of a load frame, a grip system, a testing software system, and a load cell. The load frame houses the material specimen between two grips — one fixed and the other movable. As the movable grip pulls on the material, sensors measure the force exerted and the elongation of the sample until it reaches its breaking point. The data collected is then analyzed to determine the material's tensile strength, yield strength, and elongation percentage.

These machines are integral in sectors such as aerospace, automotive, construction, and textiles, where understanding the limits of materials is essential. For instance, in the aerospace industry, where safety is paramount, materials must endure extreme stress and conditions. Tensile strength testing ensures that the materials used in aircraft components meet strict standards.

machine that tests tensile strength factory

Factory-based tensile strength testing machines come in various types, including hydraulic, electromechanical, and servo-electric. Hydraulically powered machines are commonly utilized for heavy-duty applications due to their ability to generate high forces without compromising speed. On the other hand, electromechanical machines are favored for their precision and versatility, making them suitable for a wide range of materials, from metals to polymers.

With advancements in technology, modern tensile strength testing machines are increasingly equipped with smart features. These include automated data collection, real-time monitoring, and integrated analysis software that reduces human error and speeds up the testing process. Furthermore, remote access capabilities enable engineers to monitor tests from different locations, enhancing flexibility and response times.

In conclusion, tensile strength testing machines are indispensable tools in ensuring material integrity across various industries. Their role in quality assurance cannot be overstated, as they help prevent potential failures that could result in catastrophic consequences. As technology continues to evolve, the efficiency and accuracy of these machines will only improve, paving the way for safer and more reliable products in the global market. Investing in the right tensile strength testing equipment is, therefore, essential for any manufacturer committed to quality and safety standards.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy