Measuring Equipment Solutions for Cable Manufacturing and Quality Assurance

Measuring Machines Elevating Cable Quality in the Manufacturing Industry

In the competitive landscape of cable manufacturing, quality assurance is paramount. As manufacturers strive to produce cables that meet stringent industry standards and customer expectations, the adoption of advanced measuring machines has become a game changer. These state-of-the-art devices not only enhance the accuracy of measurements but also streamline production processes, ultimately leading to higher quality products.

Measuring Machines Elevating Cable Quality in the Manufacturing Industry

One of the most significant benefits of utilizing measuring machines in cable production is their ability to automate the testing process. Traditional manual measurement methods can be time-consuming and susceptible to human error. In contrast, automated measuring machines offer high-speed testing capabilities, enabling manufacturers to process large volumes of cables in a fraction of the time it would take using manual methods. This efficiency not only leads to cost savings but also allows for quicker product turnaround, giving companies a competitive edge.

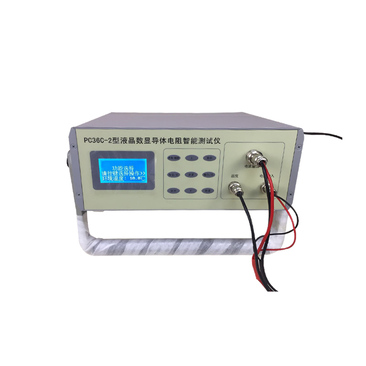

measure machine for cables company

Moreover, the integration of digital technology into measuring machines has revolutionized the way manufacturers handle quality control. Modern machines often feature software that can analyze data in real-time, providing instant feedback and alerts if measurements fall outside of acceptable ranges. This immediate response capability empowers manufacturers to make on-the-spot adjustments to the production process, maintaining high standards of quality without significant downtime.

Additionally, measuring machines contribute to the overall sustainability of the cable manufacturing process. By ensuring that products meet quality standards, manufacturers can minimize waste generated by defective products. Reducing scrap material not only leads to cost savings but also aligns with global efforts to create more sustainable manufacturing practices.

As the cable industry continues to evolve, the demand for high-quality products will only increase. Manufacturers must stay ahead of the curve by investing in advanced measuring technologies. Whether it’s through laser measurement systems, optical gauges, or specialized testing equipment, the focus must remain on precision and reliability.

In conclusion, measuring machines are an essential component of modern cable manufacturing, significantly enhancing quality control and operational efficiency. By automating testing processes, providing real-time data analysis, and reducing waste, these machines play a critical role in ensuring the production of high-quality cables. As manufacturers continue to prioritize quality and sustainability, the importance of incorporating advanced measuring technologies will only grow, ultimately contributing to the success and innovation within the industry.

-

Reliable Performance Testing with Advanced Aging Chamber Solutions

NewsAug.23,2025

-

Advancing Precision with Profile Projector Technology

NewsAug.23,2025

-

UV-LED Ultraviolet Crosslinking Technology: Innovation and Prospects

NewsAug.23,2025

-

Ensuring Safety and Compliance

NewsAug.23,2025

-

Electrical Properties Testing in Modern Applications

NewsAug.23,2025

-

Universal Tensile Testing Machine Applications in Modern Electrical and Material Testing

NewsAug.23,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy