Choosing the Right Tensile Tester for Your Manufacturing Needs and Quality Control

Exploring Purchasing Options for Tensile Tester Factories

When it comes to quality assurance in manufacturing, tensile testing is an essential process. This method evaluates the strength and durability of materials, ensuring that products meet necessary standards before they reach consumers. For businesses seeking to enhance their production quality, sourcing a reliable tensile tester factory is paramount.

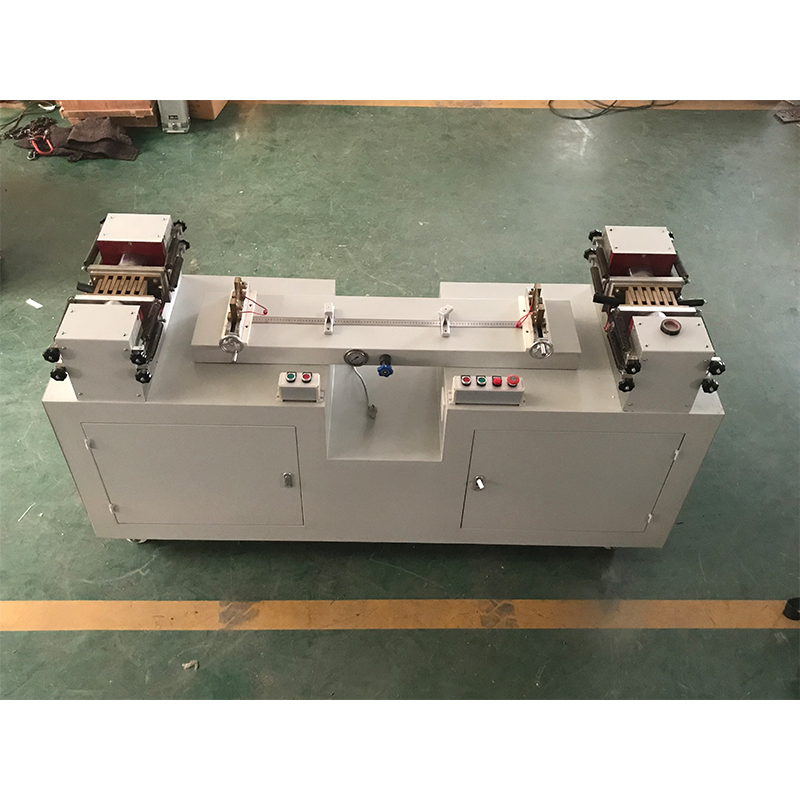

Tensile test machines are used to determine how materials will react under tension. Factors such as tensile strength, yield strength, elongation, and reduction of area are measured, providing vital information for product development and quality control. As industries continually evolve, the demand for precise and efficient testing equipment has surged. Consequently, firms now find themselves exploring various purchasing options for tensile testers.

When considering a tensile tester factory, it is crucial to evaluate several key factors. First, the factory's reputation and experience in the industry can significantly influence the quality of the equipment. Established manufacturers are more likely to provide reliable, accurately calibrated machines and valuable insights about operation and maintenance. Researching customer reviews and industry ratings can give potential buyers a clearer picture of a factory's reliability.

Another important consideration is the range of products offered by the factory. A good tensile tester factory should provide a variety of testing machines that cater to different material types and testing standards. From universal tensile testing machines to specialized setups for polymers or metals, having options allows businesses to select the most appropriate equipment for their testing needs.

purchasing tensile tester factory

Moreover, technological advancements play a significant role in today's testing solutions. Factories that invest in state-of-the-art technology and innovation offer equipment with enhanced features such as computerized data analysis, easy-to-use interfaces, and improved accuracy. These advancements not only streamline the testing process but also contribute to more comprehensive data collection, allowing for better material evaluation.

Additionally, customer support and training offered by the factory are vital components to consider. A manufacturer that provides in-depth training on the usage of their machines, along with ongoing technical support, ensures that businesses can effectively utilize their products and maintain operational efficiency.

Lastly, budget considerations cannot be overlooked. While it's essential to invest in quality equipment, prospective buyers should balance their needs with financial constraints. Comparing prices and features across different factories can help businesses find cost-effective solutions that do not compromise on quality.

In conclusion, purchasing from a tensile tester factory requires careful consideration of reputation, product range, technology, support, and budget. By thoroughly evaluating these factors, businesses can invest in tensile testing equipment that enhances their production quality and meets industry standards.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy