Overview of PJ A3010 Profile Projector and Its Applications in Precision Measurement

Exploring the PJ-A3010 Profile Projector Precision in Measurement

In the world of precision engineering and manufacturing, accurate measurement is the cornerstone of quality control and product development. The PJ-A3010 profile projector emerges as a pivotal tool in achieving high standards of precision in various industries. Designed for ease of use, reliability, and efficiency, the PJ-A3010 stands out as a valuable asset for quality assurance and measurement tasks.

What is the PJ-A3010 Profile Projector?

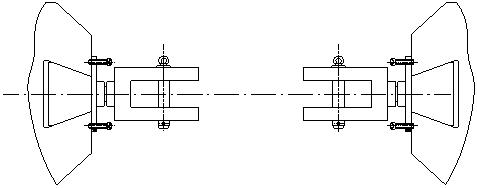

The PJ-A3010 profile projector is an optical measuring instrument that projects the silhouette of an object onto a screen, allowing for detailed analysis and measurement of its dimensions. This device is particularly beneficial for inspecting complex shapes and designs that would be difficult to measure with conventional tools. The projector employs a powerful lens system to illuminate the object with a bright light source, rendering a clear, magnified image that users can measure precisely.

Key Features and Specifications

The PJ-A3010 is characterized by several features that enhance its functionality and accuracy. With a robust and sturdy build, it ensures stability during operations, which is crucial for precision measurements. The optical system typically boasts a magnification range that accommodates various component sizes, allowing for flexibility in measurement tasks.

Another significant attribute of the PJ-A3010 is its resolution capability. High-resolution optics ensure that even the minutest details are visible, making it easier for operators to detect flaws or deviations from specifications. The device often includes a calibrated scale and can be equipped with digital readouts for quick and accurate data capture.

Applications of the PJ-A3010 Profile Projector

The versatility of the PJ-A3010 is evident in its wide range of applications across different sectors. In manufacturing, it is extensively used for quality control of machined parts, ensuring that components adhere to strict tolerances. Its applications span industries such as automotive, aerospace, medical devices, and electronics.

pj a3010 profile projector company

In the automotive industry, for instance, the PJ-A3010 can be used to measure intricate shapes of engine components and body parts. Similarly, in aerospace, it plays a crucial role in validating the precision of parts that are critical for safety and performance.

Moreover, the PJ-A3010 profile projector is invaluable in research and development (R&D) laboratories. Engineers and designers use this tool to analyze prototypes, comparing their dimensions against design specifications and making necessary adjustments in the design process.

Benefits of Using the PJ-A3010

The adoption of the PJ-A3010 profile projector brings numerous benefits to manufacturers and quality assurance professionals. First and foremost, its accuracy reduces the likelihood of defects in production, thereby saving time and costs associated with rework and failures.

Furthermore, the PJ-A3010 enhances efficiency in measurement processes. The ability to quickly project and measure components allows for faster turnaround times on inspections, which is critical in industries that operate on tight schedules and high demand.

In addition, the PJ-A3010 is user-friendly, with intuitive controls and a design that minimizes the learning curve for new operators. This ease of use encourages widespread adoption within teams and enhances overall productivity.

Conclusion

In conclusion, the PJ-A3010 profile projector represents a significant advancement in measurement technology. With its ability to provide precise and reliable measurements, it plays an essential role in ensuring quality and efficiency across various industries. As companies strive for greater accuracy and reduced production times, tools like the PJ-A3010 will continue to be integral to their operations, enabling them to meet the demands of today's competitive market. Investing in such technology not only improves product quality but also enhances customer satisfaction and business reputation.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy