mechanical tensile tester manufacturers

When it comes to material testing, the mechanical tensile tester plays a pivotal role in evaluating the strength and ductility of various materials. Widely used in industries such as construction, automotive, aerospace, and manufacturing, tensile testers are essential tools for determining how materials behave under tension.

Mechanical tensile testers are designed to apply a controlled load to a material specimen, measuring its response until failure occurs. This process helps manufacturers understand the material's properties, such as yield strength, ultimate tensile strength, elongation, and modulus of elasticity. These properties are crucial for quality control, research and development, and compliance with industry standards.

As the demand for high-quality materials increases, the need for reliable tensile testing equipment has surged. Numerous manufacturers have emerged in the market, each offering a range of mechanical tensile testers tailored to meet specific testing requirements. Leading manufacturers invest heavily in research and development to enhance the precision and durability of their machines, ensuring that they can accommodate various types of materials, including metals, polymers, and composites.

When selecting a mechanical tensile tester, it's essential to consider several factors. First, the machine's capacity should match the specific materials you intend to test. Additionally, the testing speed and the method of load application—whether static or dynamic—should align with your testing protocols. Advanced models may come equipped with software that facilitates data analysis and reporting, providing valuable insights into material performance.

mechanical tensile tester manufacturers

Among the prominent mechanical tensile tester manufacturers, some are renowned for their innovative designs and robust customer support. Brands like Instron, ZwickRoell, and MTS Systems are key players in the industry, known for their commitment to quality and accuracy. These companies offer a variety of models ranging from basic testers for educational purposes to sophisticated systems capable of testing high-strength materials.

Furthermore, with the advent of technology, modern tensile testers are increasingly equipped with features such as digital displays, automatic grips, and real-time data collection. These enhancements improve user experience and ensure that accurate measurements are obtained efficiently.

In conclusion, mechanical tensile testers are invaluable assets for any organization involved in material production and testing. The choice of a manufacturer can significantly impact testing results, making it crucial for companies to partner with reputable suppliers that provide reliable equipment and support. As industries continue to evolve, the role of mechanical tensile testing will remain vital in ensuring the integrity and performance of materials used in various applications.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

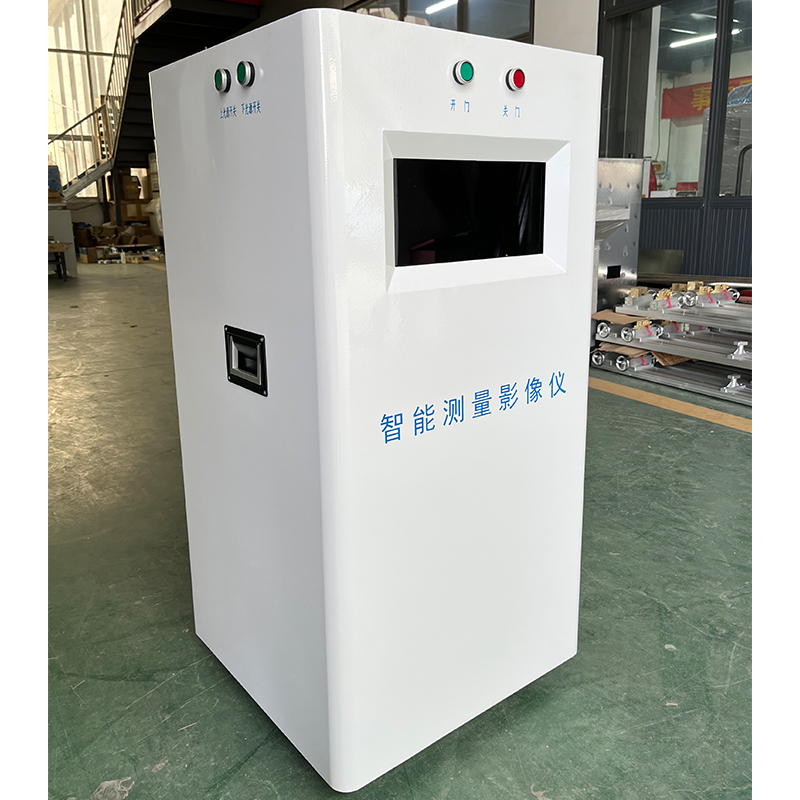

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy