optical measuring machines factories

The Evolution and Importance of Optical Measuring Machines in Modern Factories

In today’s fast-paced manufacturing landscape, precision, accuracy, and efficiency are paramount. One of the key technologies driving these elements forward is optical measuring machines (OMMs). These sophisticated devices utilize advanced optical techniques to measure the dimensions and characteristics of components with incredible precision, making them indispensable in modern factories.

The Evolution and Importance of Optical Measuring Machines in Modern Factories

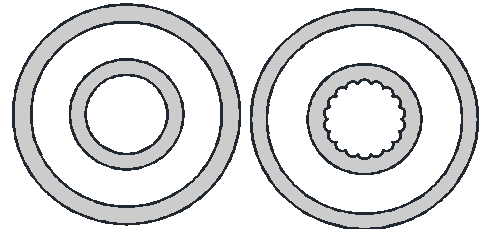

The design and components of optical measuring machines have evolved significantly over the years. Early models relied upon basic optical principles, utilizing manual positioning and simple lenses for measurement. However, advancements in technology have paved the way for automated systems that integrate computer numerical control (CNC) with high-resolution cameras and sophisticated software algorithms. These modern OMMs can now perform complex measurements in three dimensions, analyze surface imperfections, and provide instantaneous feedback to operators.

optical measuring machines factories

The integration of optical measuring machines into factory environments enhances productivity in several ways. First, the high-speed measurement capabilities allow manufacturers to reduce cycle times, enabling rapid prototyping and faster production lines. Secondly, the accuracy of OMMs minimizes the risk of defective parts reaching consumers. Manufacturing defects can lead to costly recalls and damage to a brand's reputation, making quality assurance a crucial pillar of the manufacturing process.

Moreover, optical measuring machines can collect vast amounts of data throughout the manufacturing process. This data can be leveraged to enhance operational efficiencies and refine production techniques. In a world increasingly driven by big data, manufacturers equipped with OMM technology can monitor trends, predict potential failures, and optimize their workflows based on real-time analytics. The synergy of measurement technology and data analysis substantiates a proactive approach to quality control, ultimately driving down costs and enhancing competitiveness.

Another significant advantage of OMMs is their versatility. These machines can be utilized in various applications, from measuring small components in electronics to assessing large parts in heavy machinery. Different industries have tailored optical measuring machines to meet specific requirements, such as increased measuring ranges or specialized software packages dedicated to particular measurement tasks. This adaptability ensures that OMMs find their place in a wide range of manufacturing environments.

In conclusion, the significance of optical measuring machines in factories cannot be overstated. As industries strive for higher accuracy, greater efficiency, and better product quality, OMMs stand out as critical tools capable of meeting these demands. The continued evolution of this technology, along with the integration of automation and data analytics, promises to further enhance their capabilities and applications. As manufacturers look to the future, investing in optical measuring machines will undoubtedly play a crucial role in maintaining competitiveness and achieving excellence in quality manufacturing.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy