Manganese Steel Dumbbell Cutter: Precision Sample Preparation

Understanding the Manganese Steel Dumbbell Cutter in Modern Materials Testing

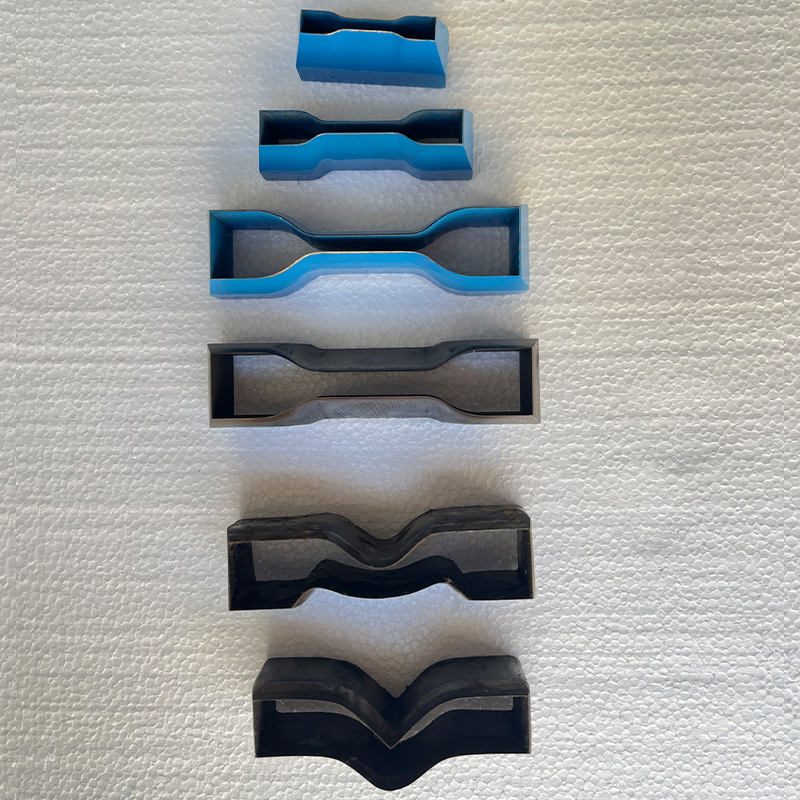

The Manganese Steel Dumbbell Cutter stands as a critical component in the realm of material science and quality control, primarily utilized for the precise preparation of dumbbell-shaped specimens for tensile strength testing. This specialized cutting tool is indispensable across a multitude of industries where the mechanical properties of materials, particularly polymers, plastics, elastomers, and various composite materials, must be rigorously assessed to meet stringent international standards. Its core function involves excising samples with specific dimensions and smooth edges, which is paramount for obtaining accurate and reproducible tensile test results, directly impacting product safety, reliability, and performance. The selection of manganese steel as the primary material for these cutters is deliberate, leveraging its exceptional hardness, wear resistance, and toughness, attributes that ensure the cutter maintains its sharp edge and dimensional integrity over prolonged periods of high-volume use. In sectors like automotive, aerospace, medical devices, and consumer goods manufacturing, where material failure can have significant consequences, the reliability and precision offered by a well-engineered Manganese Steel Dumbbell Cutter are not merely advantages but essential requirements for adherence to quality assurance protocols and compliance with industry regulations. The continued advancement in material science necessitates increasingly sophisticated and durable cutting solutions to keep pace with the evolving properties of new materials, solidifying the cutter's role as a cornerstone in analytical laboratories and production facilities worldwide.

Industry Trends and Market Dynamics Driving Demand for Manganese Steel Dumbbell Cutter Technology

The global market for material testing equipment, and by extension, precision sample preparation tools like the Manganese Steel Dumbbell Cutter, is experiencing robust growth driven by several key industry trends. A significant factor is the escalating emphasis on quality control and assurance across manufacturing sectors. With increasingly complex materials being developed—such as advanced polymers, high-performance composites, and bio-based plastics—the need for accurate and repeatable material characterization has become more critical than ever. This trend is further amplified by tightening regulatory standards and specifications, particularly in aerospace, automotive, and medical industries, which mandate rigorous testing protocols to ensure product safety and longevity. For instance, the demand for lightweight yet strong materials in electric vehicles (EVs) and sustainable packaging solutions directly correlates with an increased need for precise tensile testing, making the Manganese Steel Dumbbell Cutter an indispensable tool. Furthermore, the rise of Industry 4.0 and smart manufacturing initiatives encourages automation and data-driven decision-making in testing laboratories, where high-quality sample preparation is the foundational step for reliable data acquisition. The market is also seeing a shift towards more sustainable manufacturing practices, leading to the development of new recyclable and biodegradable materials that still require comprehensive mechanical property assessment. This ongoing innovation in materials science directly fuels the demand for durable, precise, and long-lasting sample preparation tools that can handle a wider range of material properties without degradation in performance. Manufacturers of testing equipment are continuously investing in R&D to enhance the durability and precision of cutters, responding to the industry's evolving needs for efficiency, accuracy, and longevity in their testing processes.

Key Technical Parameters and Specifications of a Precision Manganese Steel Dumbbell Cutter

The performance of a Manganese Steel Dumbbell Cutter is defined by a set of critical technical parameters that ensure its precision, durability, and compatibility with various material testing standards. These parameters dictate the quality of the prepared samples and, consequently, the reliability of tensile test results. Core specifications include the cutting edge material, where high-grade manganese steel, often alloyed with specific elements for enhanced hardness and wear resistance (e.g., Hadfield steel with 1.0-1.4% carbon and 11-14% manganese), is paramount. The cutter's hardness, typically measured in Rockwell (HRC), often ranges from 58-62 HRC, providing exceptional longevity and resistance to deformation under repeated use. Dimensional accuracy is another vital parameter, with typical tolerances for specimen width and length in accordance with international standards such as ISO 37, ISO 527, ASTM D412, and JIS K6251. For example, a common dumbbell shape, Type 1, might require a narrow section width of 6.0 ± 0.2 mm and a gauge length of 25.0 ± 0.5 mm. The cutting depth capabilities are also crucial, often up to 10-15 mm for thicker materials, ensuring versatility. Furthermore, the overall weight and dimensions of the cutter assembly are considered for integration into various cutting machines, ranging from manual presses to semi-automatic pneumatic or hydraulic systems. The surface finish of the cutting edges, measured in micrometers (µm) for roughness, directly impacts the smoothness of the specimen edges, minimizing stress concentration points that could skew tensile test results. Regular calibration and maintenance are essential to preserve these parameters, ensuring the cutter consistently produces specimens that meet the stringent requirements of modern materials engineering and quality assurance protocols.

| Parameter | Specification/Value | Notes |

|---|---|---|

| Material Composition | High-carbon Manganese Steel (e.g., ASTM A128) | Excellent wear resistance and toughness |

| Hardness | 58-62 HRC (Rockwell C Scale) | Ensures long-term edge retention |

| Specimen Standard Compliance | ISO 37, ISO 527, ASTM D412, JIS K6251, DIN 53504 | Conforms to international testing norms |

| Cutting Precision (Edge Smoothness) | Roughness (Ra) | Minimizes stress concentrations on specimens |

| Max. Cutting Thickness | Up to 15 mm (material dependent) | Versatility for various material gauges |

| Expected Lifespan | 100,000+ cuts (with proper maintenance) | High durability for continuous use |

| Compatibility | Manual, Pneumatic, Hydraulic Presses | Adaptable to various cutting machines |

The Advanced Manufacturing Process of a High-Performance Manganese Steel Dumbbell Cutter

The production of a high-quality Manganese Steel Dumbbell Cutter involves a meticulous multi-stage manufacturing process designed to impart superior hardness, wear resistance, and dimensional stability. It typically begins with the selection of premium-grade high-carbon manganese steel, renowned for its work-hardening properties. The initial phase often involves precision forging, where the steel is heated to a specific temperature and then shaped under immense pressure. This forging process refines the grain structure of the steel, eliminating internal defects and enhancing its overall toughness and fatigue resistance, making it ideal for high-stress cutting applications. Following forging, the blank undergoes multi-axis CNC (Computer Numerical Control) machining. This advanced machining technique allows for the precise shaping of the dumbbell profile and critical cutting edges with micron-level accuracy, ensuring that each cutter conforms exactly to the required specimen dimensions specified by ISO, ASTM, or JIS standards. The next crucial stage is heat treatment, which includes processes like austenitizing, quenching, and tempering. This carefully controlled thermal cycle is critical for achieving the optimal hardness (typically 58-62 HRC) and ductility in the manganese steel, preventing brittleness while maximizing cutting performance. After heat treatment, the cutter undergoes precision grinding and lapping. These finishing processes create the extremely sharp and smooth cutting edges necessary to produce defect-free specimens. Finally, each Manganese Steel Dumbbell Cutter is subjected to rigorous quality control inspections, including optical profilometry to verify edge sharpness and surface finish, dimensional checks using CMM (Coordinate Measuring Machine) systems, and destructive testing of sample cuts to ensure the integrity of the specimen produced. This comprehensive manufacturing and testing regime guarantees a product with exceptional longevity, consistent performance, and adherence to the highest industry standards, ensuring reliable tensile test results in petrochemical, metallurgical, and other demanding sectors.

Technical Advantages and Performance Benefits of Utilizing a Premium Manganese Steel Dumbbell Cutter

Opting for a premium Manganese Steel Dumbbell Cutter offers a distinct array of technical advantages and performance benefits that significantly enhance laboratory efficiency and testing accuracy. Foremost among these is the exceptional durability derived from manganese steel's inherent toughness and work-hardening capabilities. Unlike conventional tool steels, manganese steel develops an extremely hard surface when subjected to impact and abrasion during the cutting process, effectively self-sharpening and extending its operational lifespan significantly. This extended longevity translates into reduced replacement costs and minimized downtime for tool changes, directly contributing to operational cost savings. Secondly, the precision afforded by a well-manufactured Manganese Steel Dumbbell Cutter is unparalleled. Its finely ground and honed edges produce specimens with consistently smooth, defect-free contours, free from micro-cracks or stress risers that could prematurely initiate failure during tensile testing. This consistency is crucial for obtaining reliable and reproducible test data, ensuring compliance with rigorous quality standards such as ISO and ASTM, and facilitating accurate material characterization. Furthermore, the robust design allows for efficient cutting across a wide range of materials, from thin films to thick sheets of rubber, plastics, and even some soft composites, without requiring frequent resharpening or recalibration. The anti-corrosion properties of treated manganese steel also extend its utility in diverse industrial environments, including those with high humidity or exposure to certain chemicals, particularly relevant in petrochemical or water treatment industries. In essence, the investment in a high-grade Manganese Steel Dumbbell Cutter translates into superior specimen quality, enhanced testing reliability, prolonged tool life, and ultimately, a more efficient and cost-effective material testing operation.

Diverse Application Scenarios for the Manganese Steel Dumbbell Cutter

The versatility and precision of the Manganese Steel Dumbbell Cutter make it an essential tool across a broad spectrum of industrial and research applications where accurate material tensile testing is paramount. In the automotive industry, it is critical for preparing samples from various plastic components, rubber seals, and composite parts used in vehicle interiors, exteriors, and engine compartments. This ensures the materials meet strict safety and performance criteria, contributing to vehicle reliability and crashworthiness. The aerospace sector similarly relies on these cutters for composite materials, sealants, and polymeric components, where material integrity under extreme conditions is non-negotiable for flight safety. In medical device manufacturing, where biocompatibility and mechanical strength are vital, the cutter is used to prepare specimens from polymers used in catheters, tubing, and surgical implants, ensuring they meet rigorous regulatory standards like FDA requirements. The packaging industry employs these cutters extensively for films, foils, and flexible packaging materials to assess their tensile strength, tear resistance, and elongation, crucial for product protection and shelf life. Furthermore, in research and development laboratories, particularly those focused on new material synthesis, the Manganese Steel Dumbbell Cutter facilitates precise sample preparation for fundamental mechanical property characterization, accelerating the innovation cycle. The broad utility of this tool underscores its foundational role in ensuring material quality and performance across these diverse, high-stakes environments, directly impacting product development, quality assurance, and regulatory compliance. Its ability to consistently produce uniform specimens for a range of materials underpins critical material science investigations and industrial quality control.

Customization Solutions and Tailored Engineering for Manganese Steel Dumbbell Cutter Designs

While standard Manganese Steel Dumbbell Cutter designs cater to the most common international testing standards, many industries and specialized applications require bespoke solutions to accommodate unique material properties or non-standard specimen geometries. Leading manufacturers offer comprehensive customization services, providing tailored engineering expertise to meet these precise demands. This customization often begins with a thorough consultation to understand the specific material (e.g., highly elastic elastomers, brittle ceramics, or anisotropic composites), the required specimen dimensions, and the testing standard that needs to be met, even if it's an internal company standard. Based on these inputs, engineers can design and manufacture cutters with modified gauge lengths, widths, or even entirely different sample shapes (e.g., rings, strips) while retaining the core benefits of manganese steel durability. This process may involve advanced CAD/CAM modeling to simulate cutting performance and optimize the die geometry for specific material characteristics, minimizing stress concentrations during cutting. Furthermore, custom surface coatings or specialized heat treatments can be applied to enhance wear resistance or provide anti-stick properties for highly adhesive materials. For instance, in the rubber industry, where specific ASTM or ISO standards dictate precise dumbbell shapes for various elastomers, a customized Manganese Steel Dumbbell Cutter ensures perfect conformity, even for experimental or new polymer formulations. This capability for bespoke design extends to compatibility with existing cutting presses, whether manual, pneumatic, or hydraulic, ensuring seamless integration into current laboratory setups. The ability to provide customized Manganese Steel Dumbbell Cutter solutions is a testament to a manufacturer's technical proficiency and commitment to serving diverse client needs, enabling optimal sample preparation for even the most challenging material testing scenarios.

Comparative Analysis: Standard vs. High-Performance Manganese Steel Dumbbell Cutter

When selecting a Manganese Steel Dumbbell Cutter, it is crucial to understand the distinctions between standard-grade and high-performance options, as these differences significantly impact operational efficiency, long-term costs, and the reliability of test results. Standard cutters, while generally meeting basic dimensional requirements, may utilize a more generic manganese steel alloy or less precise manufacturing techniques. This can lead to a shorter lifespan, requiring more frequent replacements and resharpening, increasing overall maintenance expenditures. Furthermore, the edge quality of standard cutters might be less consistent, potentially introducing minor defects or inconsistencies in the cut specimens, which can manifest as scatter in tensile test data and compromise the accuracy of material characterization. In contrast, high-performance Manganese Steel Dumbbell Cutter units are typically crafted from premium-grade, highly specialized manganese steel alloys, often with optimized carbon and manganese content, sometimes incorporating additional alloying elements to enhance specific properties. Their manufacturing process involves advanced techniques like precision CNC grinding, multi-stage heat treatment, and cryogenic tempering, which result in superior hardness (e.g., consistently at the higher end of the 58-62 HRC range) and an exceptionally fine, durable cutting edge. This meticulous production yields a cutter with significantly extended operational life, often performing over 100,000 cuts without noticeable degradation in edge quality. The superior edge precision of high-performance cutters ensures virtually flawless specimen preparation, leading to highly accurate and reproducible tensile test results, which is invaluable for critical applications in R&D, aerospace, and medical sectors. While the initial investment for a high-performance cutter may be higher, its long-term cost-effectiveness, reduced downtime, and enhanced data reliability often make it the superior choice for professional laboratories and high-volume production environments.

| Feature | Standard Cutter | High-Performance Cutter |

|---|---|---|

| Material Quality | Generic Manganese Steel | Premium, Optimized Manganese Steel Alloy |

| Hardness (HRC) | 56-59 | 59-62+ (Consistently Higher) |

| Manufacturing Precision | Good (CNC Machining) | Excellent (Precision CNC Grinding, Lapping) |

| Cutting Edge Quality | Good, may degrade faster | Superior, extremely smooth, long-lasting |

| Expected Lifespan (Cuts) | ~50,000 | 100,000+ |

| Specimen Edge Finish | Acceptable, minor irregularities possible | Virtually flawless, minimal stress points |

| Cost (Initial) | Lower | Higher |

| Overall Value | Suitable for low-volume, less critical tests | Optimal for high-volume, critical, and R&D applications |

Real-world Application Cases and Client Success with Manganese Steel Dumbbell Cutter

The proven efficacy of the Manganese Steel Dumbbell Cutter is best illustrated through its successful deployment in various demanding industrial settings. A prominent automotive supplier, for example, producing interior plastic components for electric vehicles, experienced a significant reduction in tensile testing data variability after upgrading to high-precision Manganese Steel Dumbbell Cutter dies. Previously, inconsistencies in sample preparation led to a higher rate of retesting, impacting production timelines. With the improved cutter, they achieved tighter statistical process control, reducing material waste by 15% and accelerating product validation cycles by 10%. In another instance, a leading manufacturer of high-performance conveyor belts in the mining industry faced challenges with accurately assessing the tensile strength of their new elastomer compounds designed for extreme abrasion resistance. Their existing cutters struggled with the thick, tough materials, resulting in irregular sample edges and unreliable test data. Upon implementing a customized Manganese Steel Dumbbell Cutter tailored for their specific material thickness and hardness, they reported a 20% improvement in the consistency of their tensile strength measurements and a 30% increase in cutter lifespan compared to their previous tools. Similarly, a research institution developing advanced polymeric films for sustainable packaging noted a marked improvement in the reproducibility of their tensile test results. The precision offered by the Manganese Steel Dumbbell Cutter was instrumental in characterizing the mechanical properties of experimental films, which allowed them to iterate designs more rapidly and accurately predict field performance. These case studies underscore the critical role that a superior Manganese Steel Dumbbell Cutter plays in achieving operational excellence, enhancing product quality, and accelerating innovation across diverse industrial applications, demonstrating tangible returns on investment through improved efficiency and data integrity.

Authoritativeness and Trustworthiness: Our Commitment to Quality and Support

Our dedication to providing top-tier Manganese Steel Dumbbell Cutter solutions is underpinned by a steadfast commitment to industry authority and client trustworthiness. We adhere rigorously to internationally recognized quality management systems, evidenced by our ISO 9001 certification, ensuring that every stage from material sourcing to final product inspection meets the highest global standards. Our manufacturing processes are also compliant with environmental management standards such as ISO 14001, reflecting our commitment to sustainable practices. For over two decades, we have partnered with leading research institutions, material science universities, and Fortune 500 companies across sectors like automotive, aerospace, and medical devices, providing bespoke and standard cutting solutions that consistently exceed performance expectations. Our long-standing service record, coupled with numerous positive client testimonials and repeat business, underscores our reputation as a trusted provider. Each Manganese Steel Dumbbell Cutter undergoes extensive in-house testing, utilizing advanced metrology equipment and actual cutting performance tests, with data meticulously recorded and available upon request, offering complete transparency into our product quality. Furthermore, we provide a robust warranty period, typically 12-24 months, against manufacturing defects, demonstrating our confidence in the durability and precision of our cutters. Our customer support team comprises experienced technical specialists ready to assist with product selection, application guidance, and troubleshooting, ensuring seamless integration and optimal performance in your testing environment. We also offer comprehensive maintenance and resharpening services to extend the lifespan of your cutters, emphasizing long-term partnership over singular transactions. This holistic approach, combining certified quality, extensive experience, and unwavering support, establishes us as an authoritative and trustworthy partner for all your material sample preparation needs.

Frequently Asked Questions (FAQ) about Manganese Steel Dumbbell Cutter

To further enhance transparency and address common queries, we have compiled a list of frequently asked questions regarding the Manganese Steel Dumbbell Cutter, providing clarity on its usage, maintenance, and benefits. Q1: What materials can a Manganese Steel Dumbbell Cutter effectively cut? A: These cutters are primarily designed for non-metallic materials such as various types of rubbers (e.g., natural rubber, SBR, EPDM), thermoplastics (e.g., PVC, PE, PP), thermosets, films, sheets, foam, leather, and certain composite materials. While highly durable, they are not intended for cutting metals or extremely brittle ceramics. Q2: How often should a Manganese Steel Dumbbell Cutter be resharpened? A: The resharpening frequency largely depends on the material being cut and the volume of use. For high-performance cutters processing typical elastomers or plastics, resharpening might be needed after 50,000 to 100,000 cuts. For abrasive materials, it might be sooner. We recommend monitoring specimen edge quality; any signs of rough edges or inconsistent dimensions indicate a need for professional resharpening. Q3: Can these cutters be used with any type of cutting press? A: Our Manganese Steel Dumbbell Cutter designs are compatible with most standard cutting presses, including manual, pneumatic, and hydraulic models. It's crucial to ensure the press has adequate force for the material thickness and that the cutter's base dimensions match the press's mounting platform. We provide specifications for compatibility to ensure proper fit and function. Q4: What is the typical lead time for a customized Manganese Steel Dumbbell Cutter? A: Lead times for customized cutters vary based on design complexity and current production schedules. Typically, custom orders are fulfilled within 4-8 weeks from design approval. Standard cutters are often available for immediate shipment. We provide accurate lead time estimates upon quotation. Q5: What kind of warranty and after-sales support do you offer? A: We offer a standard 12-month warranty against manufacturing defects for all our cutters. Our dedicated technical support team is available for assistance, offering guidance on proper usage, maintenance, and troubleshooting to maximize the lifespan and performance of your Manganese Steel Dumbbell Cutter. We also provide professional resharpening and refurbishment services.

Conclusion: The Enduring Value of Precision in Material Testing

In conclusion, the Manganese Steel Dumbbell Cutter is far more than a simple tool; it is a critical instrument that underpins the accuracy and reliability of material tensile strength testing across countless industries. Its unique combination of material properties – superior hardness, exceptional wear resistance, and inherent toughness – ensures the production of highly consistent, defect-free specimens, which are indispensable for obtaining precise and reproducible test data. As industries continue to innovate with advanced materials and face ever-tightening regulatory scrutiny, the demand for such high-precision sample preparation tools will only intensify. The technical advantages offered by a premium Manganese Steel Dumbbell Cutter, including extended lifespan, reduced maintenance, and superior specimen quality, translate directly into significant long-term cost savings and enhanced operational efficiency for laboratories and production facilities. Investing in a high-quality Manganese Steel Dumbbell Cutter is not merely an expense but a strategic decision that contributes to product integrity, reduces risks associated with material failure, and accelerates research and development cycles. Coupled with comprehensive technical support, robust warranty offerings, and the flexibility of customization, these cutters represent a fundamental pillar in the pursuit of material excellence, enabling companies to confidently develop, test, and deploy products that meet the highest standards of quality and performance in a competitive global market. The future of material science and engineering will continue to rely heavily on the foundational accuracy provided by such precision instruments.

References

- ASM Handbook, Volume 1: Properties and Selection: Irons, Steels, and High-Performance Alloys. ASM International, 1990.

- ISO 37:2017, Rubber, vulcanized or thermoplastic — Determination of tensile stress-strain properties.

- ASTM D412-16, Standard Test Methods for Vulcanized Rubber and Thermoplastic Elastomers—Tension.

- Kalpakjian, S., & Schmid, S. R. Manufacturing Engineering and Technology. Pearson, 2014.

- Callister, W. D., & Rethwisch, D. G. Materials Science and Engineering: An Introduction. John Wiley & Sons, 2018.

- "The Science of Manganese Steels," Metallurgical and Materials Transactions A, Springer.

-

The Role of Tensile Force Testers in Quality Control and Material Science

NewsAug.01,2025

-

Maintenance and Safety Tips for Aging Ovens

NewsAug.01,2025

-

Density Balance in Forensic Science

NewsAug.01,2025

-

Advanced Optical Measurement Technologies

NewsAug.01,2025

-

A Buyer’s Guide to Tensile Test Machines

NewsAug.01,2025

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy