Measuring Equipment Solutions for Cable Manufacturing Companies to Enhance Efficiency and Precision

Measuring Machines for Cable Companies Ensuring Precision and Quality in Manufacturing

In the world of cable manufacturing, precision is not just a luxury; it is an absolute necessity. The integrity of electrical cables, whether used for telecommunications, power distribution, or industrial applications, hinges on their design and manufacturing quality. As companies in this sector strive to meet global standards and consumer expectations, the adoption of advanced measuring machines becomes indispensable. These sophisticated tools not only enhance the accuracy of production processes but also significantly improve product quality and operational efficiency.

Measuring machines come in various forms, each designed to meet specific requirements in the cable manufacturing process. Among the most common types are coordinate measuring machines (CMMs), optical measuring systems, and laser measurement devices. Each machine serves a unique purpose, from measuring the diameter and thickness of insulation materials to evaluating the physical properties of different conductive elements within the cables.

The Role of Technology in Measurement

In recent years, the role of technology in measuring machines has evolved dramatically. Advanced software solutions integrated with measuring devices provide manufacturers with detailed analytics, enabling them to monitor production in real time. This capability is crucial for identifying deviations from set specifications early in the manufacturing process, minimizing waste, and ensuring that only the highest quality cables reach the market.

The introduction of 3D measurement technology has further revolutionized the cable production industry. Traditional measurement methods often rely on two-dimensional assessments, which can lead to inaccuracies in complex cable designs. In contrast, 3D measurement machines create detailed topographical maps of cable components, ensuring that every aspect of the cable—such as its shape, size, and surface texture—is meticulously evaluated.

Boosting Efficiency and Reducing Costs

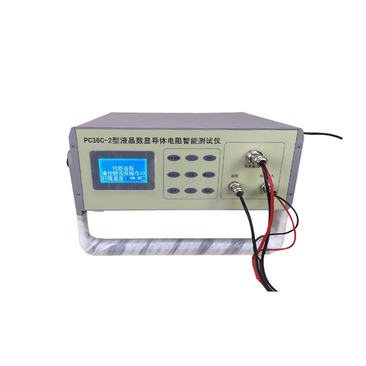

measure machine for cables companies

Implementing these high-precision measuring machines not only boosts the quality of cable products but also enhances manufacturing efficiency. Automated measurement processes reduce the time workers spend on manual checks, allowing them to focus on other critical aspects of production. This streamlining of operations can lead to significant cost savings for cable companies, enabling them to respond more effectively to market demands and reduce lead times for new cable designs.

Furthermore, the consistent use of measuring equipment helps in maintaining compliance with industry regulations and standards, which are paramount for companies operating in sectors such as telecommunications and energy. By ensuring their products meet stringent requirements, cable manufacturers can avoid costly recalls and maintain a strong reputation in the marketplace.

Training and Expertise Essential Components

While the machines themselves are integral to the measuring process, the effectiveness of these tools is greatly enhanced by the expertise of the operators. Training personnel to properly utilize measuring machines is a crucial step in optimizing their potential. Employees must understand not only how to operate the equipment but also how to interpret the data generated effectively. Investing in ongoing training and skill development helps ensure that personnel remain updated on the latest technologies and measurement techniques, which can further elevate product quality and efficiency.

The Future of Measuring Machines in Cable Production

As the cable manufacturing industry continues to evolve, the future of measuring machines looks promising. Innovations such as artificial intelligence (AI) and machine learning are set to further improve measurement accuracy and efficiency. These technologies can analyze vast amounts of production data to identify trends and forecast potential issues before they arise, allowing for proactive adjustments in the manufacturing process.

In conclusion, measuring machines play a pivotal role in the success of cable companies. Their ability to ensure precision, improve quality, and enhance operational efficiency is indispensable in a highly competitive market. As technology advances, cable manufacturers that embrace these innovations will not only elevate their production standards but also secure their place as leaders in the industry. The integration of cutting-edge measuring solutions will undoubtedly lead to a new era of productivity and reliability in cable manufacturing.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy