Optical Coordinate Measuring Machine Factory - Precision Measurement Solutions

The Role of Optical Coordinate Measuring Machines in Modern Manufacturing

In the evolving landscape of modern manufacturing, precision and accuracy have become paramount. Optical coordinate measuring machines (CMMs) stand at the forefront of this technological revolution, bridging the gap between traditional measurement techniques and advanced optical solutions. These sophisticated devices play a crucial role in ensuring the quality and conformity of manufactured products.

Optical CMMs utilize advanced optical technologies to measure and analyze the geometry of physical objects. Unlike conventional mechanical CMMs that often rely on contact probes, optical CMMs employ non-contact measurement systems, such as laser and camera systems. This capability allows for high-speed measurements with minimal risk of damaging delicate surfaces or small components. As industries increasingly deal with intricate designs and miniaturized parts, optical CMMs have become indispensable tools in quality assurance processes.

One of the defining features of optical CMMs is their exceptional accuracy. They are capable of measuring various parameters, including length, width, height, and angles, with a precision that surpasses many traditional methods. The integration of software that processes measurement data further enhances accuracy, enabling manufacturers to identify deviations from standard specifications promptly. This real-time feedback loop is invaluable in preventing defects early in the production line, leading to reduced waste and heightened productivity.

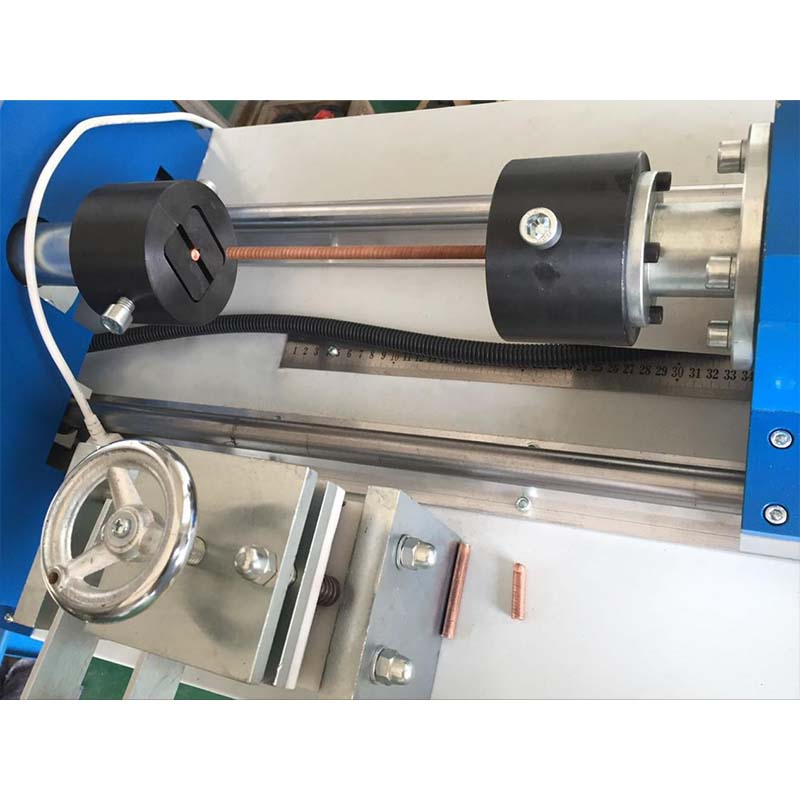

optical coordinate measuring machine factory

Another significant advantage of optical CMMs is their versatility. They can be used to measure a wide range of materials, from metals and plastics to ceramics and glass. This adaptability makes them suitable for diverse applications across different sectors, including aerospace, automotive, electronics, and medical device manufacturing. As companies strive to streamline their operations and improve quality control, the functionality offered by optical CMMs becomes increasingly attractive.

Moreover, the integration of optical coordinate measuring technology with automation and robotics is a game-changer for the manufacturing industry. Automated optical CMMs can rapidly conduct inspections without human intervention, resulting in faster turnaround times. As part of a fully automated production environment, they provide continuous quality monitoring, ensuring that each component consistently meets stringent quality standards.

In conclusion, optical coordinate measuring machines are transforming the way manufacturers approach quality control and measurements. Their non-contact measurement capabilities, high accuracy, versatility, and compatibility with automation make them essential tools in today’s competitive manufacturing landscape. As industries continue to innovate and push the boundaries of technology, optical CMMs will undoubtedly play a pivotal role in ensuring that quality and precision remain at the forefront of production processes. The factory of the future is increasingly reliant on such advanced technologies, and optical CMMs are leading the charge in this new era of manufacturing excellence.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy