Manufacturer of Precision Optical Measurement Instruments for Enhanced Accuracy and Performance

The Role of Optical Measuring Instrument Manufacturers in Precision Measurement

In the dynamic landscape of modern manufacturing and quality control, optical measuring instrument manufacturers play a pivotal role. These companies specialize in the design, development, and production of advanced optical measurement technologies that are critical for ensuring precision and accuracy across various industries. From aerospace and automotive to pharmaceuticals and textiles, optical measuring instruments are indispensable tools that aid in maintaining quality standards and enhancing productivity.

Optical measuring instruments harness the principles of light to measure physical quantities with high precision. These instruments include a wide range of devices such as laser scanners, optical comparators, and coordinate measuring machines (CMMs) that utilize light-based measurements. One of the key advantages of optical measurement technologies is their non-contact nature, which minimizes the risk of damaging delicate components or interfering with the manufacturing process.

Key Technologies in Optical Measurement

Manufacturers in this sector utilize a variety of technologies to create sophisticated measuring instruments. Laser measurement technology, for instance, is widely employed for its unparalleled accuracy and speed. By using laser beams to measure distances and angles, these instruments are capable of achieving micrometer-level precision, making them ideal for quality control in intricate manufacturing processes.

Another significant technology is the use of image processing in optical measurement. High-resolution cameras analyze the images of components and compare them to predefined standards. This process is instrumental in identifying defects and ensuring that each part meets the requisite specifications. The ability to automate these inspections through sophisticated software further enhances the efficiency and reliability of the quality control processes.

The Importance of Calibration

Calibration is crucial in the realm of optical measurement. Manufacturers must ensure that their instruments provide accurate readings over time, which requires regular calibration against known standards. This not only maintains the integrity of measurements but also builds trust with clients who rely on these instruments for critical applications. Optical measuring instrument manufacturers often provide calibration services to their customers, ensuring instruments remain in peak operating condition.

optical measuring instrument manufacturer

Driving Innovation Through Research and Development

The field of optical measurement is continuously evolving, driven by advancements in technology and the demand for higher precision. Manufacturers invest significantly in research and development (R&D) to stay competitive and meet the changing needs of their customers. Innovations such as 3D optical measurement techniques and the integration of artificial intelligence (AI) into measurement systems are some of the trends shaping the future. AI can enhance image recognition capabilities, enabling faster and more accurate inspections while reducing human error.

Moreover, as industries adopt Industry 4.0 principles, optical measuring instruments are increasingly being integrated into smart manufacturing systems. This integration allows for real-time monitoring and data analysis, providing manufacturers with valuable insights into production processes and product quality.

The Future of Optical Measuring Instruments

Looking ahead, the future of optical measuring instrument manufacturers is bright, marked by several trends and opportunities. With the rapid advancement of technology, there is a growing market for portable and versatile optical measuring devices that can be used in various environments. Additionally, the rise of e-commerce and the need for rigorous quality assurance in online product deliveries present new challenges and opportunities for optical measurement technologies.

Furthermore, sustainability concerns are influencing manufacturing practices, leading to a demand for instruments that not only ensure quality but also promote eco-friendly practices. Manufacturers are responding by developing energy-efficient devices and exploring materials and processes that reduce environmental impact.

Conclusion

In conclusion, optical measuring instrument manufacturers are an essential component of the quality assurance landscape across multiple industries. Their innovations in measurement technology not only enhance precision but also drive efficiency and sustainability in manufacturing processes. As technology continues to advance, these manufacturers will play a vital role in shaping the future of measurement and quality control, ensuring that industries can meet the challenges and demands of a rapidly changing world. Whether through laser technology, image processing, or cutting-edge AI systems, the impact of optical measuring instrument manufacturers is profound and far-reaching.

-

The Role of Tensile Force Testers in Quality Control and Material Science

NewsAug.01,2025

-

Maintenance and Safety Tips for Aging Ovens

NewsAug.01,2025

-

Density Balance in Forensic Science

NewsAug.01,2025

-

Advanced Optical Measurement Technologies

NewsAug.01,2025

-

A Buyer’s Guide to Tensile Test Machines

NewsAug.01,2025

-

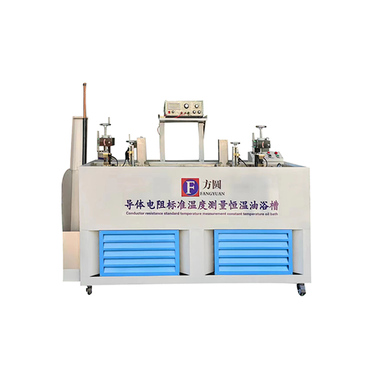

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy