Evaluating the Accuracy of Projectors Through Effective Measurement Techniques

Measuring Projector An Essential Tool for Precision in Manufacturing

In the world of manufacturing and engineering, precision is paramount. Quality control and accuracy in measurements can significantly impact the performance and reliability of products. One of the most essential tools in this pursuit of precision is the measuring projector, also known as a optical comparator. This device offers a unique and effective method for inspecting and measuring parts by projecting magnified images of the components onto a screen or surface, allowing operators to make precise measurements and assessments.

What is a Measuring Projector?

A measuring projector utilizes optics to project an enlarged shadow image of a workpiece onto a screen. This process allows operators to compare the dimensions of the workpiece against specified tolerances or geometric features. The fundamental concept behind this tool is to transform an object’s three-dimensional characteristics into a two-dimensional representation, which can be easily analyzed and measured.

Measuring projectors come in various sizes and configurations, but they generally feature a light source, a lens system, and a large projection screen. The light source illuminates the workpiece, typically placed on a glass stage, while the lens system magnifies the image and projects it onto the screen. Operators can then use calibrated measurement tools such as grids, scales, and overlays to take precise measurements.

Key Advantages of Measuring Projectors

1. High Accuracy One of the primary advantages of using a measuring projector is the precision it offers. With the ability to magnify images, operators can easily identify small features, allowing for accurate measurements down to micrometers.

2. Ease of Use Measuring projectors are relatively easy to use. The process only requires placing the part onto the stage, adjusting the focus, and magnifying the image. This simplicity makes it accessible even for operators with minimal training.

3. Fast Measurement Compared to traditional measurement techniques, measuring projectors provide quicker assessment results. The visual representation of the part allows for immediate identification of deviations or non-conformance with specifications.

4. Versatility These devices are suitable for a wide range of applications across various industries, including aerospace, automotive, and medical device manufacturing. They can inspect everything from intricate components to larger parts due to their adjustable configurations.

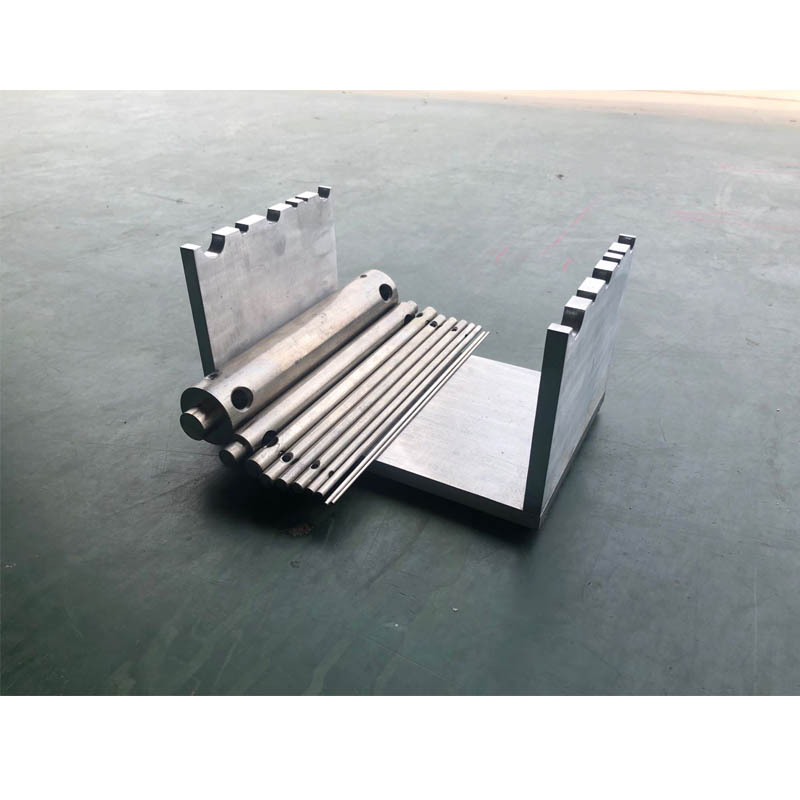

measuring projector

5. Reduced Human Error By providing a visual reference, measuring projectors help minimize human error in measurements. Operators can directly observe discrepancies and inaccuracies during inspection, leading to more reliable outcomes.

6. Real-Time Feedback The nearly instantaneous feedback allows for rapid adjustments in the manufacturing process, promoting efficiency and reducing waste. If a part does not meet the required specifications, immediate corrective measures can be taken.

Applications of Measuring Projectors

Measuring projectors are widely used in various applications, including

- Quality Control They serve as a crucial tool in quality control processes, ensuring that manufactured parts meet specified tolerances and dimensional requirements. - Tool and Die Inspection Measuring projectors are essential in the tool and die industry, where precision is critical. They help validate the dimensions of molds, dies, and other tooling components.

- Prototype Testing When developing prototypes, measuring projectors can assist in assessing accuracy and fidelity to design specifications. Early detection of errors can save time and resources during the development phase.

- Engineering Analysis Engineers often utilize measuring projectors for technical analyses, allowing for detailed evaluations of part geometry and functionality.

Conclusion

In conclusion, the measuring projector is an invaluable tool in the realm of precision manufacturing. Its ability to provide accurate, efficient, and user-friendly measurements makes it indispensable for quality control and product development. As industries continue to evolve and seek higher standards of quality and accuracy, the measuring projector will undoubtedly remain a cornerstone of precision measurement technology, facilitating innovative manufacturing processes and ensuring that products meet rigorous standards. Embracing this technology is essential for any company aiming to maintain a competitive edge in today’s dynamic market.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy