Reliable Suppliers of Mechanical Tensile Testing Equipment for Quality Assurance Solutions

Choosing the Right Mechanical Tensile Tester Supplier for Your Needs

In the world of materials testing, mechanical tensile testers play a crucial role in determining the physical properties of materials under tension. Whether in construction, manufacturing, or research labs, the accurate measurement of tensile strength, yield strength, elongation, and other essential metrics is vital for ensuring that materials meet the required specifications and standards. As industries continue to grow, so does the demand for reliable and high-quality tensile testing equipment. Thus, selecting the right mechanical tensile tester supplier becomes a critical decision for any organization involved in materials testing.

Understanding Mechanical Tensile Testers

A mechanical tensile tester is a device designed to apply a controlled amount of force to a material specimen until it deforms or breaks. This equipment typically includes a loading frame, grips, and a measurement system to analyze the specimen's response to the applied load. The data obtained from these tests helps engineers and manufacturers understand how materials will perform in real-life applications. There's a wide range of testers available, from basic models suitable for educational purposes to advanced systems equipped with sophisticated software for comprehensive data analysis.

Importance of Choosing the Right Supplier

When it comes to selecting a mechanical tensile tester supplier, various factors need to be considered. The supplier's reputation is a primary consideration. A reputable supplier will be known for providing reliable equipment that meets industry standards and will stand behind their products with robust customer support and warranties.

Additionally, the specific needs of your testing applications should guide your supplier choice. Different industries may require different specifications in tensile testing equipment. For example, if you are testing metals, you will require a different tensile tester compared to one used for plastics. Suppliers with a diverse product range can help pinpoint the right machine.

Considerations for Supplier Evaluation

mechanical tensile tester supplier

1. Product Range Evaluate whether the supplier offers a wide range of tensile testing machines that cater to diverse materials and testing standards. This flexibility can be beneficial as your testing needs evolve.

2. Quality Assurance Ensure that the supplier adheres to stringent quality control measures. Look for equipment that complies with international testing standards such as ASTM, ISO, or EN standards for assurance of quality and accuracy.

3. Technical Support Robust technical support is essential, particularly for organizations new to tensile testing. Ensure that the supplier offers training, installation services, and ongoing support to help you leverage the capabilities of the equipment effectively.

4. Customization Options Some projects may require specialized testing setups. A supplier that offers customized solutions can meet specific needs that standard models may not address.

5. User Reviews Research user experiences and reviews regarding the supplier's equipment performance and customer service. Forums and industry publications can provide valuable insights.

6. Price and Warranty While budget constraints are crucial, opting for the cheapest option may not always yield the best results. Assess the value provided for the price, including warranty terms. A longer warranty can provide greater peace of mind and protect your investment.

Conclusion

Selecting the right mechanical tensile tester supplier is not merely about procuring a piece of equipment; it is a strategic decision that can impact the quality of your materials testing and overall product development. As industries continue to innovate, reliability in testing processes becomes paramount. By thoroughly evaluating suppliers based on quality, support, and product offerings, organizations can ensure they are equipped with the right tools to drive success in their respective fields. Investing in a reliable tensile testing solution will not only enhance testing accuracy but also contribute to the development of safer and higher-quality materials.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

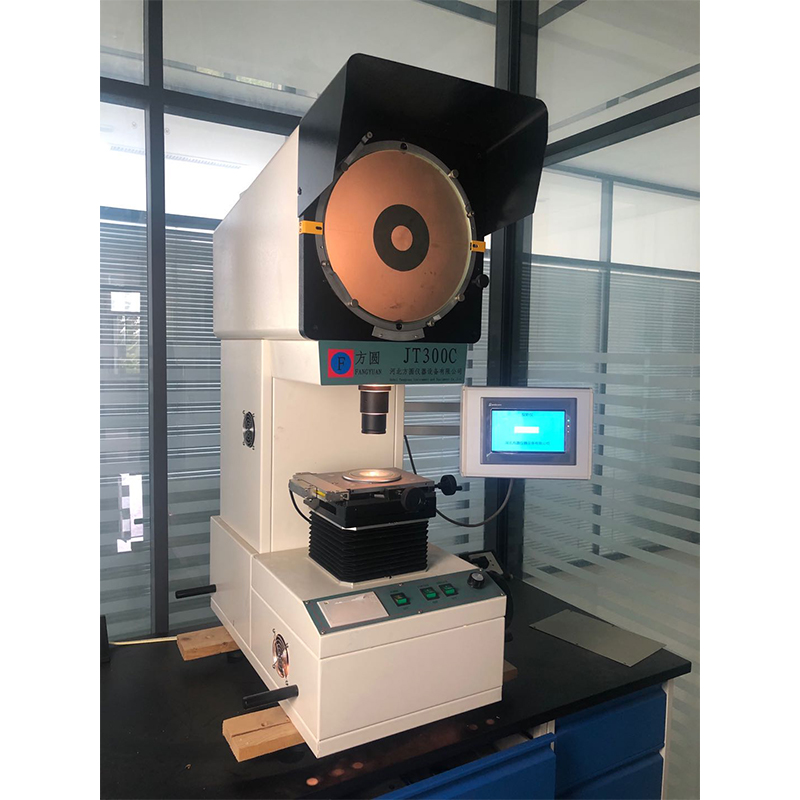

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy