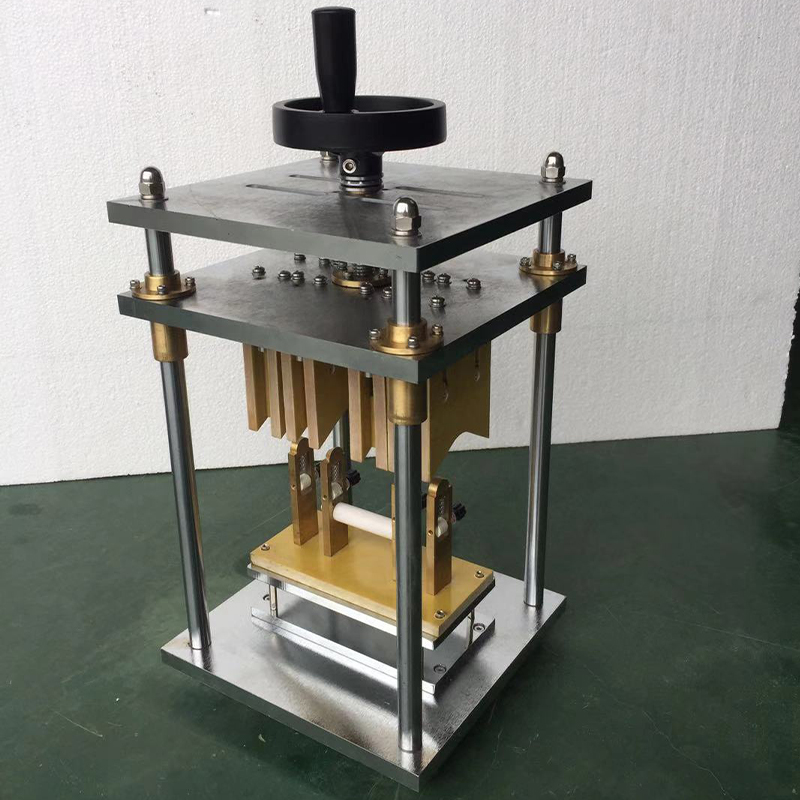

power frequency spark test machine

Understanding Power Frequency Spark Test Machines

Power frequency spark test machines are crucial instruments used in the electrical testing and maintenance of high-voltage equipment. These machines simulate high-voltage conditions to ensure the safety and reliability of electrical devices, from transformers to insulating materials. Understanding the operational principles, applications, and significance of these machines is vital for professionals in the electrical engineering field.

The Basics of Power Frequency Testing

Power frequency testing typically involves applying alternating current (AC) voltage at the standard frequency of 50 or 60 Hertz, which mirrors the conditions under which electrical equipment operates during normal circumstances. The primary goal of this test is to assess the insulation integrity of various electrical components by subjecting them to voltages higher than their rated levels. This helps identify any weaknesses in the insulation that could lead to failure during actual operation.

The power frequency spark test machine is designed to produce high-voltage outcomes that mimic potential fault conditions. By doing this in a controlled environment, engineers can determine how various materials and devices will respond to potential electrical stresses, thereby enhancing safety protocols.

Components and Functionality

A typical power frequency spark test machine consists of several components including a high-voltage transformer, a control panel, and a testing chamber. The high-voltage transformer steps up the input voltage to the necessary levels (often in the range of tens of kilovolts). The control panel allows operators to set and monitor voltage levels, duration of the test, and safety features.

During testing, the device to be evaluated is placed in the testing chamber. The machine then applies a specified voltage while monitoring for any electrical discharges or breakdowns in the insulation. The occurrence of a spark or arc indicates insulation failure, while the absence of any such discharges suggests that the equipment can withstand the applied stress.

power frequency spark test machine

Applications of Power Frequency Spark Test Machines

Power frequency spark test machines find extensive usage across various industries. They are particularly significant in the manufacturing of electrical equipment, where ensuring the reliability and safety of products like capacitors, cables, and circuit breakers is paramount. These tests are crucial before the deployment of such equipment in power distribution networks, as they help prevent potential failures that could lead to catastrophic outages or safety hazards.

Moreover, utility companies utilize these machines during routine maintenance checks to assess the condition of existing infrastructure. By regularly testing transformers, switches, and other electrical components, utilities can proactively address issues before they escalate into significant problems, thus ensuring continuous, reliable service for consumers.

Importance of Safety and Standards

The use of power frequency spark test machines is governed by stringent safety standards and regulations. It is essential that operators are trained and familiar with both the operation of the machine and the associated safety protocols. High-voltage testing presents inherent hazards, and the equipment must be used in designated testing environments to mitigate risks.

Moreover, adherence to standardized testing procedures ensures the integrity of results. Testing standards, typically outlined by organizations such as IEEE (Institute of Electrical and Electronics Engineers) and IEC (International Electrotechnical Commission), guide the testing processes. These standards help maintain a universal quality level across industries and ensure that all testing results are comparable.

Conclusion

Power frequency spark test machines are vital tools in the maintenance and quality assurance of electrical equipment. By simulating high-voltage conditions, they enable engineers to evaluate insulation properties and ensure system reliability. As reliance on electricity continues to grow, the importance of such testing methods will only increase. Professionals in the field must remain informed about the latest advancements in testing technology and adhere to best practices to promote safety and efficiency in electrical engineering.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy