Factories Specializing in Projector Measuring Machine Production and Development

The Advancements in Projector Measuring Machine Factories

In recent years, the demand for precision measurement tools has surged, driven by advancements in manufacturing processes, quality control needs, and technological innovations. Among these tools, projector measuring machines (PMMs) have emerged as indispensable instruments in factories. These machines are known for their ability to accurately measure the dimensions and geometry of various components, especially in industries such as automotive, aerospace, and electronics. Let’s delve into the operations of PMM factories and their significance in modern manufacturing.

Understanding Projector Measuring Machines

Projector measuring machines utilize a combination of optics and coordination systems to measure the physical dimensions of parts. The principle is straightforward an image of the component is projected onto a screen, and operators can then use calibrated measuring tools to determine dimensions and tolerances. PMMs can deliver extremely precise measurements, often within micrometers, which is crucial for industries where precision is a key criterion for success.

The Manufacturing Process

The production of projector measuring machines is a complex process that involves multiple stages

. Factories engaged in their manufacture typically start with the selection of high-quality materials. Components such as the projection lens, mirrors, and electronic systems must meet stringent quality standards to ensure the final product performs reliably.After materials are sourced, the manufacturing stage involves several sub-processes, including machining, assembly, and calibration. Advanced CNC machines are often used to create the intricate parts of the PMMs, ensuring that each component is manufactured to exact specifications. Following this, skilled technicians assemble these parts, taking care to align optical components accurately.

One critical aspect of PMM factories is calibration. Each machine must be meticulously calibrated to account for minute discrepancies that could affect measurement accuracy. This step typically involves the use of standard reference objects, ensuring that the machinery delivers precise results.

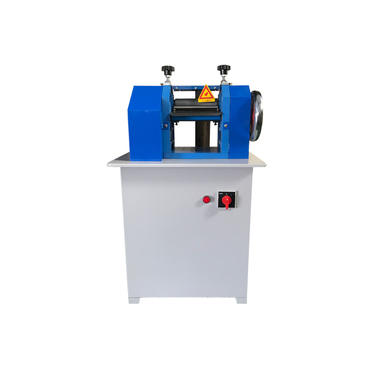

projector measuring machine factories

Technological Innovations

The PMM industry has seen various technological innovations that enhance the capabilities of measurement machines. For instance, the integration of digital technology has revolutionized how measurements are taken and recorded. Digital displays and software now allow users to analyze data in real time, significantly increasing efficiency and reducing the potential for human error.

Additionally, the advent of automated systems in PMM factories has streamlined production processes. Automation helps in achieving consistent quality, faster production rates, and reduced labor costs. Factories can now implement robots for assembly tasks, handling materials, and even in the calibration process, leading to increased overall productivity.

The Importance of Quality Control

Quality control is a crucial component of the operations in PMM factories. With industries striving for higher standards, the role of projector measuring machines has become even more pivotal. By ensuring that every part meets the specified tolerances, PMMs help manufacturers avoid costly errors and maintain product integrity.

Furthermore, the presence of rigorous quality control measures plays a vital role in achieving customer satisfaction. As industries become increasingly competitive, customers expect impeccable quality. PMM factories not only assist in maintaining standards but also contribute to the overall enhancement of manufacturing practices.

Conclusion

Projector measuring machine factories are leading the charge in the pursuit of precision and quality in manufacturing. The intricate processes involved in the production of PMMs, coupled with cutting-edge technologies and rigorous quality controls, underscore the importance of these machines in the modern industrial landscape. As technology continues to advance, we can expect further innovations in PMMs, solidifying their role as essential tools in various industries. In an era where quality is paramount, the factories that produce these machines are crucial allies for manufacturers aiming for excellence.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy