Measuring Equipment Solutions for Cable Manufacturing Industry and Factories

Measuring Machines for Cable Factories Ensuring Precision and Quality

In today's fast-paced manufacturing environment, the production of cables is a critical aspect of various industries, including telecommunications, energy, and automotive. As the demand for high-quality cables increases, so does the need for precision measurement in cable factories. Measuring machines specifically designed for these environments play a crucial role in ensuring the quality and reliability of the end products.

Cable manufacturing involves a series of complex processes, including wire drawing, insulation, stranding, and assembly. Each of these stages requires exact measurements to ensure that the cables meet industry standards and customer specifications. For instance, the diameter of the wires must be consistent to maintain electrical properties and strength. Similarly, the thickness of insulation materials is vital for ensuring safety and performance. Any deviations in these measurements can result in defective products, leading to costly recalls and a tarnished reputation for manufacturers.

To address these challenges, cable factories are increasingly investing in advanced measuring machines. These machines provide accurate and real-time data, allowing manufacturers to monitor quality at every stage of production. Here are some key features and benefits of measuring machines used in cable manufacturing

1. Automated Precision Modern measuring machines utilize sophisticated technology such as laser measurement and optical sensors to ensure high precision. These methods allow for non-contact measurement, which reduces the risk of damage to the products and ensures that measurements are taken quickly and accurately.

2. Increased Efficiency Traditional measurement methods can be time-consuming and prone to human error. Automated measuring machines streamline the process, allowing operators to obtain measurements instantaneously. This efficiency not only speeds up production but also increases throughput, enabling factories to meet growing demands.

measure machine for cables factories

3. Comprehensive Data Collection Advanced measuring machines are equipped with data logging capabilities that allow manufacturers to collect and analyze extensive data over time. This information can be invaluable for identifying trends, conducting quality control, and making informed decisions regarding process improvements. With access to accurate historical data, manufacturers can also comply with regulatory requirements and maintain certifications.

4. Customization Different types of cables require different measurement specifications. Measuring machines can be customized to meet specific requirements, whether for electrical cables, fiber optics, or specialty cables. This versatility helps manufacturers adapt to changes in market demands and technological advancements.

5. User-Friendly Interfaces Many modern measuring machines come with intuitive interfaces, making them easy to operate for personnel with varying levels of technical expertise. This ease of use reduces training time and enhances productivity on the factory floor.

6. Real-Time Monitoring and Feedback Some measuring systems include features that allow for real-time monitoring of production quality. Instant feedback can alert operators to discrepancies as they occur, enabling immediate corrective actions to be taken. This proactive approach significantly minimizes defective outputs and reduces waste.

In conclusion, the importance of measuring machines in cable factories cannot be overstated. As the industry continues to evolve, the demand for high-quality, reliable cables will only grow. By investing in advanced measurement technologies, cable manufacturers can ensure that their products meet stringent quality standards, enhance their operational efficiency, and maintain a competitive edge in the market. As we move forward, the integration of measurement systems with Industry 4.0 technologies, such as IoT and AI, will further revolutionize cable manufacturing, leading to even more precise and efficient production processes. Embracing these advancements is key to achieving excellence in cable manufacturing.

-

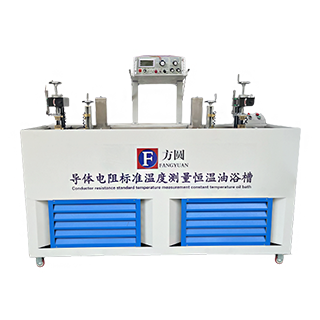

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy