optical measurement instruments manufacturer

The Importance of Optical Measurement Instruments in Modern Industries

Optical measurement instruments are vital tools in many industries, providing precise and reliable data necessary for quality control, research, and development. These instruments utilize the properties of light to measure various parameters, such as distance, thickness, and surface profile, ensuring that products meet stringent specifications.

Manufacturers of optical measurement instruments have significantly advanced technology over the years, leading to the development of sophisticated tools tailored to meet the needs of various sectors. These instruments are crucial in industries such as aerospace, automotive, electronics, and biomedical, where accuracy is paramount. For instance, in the aerospace industry, optical measurement tools are used to inspect components with intricate geometries and to ensure that they meet safety and performance standards.

One of the most common types of optical measurement instruments is the laser interferometer. This tool leverages the coherence of laser light to measure small distances with exceptional precision. Laser interferometers play a vital role in the calibration of machine tools and other manufacturing equipment, allowing companies to maintain high levels of accuracy and quality in their production processes.

Another important category of optical measurement instruments includes optical microscopes and scanning probe microscopes. These tools enable manufacturers to inspect surfaces at the microscopic level, revealing defects that may not be visible to the naked eye. This capability is essential in the semiconductor industry, where even the slightest imperfections can lead to significant failures in electronic devices.

optical measurement instruments manufacturer

Moreover, advancements in imaging technology, such as high-resolution cameras and advanced software algorithms, have enhanced the functionality of optical measurement systems. These innovations allow for real-time monitoring and analysis, making it easier for manufacturers to detect problems early in the production process. By identifying defects sooner, companies can reduce waste, increase efficiency, and significantly lower production costs.

In recent years, the integration of artificial intelligence (AI) into optical measurement technology has further revolutionized the industry. AI-powered systems can analyze vast amounts of data quickly, identifying trends and anomalies that may not be immediately apparent to human operators. This capability enhances decision-making processes, allowing manufacturers to optimize their operations more effectively.

As industries continue to evolve, the demand for high-precision optical measurement instruments will only grow. Manufacturers that invest in cutting-edge optical technologies will be better positioned to meet the challenges of modern production environments. By ensuring product quality and operational efficiency, these instruments play a crucial role in helping businesses remain competitive in an ever-changing market.

In conclusion, optical measurement instruments are indispensable in today’s manufacturing landscape. Their ability to provide accurate and reliable measurements empowers industries to maintain high standards of quality, drive innovation, and improve productivity. As technology advances, so too will the capabilities of these instruments, further solidifying their role as essential tools for manufacturers worldwide.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

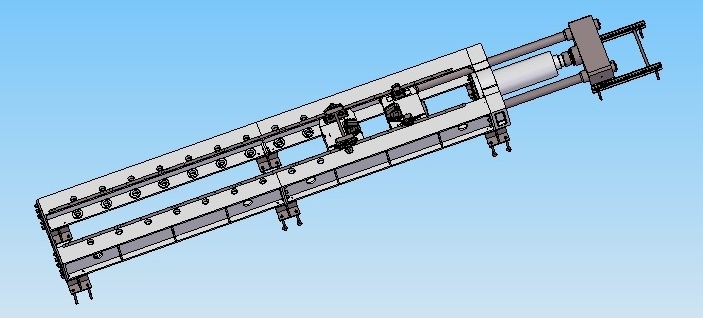

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy