purchasing tensile tester manufacturer

Purchasing a Tensile Tester A Guide to Choosing the Right Manufacturer

When it comes to quality control and materials testing, a tensile tester is an essential piece of equipment for businesses in various industries, including plastics, metals, textiles, and composites. These machines measure the tensile strength, elongation, and other properties of materials to ensure they meet industry standards. As such, purchasing a tensile tester is a significant investment that requires careful consideration, particularly in selecting a reliable manufacturer.

Understanding the Importance of a Quality Manufacturer

The performance and accuracy of a tensile tester heavily depend on the quality of its construction and the technology employed by the manufacturer. A reputable manufacturer will offer machines that adhere to international testing standards, ensuring that the results obtained are reliable and comparable. When selecting a manufacturer, it’s crucial to research their history and reputation in the industry. Look for companies with a strong track record of producing durable and precise testing equipment.

Key Factors to Consider

1. Technical Specifications Different applications require different testing capabilities. Consider what maximum load and elongation requirements your tests will demand. Make sure the manufacturer provides a range of models that suit your specific needs, including features such as digital displays, automatic data logging, and user-friendly interfaces.

purchasing tensile tester manufacturer

2. Customization Options Depending on your sector, you may need a tensile tester that is customized to accommodate specific materials or testing conditions. A good manufacturer should offer flexible solutions and be willing to work with you to modify their products to fit your needs.

3. Calibration and Compliance Verify that the manufacturer provides calibration services and that their equipment meets ISO or ASTM standards. Regular calibration is crucial for maintaining accuracy in material testing, and having a manufacturer that offers these services can save you time and resources in the long run.

4. Customer Support and Warranty Choose a manufacturer known for excellent customer service. Make sure they offer comprehensive support, including installation guidance, training for your staff, and ongoing maintenance. A solid warranty is indicative of the manufacturer’s confidence in their products and offers peace of mind for your investment.

5. Reviews and Testimonials Reading reviews and testimonials from other customers can provide insights into the performance and reliability of a manufacturer’s products. Look for feedback on product quality, customer service, and overall satisfaction.

Conclusion

Purchasing a tensile tester is a critical decision that impacts the quality of your materials and products. By selecting the right manufacturer, you can ensure that you receive a machine that meets your testing needs and stands up to the rigors of daily use. Take the time to evaluate different manufacturers based on their reputation, technical offerings, and customer service to make an informed choice. Investing in a quality tensile tester will ultimately enhance your testing capabilities and contribute to the reliability of your products in the marketplace.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

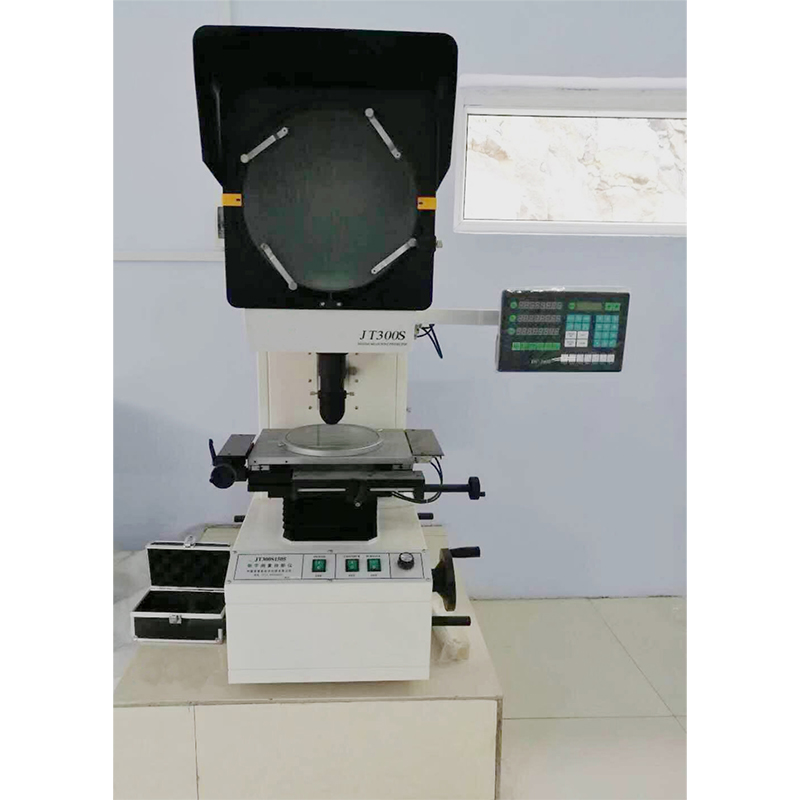

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy