purchasing tensile tester companies

Purchasing Tensile Testers Key Considerations and Leading Companies in the Market

In the realm of material testing, tensile testers play a crucial role in evaluating the mechanical properties of materials. These devices are essential for industries ranging from construction to manufacturing, as they provide vital data on how materials behave under tension. When considering the purchase of a tensile tester, it is important to understand the various types available, the factors influencing your choice, and the leading companies in the market.

Understanding Tensile Testers

A tensile tester, also known as a tensile testing machine or universal testing machine, is designed to measure the tensile strength, elongation, and other mechanical properties of materials when subjected to a controlled tension force. The results obtained are critical for quality control, product development, and compliance with industry standards.

There are several types of tensile testers, including manual, semi-automatic, and fully automatic models. Manual testers are often used for simple applications and might require some manual intervention during testing. Semi-automatic and fully automatic testers are suited for more complex materials and higher throughput, allowing for automated data collection and analysis.

Key Considerations for Purchasing a Tensile Tester

When considering the purchase of a tensile tester, several factors should be taken into account

1. Specifications and Capabilities Evaluate the range of testing capabilities. This includes maximum load capacity, elongation measurement, and the types of materials the tester can handle (such as metals, plastics, composites, etc.). Ensure the machine meets the requirements for the specific materials you will be testing.

2. Standards Compliance Look for testers that comply with international standards such as ASTM, ISO, or EN standards. Compliance ensures that the testing methods and results will be recognized and accepted in different industries.

3. Ease of Use The user interface and software compatibility should be user-friendly, allowing for easy operation and data analysis. Consider whether the system includes features such as automatic calibration and real-time data display.

4. Support and Service Reliable customer service and technical support are crucial. Check if the company offers training, maintenance services, and readily available spare parts.

purchasing tensile tester companies

5. Budget Determine your budget, keeping in mind that a higher initial investment can result in better features and reliability. Also, consider the long-term costs, including potential repair and maintenance expenses.

Leading Companies in the Tensile Tester Market

Several reputable companies specialize in manufacturing tensile testers, each offering unique features and advantages. Here are some of the leading companies in the industry

1. Instron With over 70 years of experience, Instron is a prominent player in the materials testing industry. They offer a wide range of tensile testing machines, including models equipped with advanced software for comprehensive analysis.

2. MTS Systems Corporation MTS specializes in both testing and simulation solutions. Their tensile testers are known for their precision and reliability, often used in aerospace, automotive, and structural applications.

3. Tinius Olsen Established in 1880, Tinius Olsen is a well-known manufacturer of material testing equipment. Their testers are designed for versatility and ease of use, making them suitable for a variety of industries.

4. Shimadzu Corporation Based in Japan, Shimadzu is recognized globally for its high-quality testing equipment. They provide specialized tensile testers that cater to different materials and testing standards.

5. ZwickRoell A prominent European provider, ZwickRoell focuses on testing technology and offers solutions that include tensile testers with innovative features for accurate and efficient testing.

Conclusion

Purchasing a tensile tester is a significant investment for any organization involved in material testing. By understanding the types of testers available, evaluating your specific needs, and considering leading manufacturers in the market, you can make an informed decision that will support your testing requirements for years to come. Whether for quality control, product development, or research purposes, the right tensile tester can provide the critical data needed to ensure material integrity and performance.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

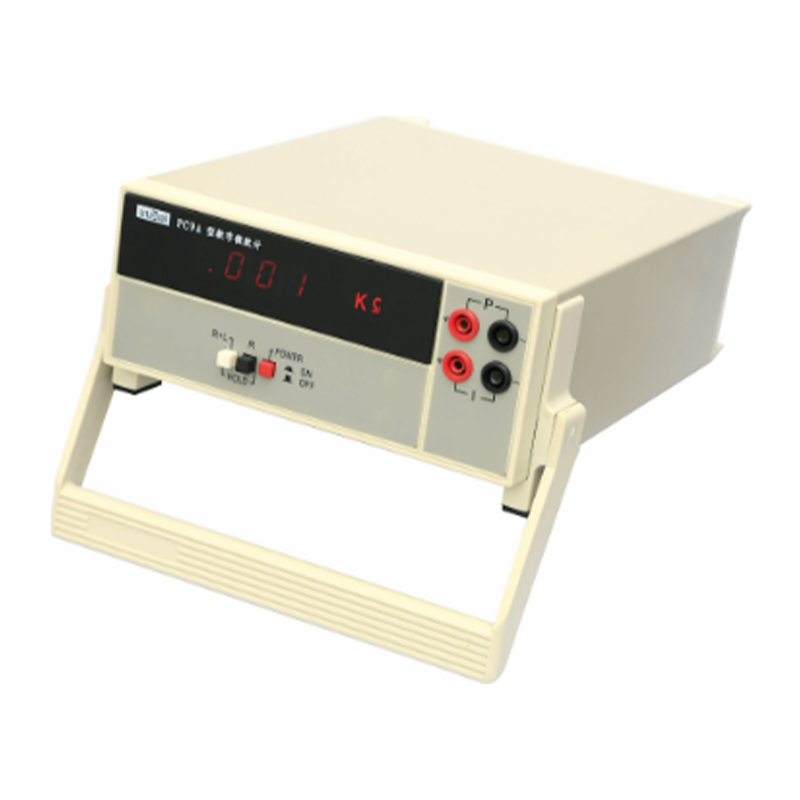

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy