machine to measure resistances factory

Machine to Measure Resistances Revolutionizing Quality Control in Factories

In the modern manufacturing landscape, precision and accuracy are paramount for ensuring quality and efficiency. One significant advancement that has streamlined quality control processes is the development of machines to measure resistances in various materials. These machines have become essential tools in factories, enhancing product reliability while reducing waste and production costs.

Understanding Resistance Measurement

Resistance measurement is a crucial aspect of electrical engineering and manufacturing. It refers to the detection of how much a material opposes the flow of electric current. This characteristic plays a vital role not only in electronics but also in various industrial applications, including material science, automotive, aerospace, and energy sectors. Understanding resistance helps manufacturers assess the quality and suitability of materials used in production.

The ability to measure resistance accurately is essential, as it can indicate flaws in materials that may lead to malfunctioning products. Traditional methods of measuring resistance often involve cumbersome manual techniques, which are prone to human error and can be time-consuming. This is where specialized machines designed for resistance measurement come into play, automating the process and enhancing reliability.

Features of Resistance Measuring Machines

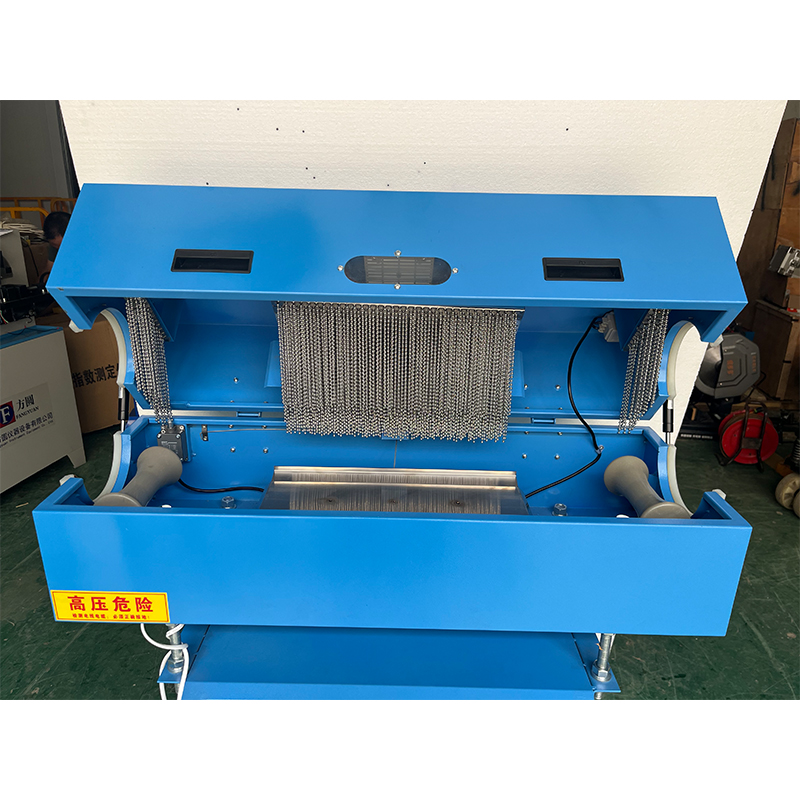

The machines designed to measure resistances typically come equipped with advanced features that allow for high precision and speed. They utilize various technologies, such as four-wire measurements, to eliminate the impact of lead resistance. Additionally, modern resistance measuring machines are often integrated with software that can analyze data in real-time, providing manufacturers with immediate insights into the quality of materials being used.

These machines can measure a wide range of resistances, suitable for various applications. From low resistances in conductive materials to high resistances in insulators, these machines are versatile and capable of meeting diverse industry needs. Furthermore, they provide visual and digital outputs, making it easier for quality control teams to interpret results and make informed decisions quickly.

Benefits in the Manufacturing Process

The integration of resistance measuring machines in factories offers numerous benefits

machine to measure resistances factory

2. Increased Efficiency Automating the resistance measurement process saves time and increases productivity, allowing manufacturers to expedite production timelines without compromising quality.

3. Cost Reduction By identifying defective materials early in the production process, manufacturers can significantly reduce waste and avoid the costs associated with producing faulty products.

4. Enhanced Quality Control Continuous monitoring of resistance levels allows for better quality assurance, leading to higher customer satisfaction and fewer returns or reworks.

5. Data Analysis and Traceability Advanced machines come with integrated software that logs measurements and trends. This data can be analyzed over time to improve manufacturing processes and ensure compliance with industry standards.

Applications Across Industries

Resistance measuring machines are employed in a multitude of industries. In the automotive sector, for instance, they are used to test wiring and electronic components, ensuring the safety and reliability of vehicles. In aerospace, these measurements are crucial for maintaining the integrity of materials used in aircraft construction. The energy sector benefits from resistance measurement by ensuring the efficiency and safety of transmission lines and components.

Moreover, with the rise of smart manufacturing and the Internet of Things (IoT), resistance measurement machines are increasingly being integrated into automated production lines. This integration supports real-time monitoring and control, leading to smarter and more responsive manufacturing environments.

Conclusion

The advent of sophisticated machines to measure resistances has transformed the landscape of manufacturing. By enhancing the quality control process, these machines not only ensure the reliability of products but also contribute to the overall efficiency and cost-effectiveness of production. As industries continue to evolve, the role of resistance measurement will undoubtedly expand, driving innovations in materials science and paving the way for even higher standards of quality in manufacturing. As we look to the future, it is clear that investing in advanced resistance measurement technology is not just a choice but a necessity for factories striving for excellence.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy