Profile Projectors Manufacturing and Quality Control Solutions for Precision Measurement

Profile Projectors An Essential Tool in Modern Manufacturing

In the fast-evolving landscape of modern manufacturing, precision and accuracy have become critical factors that determine a company's success. Among the various tools available to manufacturers, profile projectors stand out for their ability to deliver both detailed measurement and inspection capabilities. This article explores the significance of profile projectors, their working principles, and their applications in a factory setting.

Profile projectors, also known as optical comparators, are sophisticated measuring instruments designed to project the silhouette of an object onto a screen. This projection allows engineers and quality control specialists to evaluate the dimensions and geometries of parts with unparalleled accuracy. In a factory environment where tolerances can be as tight as a few microns, the utility of profile projectors becomes invaluable.

Profile Projectors An Essential Tool in Modern Manufacturing

One of the standout features of profile projectors is their ease of use. Unlike complex CNC machines or laser measurement systems, profile projectors require minimal training to operate effectively. This accessibility allows manufacturers to integrate them into their quality control processes without extensive delays. Furthermore, their compact design makes them suitable for various production environments, from small workshops to large assembly lines.

profile projectors factory

Applications of profile projectors extend far beyond merely measuring dimensions. They are instrumental in industry sectors such as aerospace, automotive, and medical device manufacturing, where precision is paramount. Engineers utilize profile projectors to verify the accuracy of intricate parts, ensuring they meet stringent industry standards. In addition, they assist in reverse engineering processes by allowing engineers to analyze existing components and recreate accurate CAD models.

In a factory setting, regular calibration of profile projectors is crucial to maintaining their accuracy and reliability. Many manufacturers schedule routine maintenance checks and calibration to ensure that measurements remain within acceptable tolerances. This emphasis on precision can significantly reduce waste and rework, thereby improving overall productivity.

Moreover, the advancement of technology has led to the emergence of digital profile projectors. These modern versions incorporate electronic measurement capabilities, enabling automated data recording and analysis. Digital interfaces enhance user experience while providing instant feedback and storing measurement data for future reference.

In conclusion, profile projectors play a vital role in modern manufacturing by providing essential measurement and inspection capabilities. Their simplicity, versatility, and precision make them an invaluable tool for quality control in a variety of industries. As manufacturers continue to strive for higher efficiency and accuracy, the importance of profile projectors is likely to grow, cementing their position as a cornerstone of effective manufacturing practices. For companies looking to enhance their quality assurance processes and stay competitive in the market, investing in a profile projector is a step in the right direction.

-

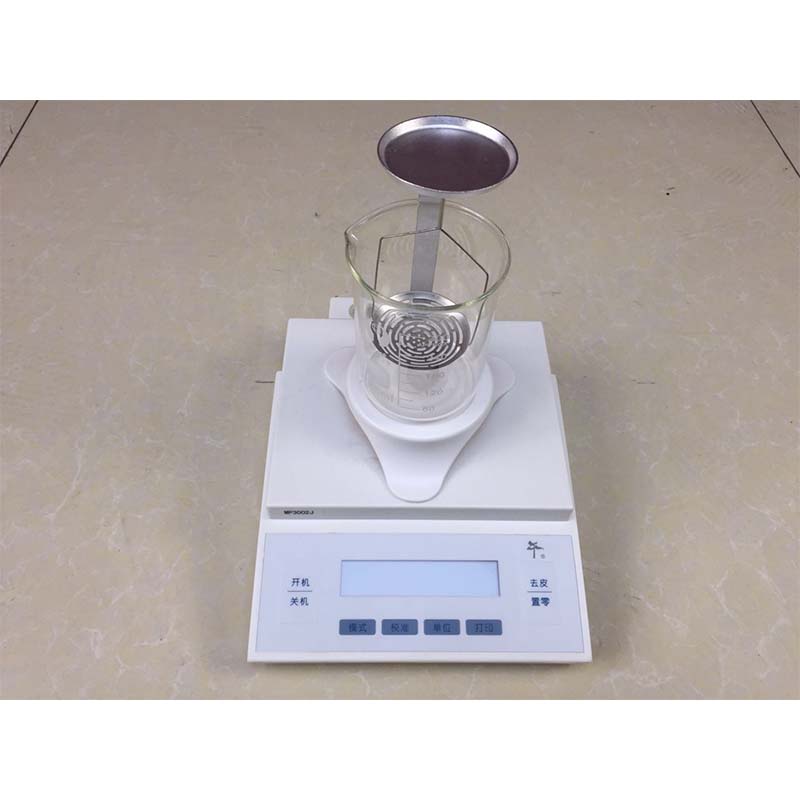

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy