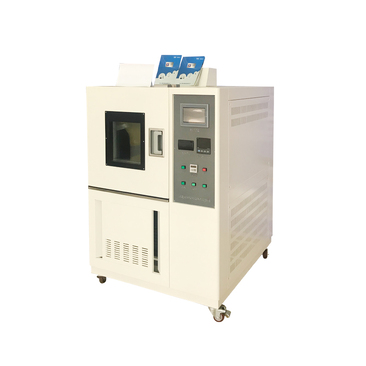

measure machine for cables supplier

Measuring Machines for Cable Suppliers A Comprehensive Overview

In today's industrial landscape, precision and efficiency are paramount, especially for cable suppliers who cater to a variety of sectors, including telecommunications, power distribution, and construction. The integrity of cables, whether they are for transmitting electrical signals or providing power, rests heavily on accurate measurements and quality assurance processes. Hence, measuring machines have emerged as indispensable tools in the operations of cable manufacturers and suppliers.

The Importance of Accurate Measurements

Accurate measurements are critical in the cable industry for several reasons. Firstly, they ensure compliance with stringent industry standards and regulations. Cables that do not meet the necessary specifications can lead to performance issues, electrical hazards, and substantial financial losses. Secondly, quality control processes that include meticulous measurements can help in the reduction of waste and rework, thereby improving overall operational efficiency.

Types of Measuring Machines

Cable suppliers utilize various measuring machines, each designed for specific tasks. Here are some of the most common types

1. Dimensional Measuring Machines (DMM) These machines measure the physical dimensions of cables, including diameter, length, and thickness. DMMs provide precise data that are vital for ensuring that the cables meet required specifications.

2. Electrical Testing Equipment This category includes devices that assess a cable's electrical properties, such as resistance, capacitance, and insulation levels. Insulation resistance testers and continuity testers are common examples that ensure cables perform as intended under operational conditions.

3. Laser Measurement Systems These advanced machines use laser technology to provide highly accurate measurements of cable dimensions. They are especially useful for long cables or when high precision is required.

measure machine for cables supplier

4. Optical Measurement Systems Utilizing camera systems and image processing, these devices can inspect cable surfaces for defects or inconsistencies. They help in identifying issues such as surface roughness, color uniformity, and other visual parameters.

Integration with Modern Technology

Recent advancements in technology have led to the integration of measuring machines with digital tools, enhancing their functionality. For instance, many cable suppliers now use software that allows for real-time data collection and analysis. This capability enables swift adjustments to manufacturing processes and immediate responses to quality control issues.

Moreover, the advent of Industry 4.0 has paved the way for smart manufacturing solutions. Measuring machines can now be connected to the Internet of Things (IoT), facilitating remote monitoring and updates. This connectivity ensures that suppliers can maintain high-quality standards without interrupting production.

The Role of Calibration

Calibration is vital for ensuring that measuring machines provide reliable results. Regular calibration of measuring equipment helps maintain accuracy over time and is crucial in fulfilling compliance obligations. Cable suppliers are therefore encouraged to set up stringent calibration protocols to sustain the precision of their measurement systems.

Conclusion

In conclusion, measuring machines play a pivotal role in the operations of cable suppliers. By ensuring accurate measurements, these machines help maintain compliance with industry standards, reduce waste, and enhance product quality. The integration of modern technology further amplifies their effectiveness, positioning cable suppliers to meet the increasing demands of a competitive market. As industries continue to evolve, investing in advanced measuring machines will remain a key strategy for cable suppliers seeking to uphold their reputation and deliver exceptional products to their customers.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy