profile projectors exporter

The Role of Profile Projectors in Modern Manufacturing

In today's fast-paced manufacturing industry, precision is not just desirable; it is essential. In this quest for accuracy, profile projectors have emerged as invaluable tools for engineers and manufacturers alike. These instruments, which project a magnified silhouette of a manufactured part onto a screen, facilitate meticulous measurements and inspections. Not only do they enhance quality control processes, but they also ensure that components fit seamlessly in their intended applications. As a result, the export of profile projectors has seen a significant rise, reflecting their growing importance in various sectors, including aerospace, automotive, and electronics.

What is a Profile Projector?

Profile projectors, also known as optical comparators, are sophisticated measuring tools that provide a two-dimensional representation of an object. By utilizing a powerful light source to project the image of the profile onto a glass screen, operators can compare the actual dimensions of a part to its intended specifications. This comparison is essential for identifying defects in geometry, dimensions, and overall design, thereby preventing costly mistakes downstream in the manufacturing process.

Applications in Different Industries

1. Aerospace Industry The aerospace sector is perhaps one of the most demanding fields regarding precision. Profile projectors are widely used for measuring intricate parts used in aircraft and spacecraft. Components must meet stringent standards for safety and functionality, making the role of profile projectors critical for manufacturers.

2. Automotive Manufacturing The automotive industry relies on profile projectors to ensure that parts such as gears, brackets, and shafts meet tight tolerance specifications. The ability to effectively gauge surface imperfections and make necessary adjustments before parts enter assembly lines directly impacts the overall performance and reliability of vehicles.

3. Electronics and Telecommunications In the electronics sector, profile projectors aid manufacturers in producing circuit boards and other complex components with exacting standards. The ability to quickly and accurately measure tiny dimensions is crucial for the functionality of electronic devices.

profile projectors exporter

The Export Market for Profile Projectors

As global manufacturing continues to expand, so does the demand for profile projectors. Countries with advanced manufacturing infrastructures, such as Germany, Japan, and the United States, are not the only players in this space. Nations across Asia and Europe are increasingly investing in quality assurance tools, including profile projectors. As a result, the export of profile projectors has become an increasingly lucrative market.

Manufacturers that specialize in these tools are exploring new markets, establishing partnerships, and catering their offerings to meet the unique demands of various regions. For instance, the growing manufacturing base in Southeast Asia presents both challenges and opportunities. Companies that can provide efficient, reliable, and competitively priced profile projectors are likely to succeed in this dynamic environment.

Innovation and Technology

The landscape of profile projectors is continuously evolving. Recent advancements in technology have led to the development of digital profile projectors that combine traditional projection methods with modern digital imaging. These devices can store measurements, create reports, and even integrate with other measurement systems for enhanced accuracy and efficiency. The shift towards automation and digital solutions is opening new avenues for the export of profile projectors, appealing to a tech-savvy workforce that requires efficient and precise tools.

Conclusion

Profile projectors are an integral component of modern manufacturing, ensuring that the parts produced meet the highest standards of quality and precision. As industries seek to improve their manufacturing processes, the demand for these tools will likely continue to grow. This trend presents a robust opportunity for exporters of profile projectors, who can meet the needs of a rapidly evolving market. By investing in innovation and adapting to technological advancements, manufacturers can not only seize potential growth but also contribute to the overall advancement of quality assurance practices in various industrial sectors. The future looks bright for profile projectors in the global marketplace.

-

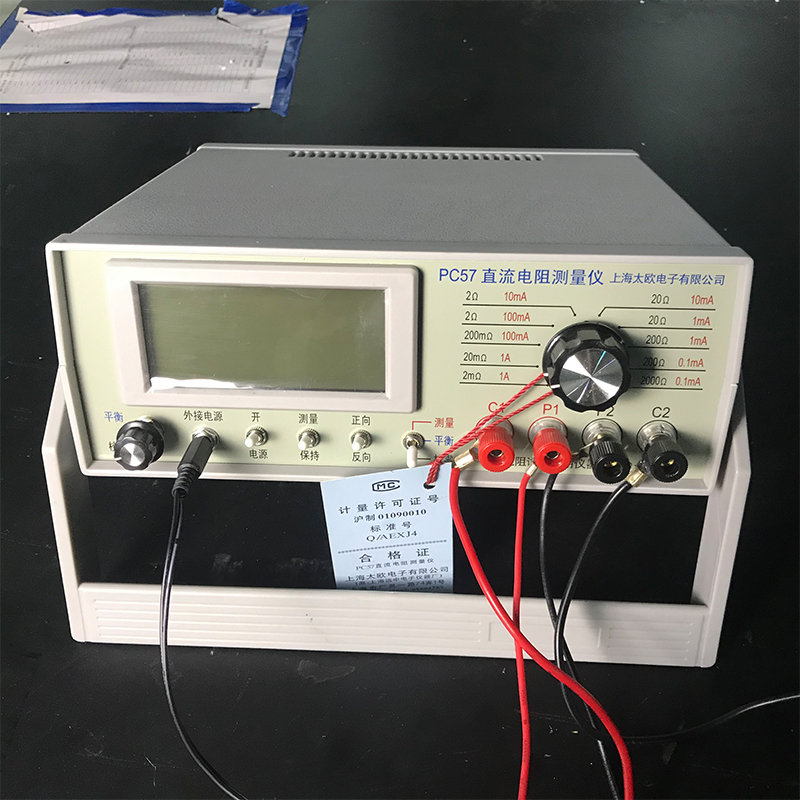

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy