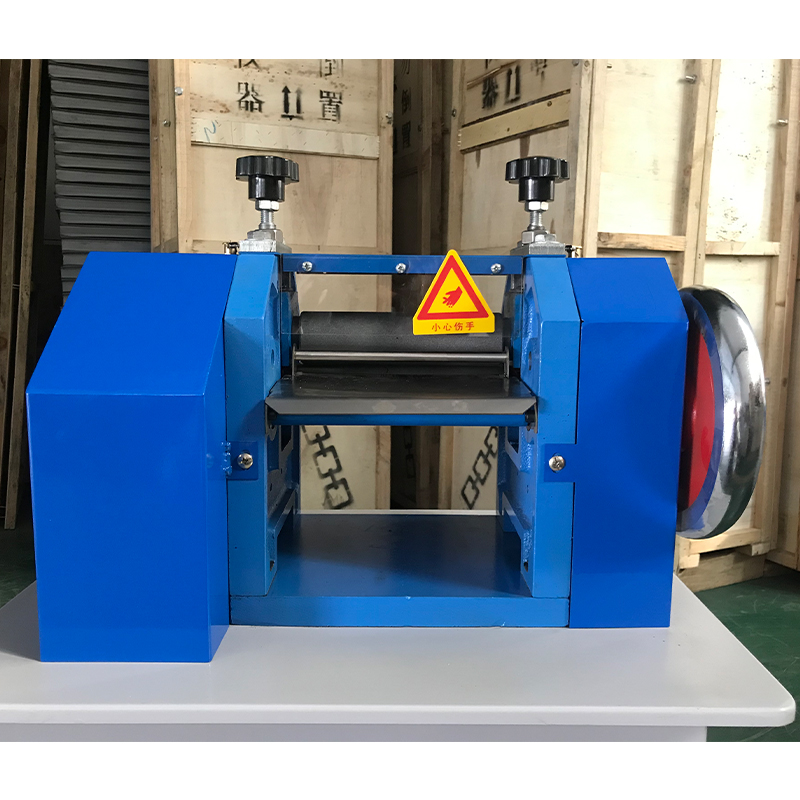

machine that tests tensile strength supplier

The Importance of Tensile Strength Testing Machines in Modern Industry

In the world of material science and engineering, understanding and measuring the tensile strength of materials is paramount. Tensile strength is defined as the maximum amount of tensile (stretching) stress that a material can withstand before it fails or breaks. This property is crucial for applications across various industries, including construction, manufacturing, aerospace, and automotive. To accurately measure the tensile strength of materials, specialized equipment known as tensile strength testing machines are employed. This article explores the significance of these machines, their types, applications, and the criteria for selecting a reliable supplier.

The Role of Tensile Strength Testing Machines

Tensile strength testing machines are designed to apply controlled tension to a material specimen until it breaks. The data collected during this process helps engineers and material scientists understand the material’s capabilities and limitations. The results can indicate how a material will behave under real-world conditions, providing essential insights for design and manufacturing processes.

One of the primary functions of these machines is to determine several key metrics, including yield strength, ultimate tensile strength, elongation, and reduction of area. Knowing these properties allows industries to select the appropriate materials for specific applications, ensuring safety, durability, and performance.

Types of Tensile Strength Testing Machines

Tensile strength testing machines come in various forms, each suited for different types of materials and testing requirements. The most common types include

1. Universal Testing Machines (UTMs) These versatile machines can test a wide range of materials, including metals, plastics, and composites. They are often equipped with advanced computer systems for data acquisition and analysis.

2. Electromechanical Testing Machines These machines use electric motors to apply tensile loads to specimens. They are praised for their precision and are suitable for testing smaller samples.

3. Hydraulic Testing Machines Utilizing hydraulic pressure, these machines can exert very high levels of force, making them ideal for testing larger or tougher materials.

machine that tests tensile strength supplier

4. Static and Dynamic Testing Machines Depending on the application, machines can perform static tests (slow load application) or dynamic tests (fast load application), helping to simulate real-life conditions the materials might face.

Applications Across Industries

The applications of tensile strength testing machines are widespread. In the construction sector, for example, these machines are vital for testing steel and concrete, ensuring that structures can withstand the forces they will be subjected to. In the automotive industry, understanding the tensile strength of materials determines the safety and performance of vehicles. Similarly, aerospace applications demand the highest standards of material performance due to the extreme conditions faced during flight.

Furthermore, with the rise of advanced manufacturing techniques such as 3D printing, tensile strength testing has become increasingly important in verifying material properties post-manufacturing, ensuring that the end products meet industry standards.

Selecting a Reliable Supplier

When choosing a supplier for tensile strength testing machines, several factors must be considered. A reputable supplier should offer machines that meet international standards such as ASTM and ISO, ensuring the accuracy and reliability of test results.

Additionally, the supplier should provide excellent customer service, offering training and support to ensure the proper usage and maintenance of the equipment. Features such as data management software, ease of integration with existing laboratory equipment, and options for customization can also influence purchasing decisions.

Finally, analyzing reviews and case studies from other customers can provide insights into the supplier's dependability and the quality of their machines.

Conclusion

Tensile strength testing machines play a crucial role in material evaluation and selection, impacting various industries' safety and quality. With the right machine, manufacturers and engineers can gain invaluable insights into their materials, ensuring they make informed decisions that lead to superior product performance. As technology continues to advance, the importance of these machines in fostering innovative manufacturing practices will only grow, underlining their essential role in modern industry.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy