manual tensile tester machine factories

Manual Tensile Tester Machine Factories An Overview

In the realm of material testing, the manual tensile tester machine stands out as a fundamental piece of equipment utilized across various industries. These machines are primarily designed to evaluate the tensile properties of materials, including their strength, ductility, and yield points. The manufacturers of these machines play a crucial role in ensuring that industries—from construction to manufacturing—have access to reliable and precision-engineered testing equipment.

Understanding Manual Tensile Testers

Manual tensile testers operate by applying a uniaxial force to a sample material until it either yields or fractures. This process provides invaluable data regarding the material’s elasticity, tensile strength, and ultimate breaking point. Unlike automated systems, manual testers require a human operator to oversee the testing process, which can result in a more engaged analysis of the material's performance.

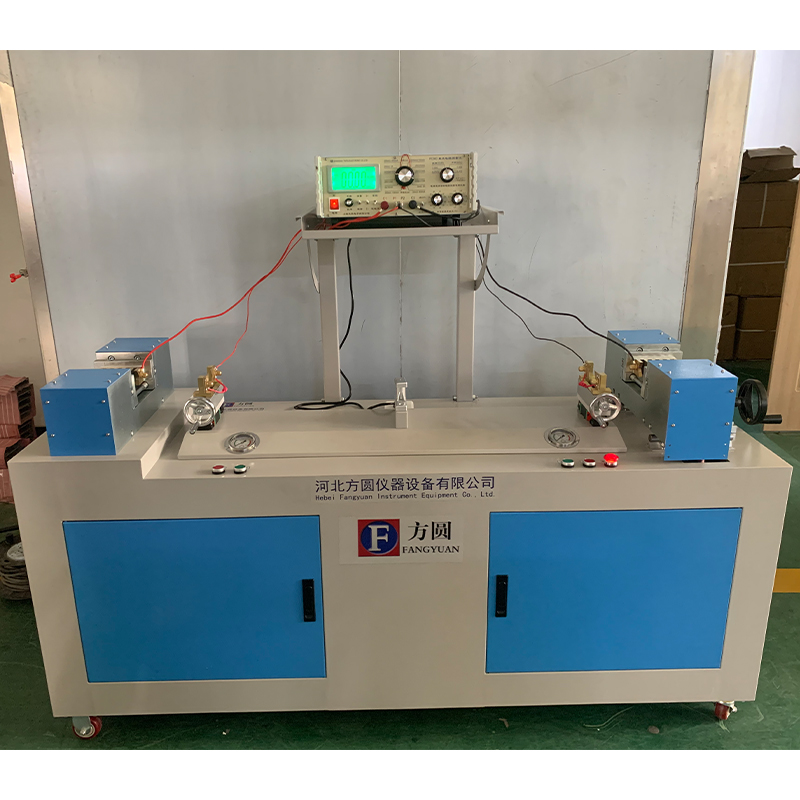

Typical components of a manual tensile tester include a crosshead that moves vertically to apply force, grips for holding the sample, and a gauge to measure deformation

. The simplicity of these machines enables labs with limited budgets to conduct comprehensive tensile tests without the high costs associated with fully automated setups.Factories Producing Manual Tensile Testers

manual tensile tester machine factories

The landscape of manual tensile tester manufacturing is diverse, with factories spread across various regions known for engineering precision and adherence to quality standards. In countries like Germany, the United States, and Japan, factories are often equipped with advanced technologies that ensure the production of durable and accurate testing machines. These facilities typically employ skilled technicians and engineers who are dedicated to innovation and quality control.

Manufacturers may offer a selection of models tailored to specific testing needs, including options for varying sample sizes and material types. Additionally, many factories focus on providing customization, allowing clients to modify features to suit their particular testing requirements. This customer-centric approach not only enhances user experience but also fosters greater satisfaction and loyalty among clients.

Quality Control and Certification

To maintain competitiveness, factories producing manual tensile testers often emphasize rigorous quality control measures. Certifying bodies, such as the International Organization for Standardization (ISO) and American Society for Testing and Materials (ASTM), play a critical role in setting standards that these manufacturers must adhere to. Regular audits and inspections ensure that each machine produced meets the predefined specifications for accuracy and reliability.

Conclusion

In conclusion, manual tensile tester machine factories are vital contributors to the field of material testing. Their commitment to producing high-quality machines enhances the ability of industries to assess material performance effectively. As technology continues to evolve, these factories are well-positioned to meet the growing demands for more sophisticated testing solutions, ensuring that professionals have the tools they need to maintain safety and quality in their products. The ongoing investment in quality and innovation will undoubtedly drive the future of material testing equipment manufacturing.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy