optical profile projector factory

The Optical Profile Projector A Vital Tool in Precision Manufacturing

In the realm of precision manufacturing and quality control, the optical profile projector stands out as an indispensable instrument. This highly specialized equipment enables manufacturers to ensure that components meet stringent specifications and standards. Whether in the aerospace, automotive, or medical device industries, the accuracy provided by optical profile projectors is crucial for maintaining product integrity and safety.

The optical profile projector works by utilizing an optical lens system that magnifies the silhouette of a part onto a screen. With a light source projecting a clear image of the object, engineers can examine the contours and dimensions, making it easier to detect any deviations from the desired specifications. This process plays a vital role in inspections, allowing for real-time adjustments and ensuring that components fit seamlessly into larger assemblies.

The Optical Profile Projector A Vital Tool in Precision Manufacturing

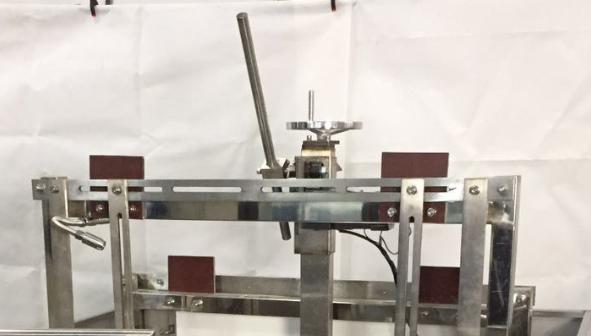

Factories specializing in the production of optical profile projectors prioritize precision and manufacturing excellence. These factories not only produce the machines themselves but also focus on the integration of advanced technologies such as digital readouts and image analysis software. This evolution has allowed for increased automation and enhanced data collection, further streamlining the quality control process.

optical profile projector factory

The assembly of an optical profile projector is a meticulous process. Each component, from the lens system to the projection mechanism, must be crafted with precision to ensure optimal performance. Manufacturers pay great attention to the calibration of these machines, as even minor discrepancies in alignment can result in inaccurate measurements. A dedicated team of engineers and quality assurance professionals typically oversees the production process to maintain the highest standards.

In addition to precision and reliability, modern optical profile projectors come equipped with user-friendly interfaces. This ease of use encourages operators at all skill levels to utilize the technology effectively. The transition from traditional measurement techniques to optical projection not only increases accuracy but also enhances throughput, ultimately benefiting production timelines and cost efficiency.

As industries evolve and the demand for high-precision components continues to grow, optical profile projectors will remain at the forefront of quality assurance processes. Factories committed to producing these machines are driven by the pursuit of excellence, ensuring that manufacturers can deliver products that meet and exceed customer expectations.

In conclusion, the optical profile projector is a vital tool in today’s manufacturing landscape. Its ability to deliver precision measurements and support complex inspections makes it an essential asset for quality control. As technology advances and factories continue to innovate, the role of the optical profile projector will only become more significant in ensuring the integrity and reliability of manufactured components.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy