Supplier of Machines for Testing Tensile Strength in Various Materials

Supplier of Tensile Strength Testing Machines Ensuring Material Integrity

In today's world, the reliability and safety of materials are of paramount importance across various industries. From construction to aerospace and automotive, the integrity of materials used determines the overall performance and safety of products. One of the critical tests conducted to evaluate this integrity is the tensile strength test. This test measures the force required to pull something to the point of failure, providing vital data necessary for quality assurance. Consequently, the role of suppliers offering tensile strength testing machines has never been more significant.

Tensile strength testing machines are sophisticated devices designed to apply controlled tension to a material specimen until it breaks. These machines typically consist of a load cell, a control system, and a software interface, all of which work together to deliver precise measurements of the material’s strength properties. The main purpose of these machines is to provide manufacturers and researchers with accurate data about how materials will behave under stress, enabling them to make informed decisions regarding material selection and application.

When selecting a supplier for tensile strength testing machines, several factors should be considered. First and foremost is the quality and precision of the equipment. Renowned manufacturers invest in advanced technology to ensure their machines provide reliable and repeatable results. These machines should come equipped with features such as digital displays, automatic data recording, and advanced software for analyzing results. Suppliers that prioritize accuracy can help clients achieve the high standards demanded by regulatory bodies and industry benchmarks.

Another important factor is the range of materials that can be tested. A good supplier will offer machines that can handle various materials, including metals, polymers, and composites. Different materials require different testing approaches—for example, steel may need a different testing configuration compared to a flexible polymer. Therefore, a versatile tensile strength testing machine can adapt to various materials and applications, making it a valuable asset for any laboratory or production facility.

machine that tests tensile strength supplier

Moreover, customer service and technical support are crucial elements in choosing a supplier. A reputable supplier should provide not only high-quality machines but also comprehensive support, including installation, calibration, and maintenance services. This kind of support ensures that clients can operate their machines at peak performance and that any issues can be resolved promptly, minimizing downtime and disruption to their operations.

Additionally, suppliers that offer training and educational resources for users can significantly enhance the experience of their clients. Understanding how to effectively use the machine and interpret the data is essential for maximizing the machine's capabilities. Well-informed users can carry out tests more efficiently and gain deeper insights from the test results, thereby improving their product development processes.

Finally, the supplier's reputation and customer feedback can serve as invaluable indicators of quality. Prospective buyers should seek testimonials and case studies that demonstrate the supplier's ability to deliver reliable tensile strength testing machines and support services. A strong track record in the industry is often reflective of a supplier's commitment to quality and customer satisfaction.

In conclusion, the importance of tensile strength testing machines cannot be overstated in ensuring material integrity across various industries. Choosing the right supplier is critical for obtaining a reliable, high-quality testing machine that meets specific needs. By considering factors such as machine quality, versatility, customer support, and supplier reputation, organizations can make informed decisions that enhance their material testing capabilities and, ultimately, product safety and performance. In a landscape where material integrity is key, the right tensile strength testing machine supplier can make all the difference.

-

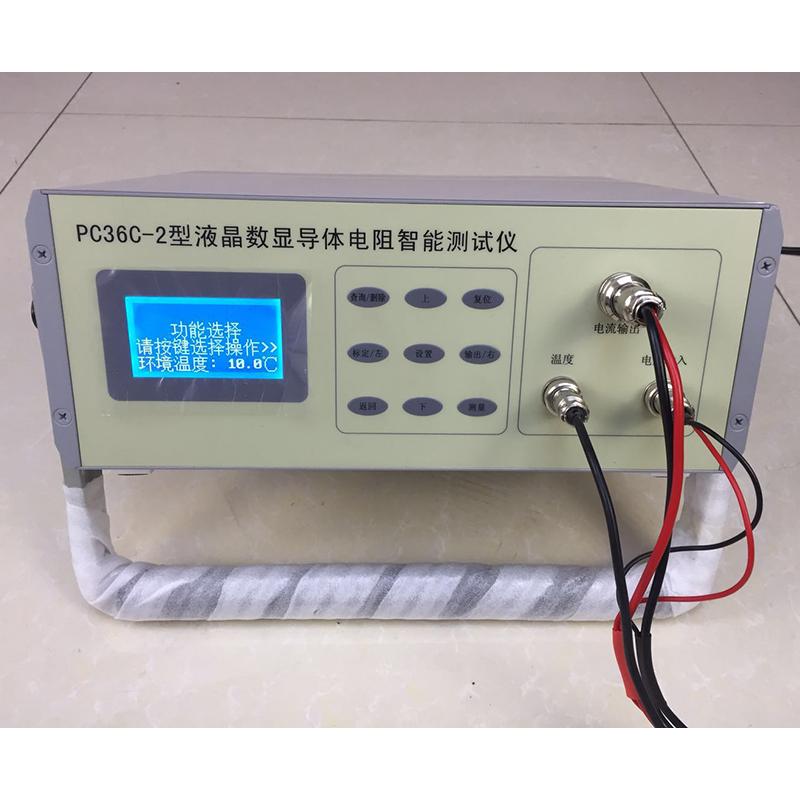

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy