manual tensile tester exporters

Exploring Manual Tensile Testers Importance and Market Trends

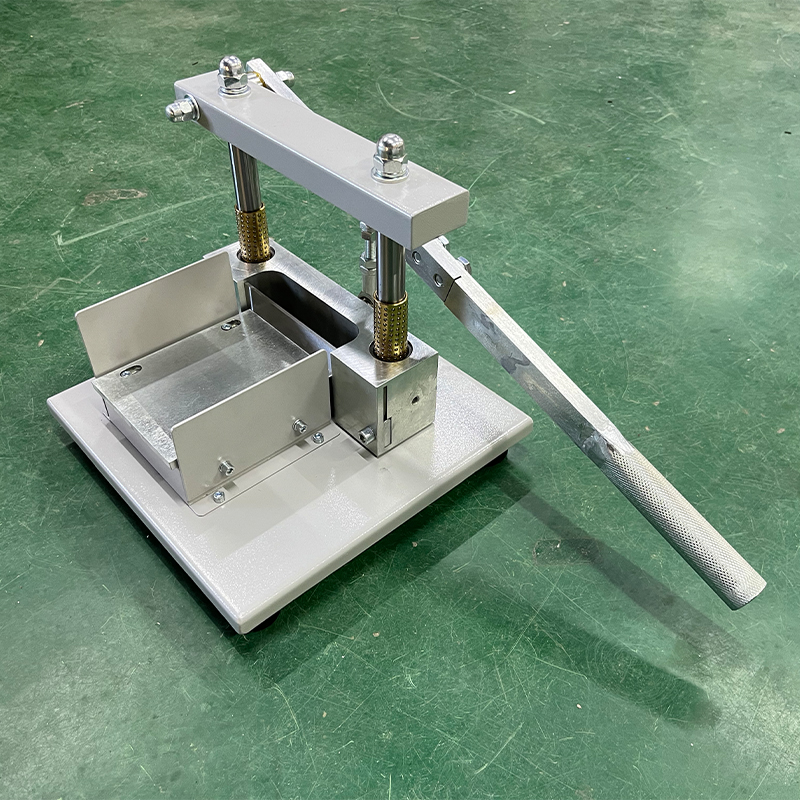

In the realm of material testing, the significance of tensile testers cannot be overstated. Manual tensile testers, in particular, are pivotal in evaluating the tensile strength and ductility of materials. Widely used in various industries such as construction, manufacturing, and materials science, these devices provide critical data on how materials behave under stress. As global demand for quality assurance and material reliability grows, the market for manual tensile testers is witnessing a notable transformation.

Understanding Manual Tensile Testers

Manual tensile testers are mechanical devices that enable users to conduct tensile tests on materials such as metals, plastics, and composites. The basic functionality involves pulling a specimen until it fails, allowing for the measurement of key parameters such as ultimate tensile strength, yield strength, and elongation. The simplicity of manual testers makes them accessible for smaller laboratories, educational institutions, and onsite testing environments.

These testers are preferred for their straightforward operation and cost-effectiveness compared to automated systems. Users manually initiate the test, which allows for a more hands-on understanding of the material's properties. The data obtained is invaluable for engineers and researchers, guiding them in product development and quality control processes.

The Market Landscape

The global market for manual tensile testers is characterized by a mix of established players and emerging manufacturers. Key exporters of manual tensile testers include countries with a robust engineering and manufacturing background. Regions such as Europe, North America, and parts of Asia, particularly China and India, are significant contributors to the export market.

manual tensile tester exporters

As the trends in manufacturing shift towards sustainability and innovation, exporters are focusing on developing advanced features for manual tensile testers. For instance, integrating digital readouts, data logging capabilities, and custom fixtures are becoming more common. This evolution is driven by the industry's demand for precise measurements and ease of data analysis.

Challenges and Opportunities

Despite the promising market dynamics, several challenges linger. Manual tensile testers often require skilled operators to ensure accuracy and reproducibility of results. Additionally, competition from automated systems that offer higher throughput can make it challenging for manual testers to maintain relevance in high-volume environments.

Nevertheless, there are numerous opportunities for growth. As industries increasingly seek to balance quality with cost-effectiveness, manual tensile testers can carve out a niche by focusing on customization and user-friendly designs. Furthermore, the rise in educational institutions and small-scale research facilities presents an avenue for manual tensile tester manufacturers to expand their customer base.

Conclusion

In conclusion, manual tensile testers are integral tools in the material testing landscape. As industries continue to prioritize material performance and safety, the demand for these testers is likely to grow. Exporters that innovate and adapt to market needs will find ample opportunities to thrive in this evolving sector. By providing reliable, accurate, and user-friendly testing solutions, they can ensure that manual tensile testers remain a cornerstone in quality assurance across various industries.

-

Precision Tools: Your Key To Accurate Measurements

NewsSep.01,2025

-

Precision Tools For Wire And Cable Testing

NewsSep.01,2025

-

Precision Testing Equipment For Electrical And Material Analysis

NewsSep.01,2025

-

Precision At Your Fingertips: Projector Measurements

NewsSep.01,2025

-

Optical Measurement: Precision At Your Fingertips

NewsSep.01,2025

-

Cable And Smoke Testing

NewsSep.01,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy