power frequency spark tester exporters

Understanding Power Frequency Spark Testers and Their Export Dynamics

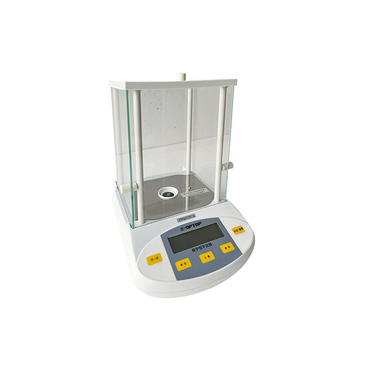

Power frequency spark testers play a crucial role in the electrical testing and quality assurance domains, specifically designed to assess the insulation strength of electrical equipment. As industries increasingly focus on ensuring the reliability and safety of electrical components, the demand for these testers has seen a notable rise. This article delves into the operational principles of power frequency spark testers, their applications, and the dynamics of their exporters in the global market.

What is a Power Frequency Spark Tester?

Power frequency spark testers generate high-voltage AC at standard power frequencies, typically around 50 or 60 Hz. This high voltage is applied to insulation materials to check their integrity. The testing method essentially involves subjecting a specimen to a voltage that is significantly higher than its operational voltage, allowing for the detection of weaknesses, defects, or potential breakdowns in the insulation.

The fundamental principle behind the operation of a spark tester is the creation of an electric field that penetrates the insulating material, causing a stress test. If the insulation is sound, it will withstand the applied voltage without any breakdown. Conversely, if there are faults, the insulation will fail, indicating areas that may need repair or replacement.

Applications of Power Frequency Spark Testers

Power frequency spark testers find extensive applications across various sectors, including

1. Manufacturing In factories that produce electrical components such as transformers, cables, and insulators, power frequency spark testers are essential for quality control. They ensure that the products meet safety standards before reaching the market.

3. Research and Development In R&D environments, these testers enable the evaluation of new materials and designs, helping engineers to innovate and test newer electrical technologies while ensuring safety and reliability.

power frequency spark tester exporters

4. Maintenance and Troubleshooting Existing electrical installations can be periodically checked using spark testers to preemptively identify insulation degradation, thus mitigating risks associated with electrical failures.

Export Dynamics of Power Frequency Spark Testers

The global market for power frequency spark testers has been buoyed by the increasing demand for electrical safety testing. Exporters of these devices face both opportunities and challenges. On the one hand, as countries develop their energy infrastructure, the demand for reliable testing equipment rises. Emerging economies are investing heavily in electrical utilities, providing exporters with a fertile ground for growth.

However, exporters must navigate a landscape of stringent regulations and certification requirements in different countries. Compliance with international safety standards—such as IEC and ISO— is critical for accessing various markets. Additionally, exporters must adapt to evolving technologies and remain competitive by investing in research and development to enhance product functionality and reliability.

Future Trends in the Spark Tester Market

Looking ahead, the market for power frequency spark testers is poised for growth driven by technological advancements. The integration of digital technologies and IoT into electrical testing is transforming how these devices operate. Smart testers that can collect and transmit data in real-time are becoming increasingly popular, providing users with enhanced insights and control.

Furthermore, as sustainability becomes a growing concern across industries, there is a push toward more energy-efficient testing devices. Exporters who focus on developing environmentally friendly technologies stand to gain a competitive edge in the burgeoning market.

Conclusion

Power frequency spark testers are invaluable tools in ensuring the safety and reliability of electrical components across various industries. Their significance in quality assurance cannot be overstated. As the global market continues to evolve, exporters must remain agile to adapt to regulatory changes, technological advancements, and growing market demands. By leveraging innovation and adhering to safety standards, the future of power frequency spark testers looks promising in a world increasingly reliant on electricity.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy