power frequency spark test machine suppliers

Power Frequency Spark Test Machine Suppliers Ensuring Electrical Safety and Reliability

In the realm of electrical testing, the power frequency spark test plays a crucial role in ensuring the safety and reliability of electrical insulation systems. This test assesses the dielectric strength of insulating materials under high voltage conditions, simulating real-world operating environments. As industries increasingly prioritize safety and compliance with international standards, the demand for reliable power frequency spark test machines has surged, leading to the emergence of numerous suppliers in the market.

Power frequency spark test machines are designed to apply a specified voltage to an insulation specimen until breakdown occurs. This process helps to identify weaknesses and potential failures in electrical systems, making it an essential part of quality assurance in manufacturing processes. Suppliers of these specialized machines offer a range of products, from portable units for field testing to sophisticated, computer-controlled systems for laboratory environments.

When selecting a power frequency spark test machine supplier, several key factors should be considered

1. Product Quality and Standards The machines must adhere to recognized standards such as IEC, IEEE, and ASTM. Trusted suppliers often provide equipment that has been rigorously tested and certified, ensuring compliance with safety regulations.

power frequency spark test machine suppliers

2. Customization Options Different applications may require specific testing parameters. Leading suppliers often offer customizable solutions to meet unique testing needs, allowing companies to select voltage levels, test durations, and additional features tailored to their requirements.

3. Technical Support and Training Suppliers should offer comprehensive customer support, including installation, maintenance, and user training. Knowledgeable technicians can assist operators in understanding the nuances of the equipment, ensuring accurate results and prolonged machine life.

4. Reputation and Experience Suppliers with a long-standing reputation in the industry are typically more reliable. Established companies often have the experience to provide guidance on best practices and emerging trends in testing methodologies.

5. Cost-Effectiveness While initial investment is important, consider the long-term value of the equipment, including its durability, maintenance costs, and accuracy. Comparing different suppliers can help identify options that offer the best balance of cost and performance.

In conclusion, the selection of a power frequency spark test machine supplier is a critical decision that can significantly impact electrical safety and operational efficiency. By emphasizing product quality, customization, support, reputation, and cost, organizations can ensure they choose a supplier that meets their unique testing needs and upholds the highest safety standards. Ultimately, investing in reliable testing equipment safeguards both personnel and valuable assets, fostering a culture of safety and compliance in electrical engineering.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

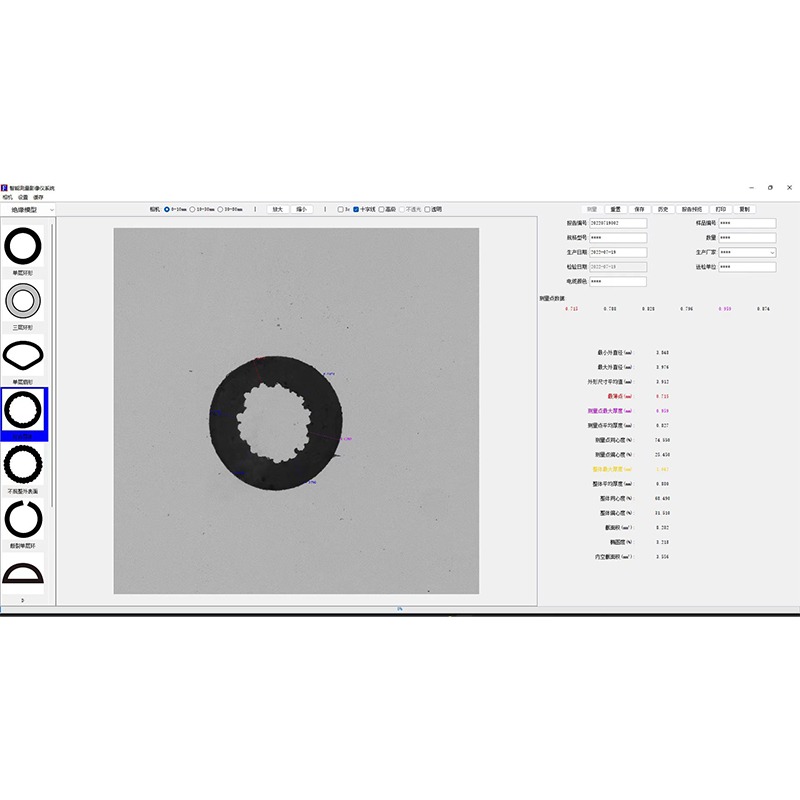

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy