machine to measure resistances companies

The Evolution and Importance of Machines to Measure Resistances in Industry

In the modern industrial landscape, precision and accuracy are paramount. One of the most critical measurements in various fields, including electronics, telecommunications, and manufacturing, is resistance. Machines designed to measure resistance play an essential role in ensuring products meet stringent quality standards and function correctly. This article explores the evolution, importance, and applications of resistance measurement machines in contemporary industry.

Historically, the measurement of electrical resistance dates back to the early experiments of physicists like Georg Simon Ohm in the 19th century. However, the development of sophisticated machines for measuring resistance has evolved significantly since then. Early devices were somewhat rudimentary, often requiring manual calibration and interpretation of readings. Today, advanced digital multimeters, micro-ohm meters, and automated testing systems are commonplace, offering precise measurements and user-friendly interfaces.

The core function of machines that measure resistance is to assess how strongly a material opposes the flow of electric current. This capability is crucial in various applications, including circuit design, materials testing, and quality assurance in manufacturing processes. Resistance measurement is essential for determining the electrical properties of materials, identifying defects in components, and ensuring compliance with industry standards.

In electronics manufacturing, for instance, measuring resistance is vital for testing circuit boards and components. A malfunctioning resistor or a compromised connection can lead to circuit failures. Machines to measure resistances ensure that every component meets its specifications before it is utilized in larger systems. This process not only saves time and resources but also enhances product reliability, ultimately benefiting consumers.

machine to measure resistances companies

Similarly, in the automotive sector, accurate resistance measurements are crucial for ensuring the safety and performance of electrical systems within vehicles. With the rise of electric vehicles and advanced driver-assistance systems (ADAS), the demand for precise resistance testing has grown. Machines designed for resistance measurement help manufacturers ensure that batteries, sensors, and electronic control units function correctly, contributing to overall vehicle safety and efficiency.

In addition to these applications, resistance measurement machines are also extensively used in research and development. Engineers and scientists rely on these devices to explore new materials, develop innovative technologies, and conduct experiments that require precise electrical characterizations. Laboratories equipped with advanced resistance measurement machines can explore groundbreaking research, potentially leading to technological advancements that reshape various industries.

As technology continues to evolve, so does the design and functionality of machines that measure resistances. Emerging trends, such as the integration of artificial intelligence and machine learning, promise further enhancements in measurement accuracy and efficiency. Future machines may be able to provide real-time data analysis and predictive maintenance, allowing industries to preemptively address potential malfunctioning components before they cause significant disruptions.

In conclusion, machines to measure resistances are indispensable tools in modern industrial applications. Their evolution from simple measuring devices to sophisticated digital systems underscores the importance of accuracy in electrical measurements. As industries continue to innovate, the role of resistance measurement machines will only expand, contributing to improved product quality, enhanced safety, and advancements in technology that drive the future of various sectors. Whether in electronics, automotive, or research, these machines remain at the forefront of ensuring electrical integrity and operational excellence.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

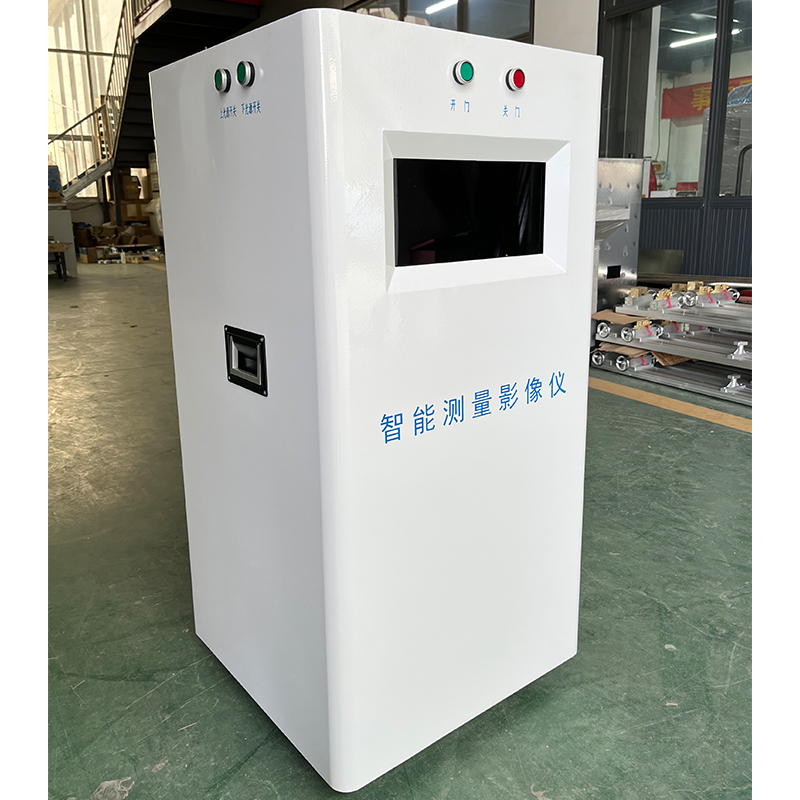

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy