Profile Projector - Precision Measurement Tools for Professional Use

Understanding the Profile Projector A Comprehensive Guide

The profile projector, also known as an optical comparator, plays a quintessential role in the realm of precision measurement and quality control in various engineering fields. This sophisticated optical instrument serves to project a magnified image of a workpiece silhouette onto a glass screen, allowing engineers and technicians to inspect and measure the contours and geometrical features with outstanding accuracy.

At the heart of the profile projector's functionality is its use of high-intensity light sources, often LED, which illuminate the object from below. The light casts the part's profile onto the projection surface, typically a transparent screen marked with measuring grids. This illuminated projection takes advantage of the principles of optics to provide an overview of the object's dimensions and shapes, which can then be analyzed for conformity with design specifications.

One of the key features of the profile projector is its ability to highlight minute details that may not be easily visible to the naked eye. By enlarging images, users can detect imperfections, such as burrs, scratches, or dimensional variances, ultimately ensuring that the components meet quality standards. Engaging with a profile projector allows for the inspection of complex geometries, from intricate machined parts to delicate molded components, making it a versatile tool across different industries, including automotive, aerospace, medical device manufacturing, and more.

profile projector

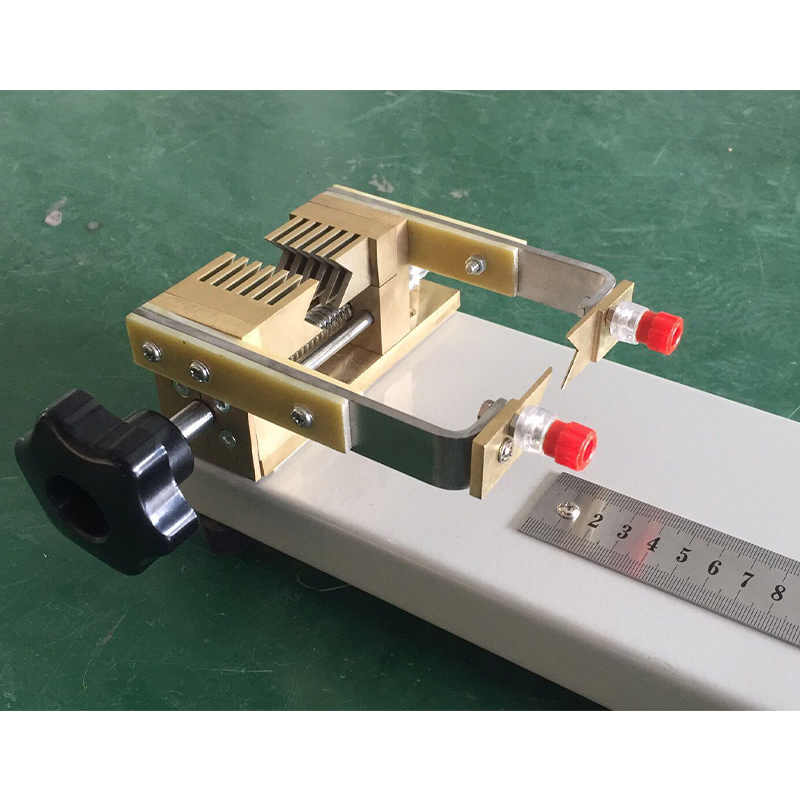

When performing measurements, operators typically employ various attachments, such as measuring reticles or overlays that can be superimposed onto the projected image. This feature allows for precise angular measurements, radius checks, and even identification of geometric tolerances per industry standards. The integration of digital measuring systems and software further elevates the capabilities of modern profile projectors, incorporating features like data logging, automated measurements, and computer-aided design (CAD) compatibility.

Using a profile projector is not only about precision; it also enhances productivity. By reducing the time spent on manual measurements and inspections, manufacturers can achieve operational efficiency. The ease of use associated with these machines allows operators to focus on critical assessments rather than becoming mired in complex measurement processes.

Moreover, the benefits of employing profile projectors extend to the documentation and traceability of measurements. In industries governed by strict regulatory standards, such as aerospace or pharmaceuticals, maintaining accurate records of inspections is vital. Many profile projectors can output measurement results to computers for archiving, which facilitates audits and supports quality assurance practices.

In conclusion, the profile projector is an essential tool for engineers and quality control professionals, providing a perfect balance of precision, efficiency, and reliability. As industries continue to evolve and demand higher standards, the role of the profile projector will remain integral, ensuring that components meet necessary specifications and, ultimately, enhancing the safety and performance of the end products. Whether for routine inspections or intricate measurements, the profile projector remains a cornerstone of modern manufacturing and engineering practices.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy