Measuring Devices for Exporters of Cable Products

Measuring Machines for Cable Exporters A Comprehensive Overview

In the fast-evolving world of international trade, particularly in the domain of cable exports, precision and quality assurance remain paramount. One critical component that manufacturers and exporters must consider is the efficiency and accuracy of their measuring machines. This article delves into the importance of measuring machines for cable exporters, the different types available, and how these tools enhance operational efficiency.

Importance of Measuring Machines

Cable manufacturing involves strict adherence to dimensional tolerances and quality standards. Cables must meet specific criteria regarding their diameter, insulation thickness, conductor size, and overall length. Any deviation from these parameters can lead to failures in application, safety hazards, and ultimately, financial loss for exporters. Measuring machines are essential for ensuring that cables conform to the required specifications before they leave the factory and are shipped to customers worldwide.

Types of Measuring Machines

1. Length Measuring Machines Length accuracy is critical in cable production. Length measuring machines ensure that each cable produced meets the specified length requirements. These machines utilize various technologies, including laser measurement systems and rotary encoders, to achieve high precision.

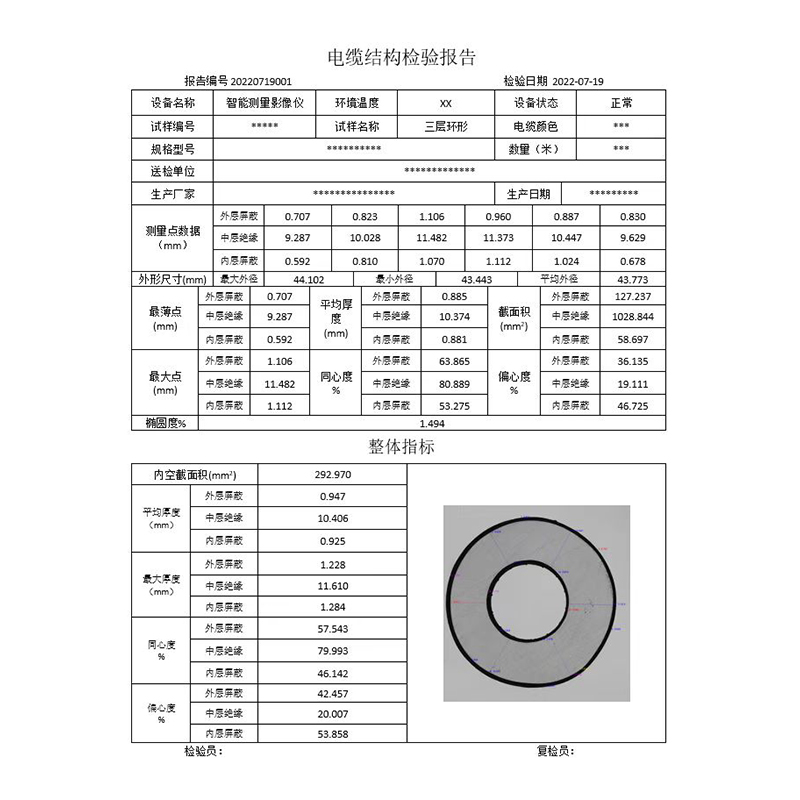

2. Diameter Measuring Machines The diameter of a cable is a crucial aspect that affects its performance and capability to connect with other devices. Diameter measuring machines, often equipped with laser or contact sensors, offer real-time data, ensuring that the specifications are adhered to during the manufacturing process.

3. Thickness Measuring Machines Insulation thickness is vital for safe and effective cable operation. Using non-destructive testing methods like ultrasonic thickness measurement, these machines verify the insulation's integrity without damaging the cable itself. This process not only assures quality but also helps in maintaining production throughput.

4. Electrical Testing Equipment Though primarily measuring machines focus on physical dimensions, electrical testing equipment also plays a role in ensuring the functional capabilities of the cables. High-voltage testers and continuity testers check for faults or weaknesses, ensuring that electrical properties meet the necessary standards for safe operation.

measure machine for cables exporters

5. Multi-parameter Measurement Systems Advanced technology has led to the development of multi-parameter measurement systems that can integrate various functions into a single machine. These systems can measure length, diameter, thickness, and other characteristics concurrently, revolutionizing the manufacturing workflow.

Enhancing Operational Efficiency

Investing in high-quality measuring machines can significantly enhance operational efficiency for cable exporters. Here’s how

- Quality Control Automated measuring machines facilitate consistent quality control. By minimizing human error, they ensure that every batch of cables produced adheres to quality standards, thereby reducing the risk of reworking or returns.

- Speed and Productivity In a competitive market, time is of the essence. High-speed measuring machines enable quick assessments, which boost production rates. This efficiency allows companies to meet deadlines and increases the overall output of the manufacturing facility.

- Cost Reduction With improved accuracy and efficiency, companies can reduce waste and minimize the costs associated with production errors. This results in significant savings that can be reinvested into the business for further growth.

- Market Compliance Different countries have distinct regulations regarding cable manufacturing and exportation. Measuring machines help exporters comply with these regulations, ensuring that products meet safety and quality standards set by international bodies.

Conclusion

In conclusion, measuring machines play an integral role in the cable export industry. By ensuring that cables meet precise specifications and quality standards, these machines not only uphold the reputation of exporters but also contribute to the safety and reliability of electrical systems worldwide. As technology continues to advance, embracing innovative measuring solutions will be crucial for cable exporters looking to thrive in a highly competitive global market. Investing in these machines is not merely an operational decision; it’s a strategic move that can determine the long-term success of a business.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy