measure machine for cables supplier

Measuring Machinery for Cable Suppliers A Vital Investment for Efficiency and Quality

In the ever-evolving landscape of the cable manufacturing industry, suppliers face increasing demands for precision, efficiency, and quality. As the market grows more competitive, the need for advanced measuring machinery has become indispensable. This investment not only enhances production capabilities but also ensures that manufacturers meet the stringent standards required by customers and regulatory bodies.

Measuring Machinery for Cable Suppliers A Vital Investment for Efficiency and Quality

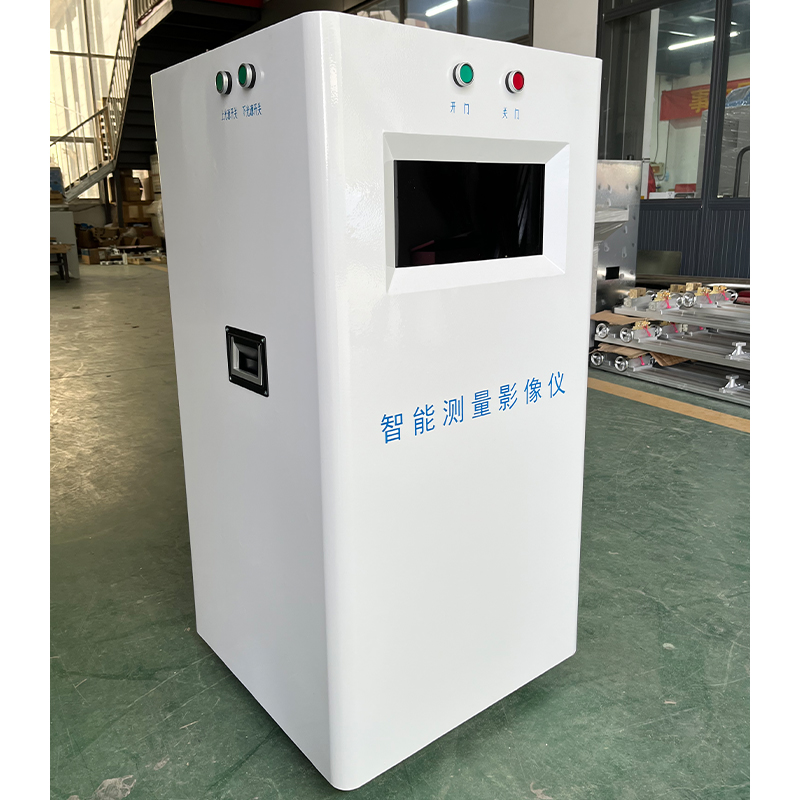

The use of advanced measuring technologies, such as laser measurement systems and automated vision inspection, allows suppliers to achieve unprecedented levels of accuracy. Laser systems can measure dimensions without contact, reducing the risk of damage to the product while providing instantaneous feedback. Meanwhile, automated vision systems can conduct comprehensive inspections, identifying defects that the human eye might miss, thus enhancing overall product quality.

measure machine for cables supplier

Moreover, these measuring machines can significantly improve operational efficiency. Traditional measurement methods can be time-consuming and prone to errors, often leading to production delays. In contrast, automated measuring systems streamline the inspection process, allowing for faster production cycles and reducing downtime. This efficiency not only maximizes throughput but also minimizes waste, ultimately contributing to a more sustainable production process.

Investment in high-quality measuring machinery also impacts the supplier's reputation. In a market where quality assurance is paramount, having state-of-the-art equipment signals to customers that a supplier is committed to excellence. This commitment can translate into customer loyalty, increased orders, and an improved market position. By consistently delivering high-quality products, suppliers can differentiate themselves from competitors, making them a preferred choice in a crowded market.

Furthermore, regulatory compliance is another critical aspect that measuring machines help address. Many industries, including automotive, aerospace, and construction, have stringent standards for cable products. Non-compliance can result in severe penalties and reputational damage. Advanced measuring equipment ensures that products not only meet client specifications but also adhere to industry regulations, safeguarding the supplier's market standing.

In conclusion, for cable suppliers looking to thrive in a competitive environment, investing in advanced measuring machinery is not just an option; it is a necessity. By enhancing precision, improving efficiency, and ensuring compliance, these machines play a crucial role in optimizing production and building a solid reputation. As the industry continues to grow, embracing cutting-edge measurement technologies will undoubtedly pave the way for future success.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy