Optimizing Cable Production with Advanced Measurement Technologies for Manufacturers

Measuring Machines for Cable Manufacturers Elevating Efficiency and Quality Control

In the fast-paced world of manufacturing, precision and reliability are paramount, particularly in industries where cables are integral to the operation of various technologies. The cable manufacturing sector has seen substantial advancements in measuring technologies, driving the need for sophisticated measurement machines that ensure quality, accuracy, and efficiency. These machines play a critical role in the production process, from raw material inspection to the final quality check before distribution.

The Importance of Measurement in Cable Manufacturing

Cables are essential components in numerous applications, from electrical wiring in residential buildings to complex aerospace systems. The safety and functionality of these systems depend heavily on the quality of the cables produced. Therefore, implementing rigorous measurement standards is essential. The use of measuring machines allows manufacturers to maintain strict quality control, ensuring that every cable meets industry standards and specifications.

Types of Measurement Machines

1. Dimensional Measurement Machines These machines are designed to assess the physical dimensions of cables, including diameter, length, and cross-sectional area. Advanced laser measurement systems and coordinate measuring machines (CMMs) are commonly used to achieve high precision. The benefits of dimensional measurement include minimized production errors, optimized material usage, and enhanced product reliability.

2. Electrical Testing Machines Given that cables are primarily used for electrical transmission, measuring machines that test electrical properties—such as resistance, capacitance, and insulation quality—are crucial. These machines help validate that cables meet necessary electrical standards, preventing failures that could result in costly damages or safety hazards.

3. Mechanical Testing Machines Cables must withstand various mechanical stresses during operation. Testing machines assess tensile strength, flexibility, and adhesion properties. Advanced testing methods, including dynamic fatigue testing and environmental resistance assessments, ensure that cables can endure real-world conditions.

4. Optical Measurement Systems Optical systems utilize advanced imaging technologies to detect surface defects, gauge material consistency, and analyze color variations. These machines are valuable in ensuring that aesthetic standards are met, in addition to functional integrity.

Benefits of Implementing Measuring Machines

measure machine for cables manufacturer

Investing in state-of-the-art measuring machines brings numerous advantages to cable manufacturers

- Increased Accuracy Automated measuring systems significantly reduce human error, providing accurate data that can be trusted.

- Improved Efficiency Streamlined measurement processes minimize the time spent on quality checks, allowing for faster production cycles. Manufacturers can meet tight delivery schedules while maintaining quality.

- Enhanced Regulatory Compliance With stringent industry regulations, measurement machines help manufacturers comply with international standards, such as ISO and IEC, thus avoiding costly penalties and fostering customer trust.

- Data-Driven Decision Making Modern measuring machines often come equipped with software that provides data analytics capabilities. This data can guide decision-making processes, enhancing production strategies and identifying areas for improvement.

Challenges and Future Directions

While the advantages of measuring machines are clear, there are challenges associated with their implementation. The initial investment can be substantial, and staff may require training to manage and operate these advanced systems effectively. Additionally, the rapid evolution of technology means that manufacturers must stay abreast of the latest advancements to remain competitive.

Looking forward, the integration of artificial intelligence (AI) and machine learning into measuring machines promises to revolutionize the field. These technologies can enhance predictive maintenance, automate data analysis, and further minimize errors, paving the way for the future of cable manufacturing.

Conclusion

In conclusion, the integration of measuring machines into cable manufacturing is not merely a trend but a necessary evolution in the pursuit of quality and efficiency. As manufacturers strive to meet the demands of a dynamic market, investing in advanced measurement technologies will enable them to produce reliable, high-quality cables that satisfy both regulatory standards and consumer expectations. By prioritizing precision and efficiency, the cable manufacturing industry can ensure its pivotal role in supporting the technological frameworks of tomorrow.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

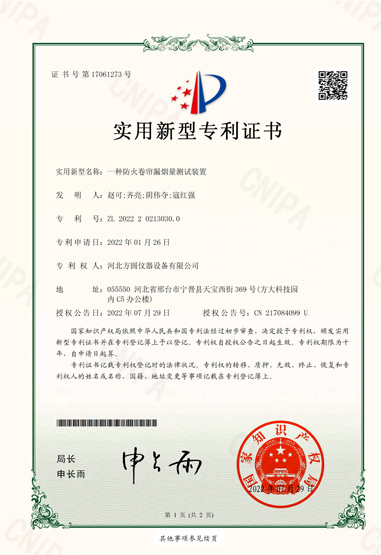

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy