mechanical tensile tester manufacturers

Understanding Mechanical Tensile Tester Manufacturers

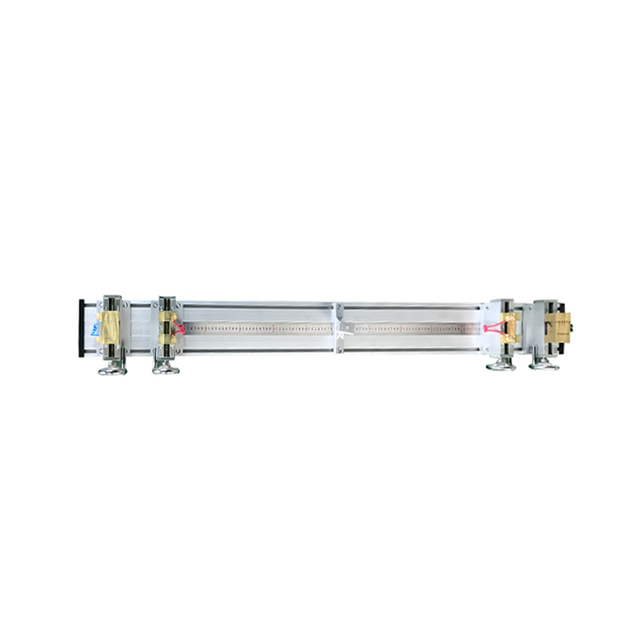

Mechanical tensile testers play a crucial role in materials testing, providing vital data for quality control, product development, and research. These devices measure the resistance of materials when subjected to tension, assessing properties such as tensile strength, elongation, and modulus of elasticity. The manufacturers of mechanical tensile testers are key players in the materials testing industry, delivering innovation, precision, and reliability to meet the evolving needs of diverse sectors.

The Importance of Mechanical Tensile Testing

In industries ranging from aerospace to construction, understanding a material’s behavior under stress is essential. Mechanical tensile testers help engineers and researchers evaluate how materials react to applied forces, ensuring that they meet safety and performance standards. These tests are particularly significant in quality assurance processes, where the durability and usability of materials can greatly impact final products. For example, manufacturers of automotive components need assurance that their materials can withstand dynamic loads over time without failure, while textile manufacturers must ensure their products can endure stretching and wear.

Key Features of Mechanical Tensile Testers

When selecting a mechanical tensile tester, several features should be considered

1. Load Capacity Depending on the materials being tested, tensile testers come in various load capacities, which can range from a few Newtons for lightweight materials to several thousand Newtons for robust industrial applications.

2. Test Speed Adjustable test speeds allow manufacturers to simulate real-life conditions accurately, enabling data generation that mirrors actual product usage.

3. Data Acquisition and Analysis Modern tensile testers often include advanced software that facilitates data collection and analysis. This can include stress-strain curves, which provide insights into the material’s characteristics.

4. User-Friendly Interface Ease of use and accessibility are crucial, especially in high-volume testing environments. Intuitive interfaces reduce training time and increase overall operational efficiency.

mechanical tensile tester manufacturers

5. Compliance with Standards Manufacturers ensure their tensile testers comply with international testing standards like ASTM, ISO, and EN. Adherence to these standards guarantees that test results are valid and comparable across different labs and industries.

Leading Manufacturers in the Industry

The market for mechanical tensile testers features several prominent manufacturers known for their quality, innovation, and reliability. Companies such as Instron, MTS Systems Corporation, and Zwick Roell have established their reputation by consistently delivering high-performance equipment tailored to various industries.

1. Instron With a history dating back to the 1940s, Instron is a leading name in materials testing technology. Their comprehensive range of tensile testers is known for precision and is widely used in research and industrial applications alike.

2. MTS Systems Corporation MTS has developed a range of testing solutions focusing on high-performance and high-throughput environments. Their equipment is favored in complex applications such as fatigue testing, dynamic mechanical analysis, and material characterization.

3. Zwick Roell This German manufacturer focuses on quality management and has tailored its tensile testing systems for a variety of applications, highlighting its commitment to customer satisfaction and technological advancement.

The Future of Mechanical Tensile Testing

As technology evolves, mechanical tensile testers are becoming increasingly sophisticated. Advancements in automation, digital data management, and artificial intelligence are shaping the future of materials testing. These technologies enhance accuracy, reduce operational costs, and improve data handling and interpretation. Manufacturers are also expanding their offerings to include multi-function machines that can perform various tests, providing greater flexibility for testing laboratories.

Conclusion

Mechanical tensile testers are an indispensable part of the material testing landscape, with manufacturers playing a pivotal role in ensuring high-quality testing solutions. As industries demand more advanced materials capable of meeting rigorous standards, these manufacturers must continue to innovate and adapt to changing market needs. By investing in reliable and efficient tensile testing equipment, companies can guarantee the performance and safety of their products, ultimately leading to more successful outcomes in their respective fields. The future of mechanical tensile testing is bright, with endless possibilities for innovation and improvement on the horizon.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy