purchasing tensile tester manufacturer

Purchasing a Tensile Tester What to Consider and Key Manufacturers

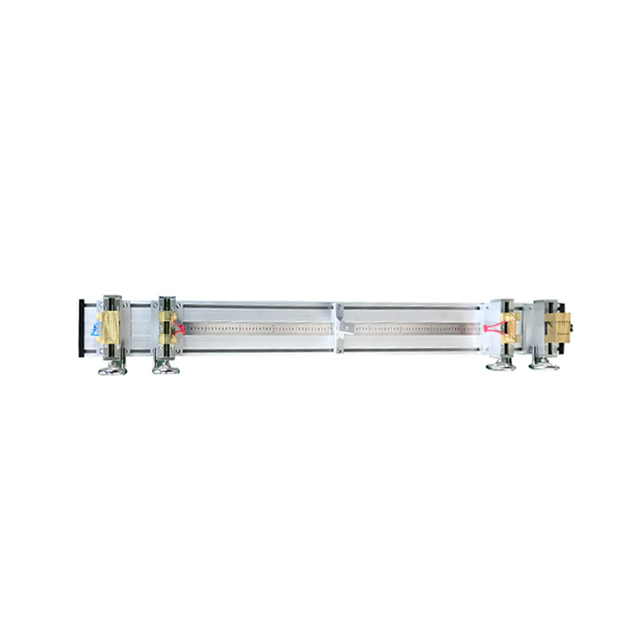

When it comes to evaluating material properties, a tensile tester is an essential piece of equipment for various industries, including manufacturing, construction, and research laboratories. It measures the strength and ductility of materials by applying a uniaxial force until failure occurs. Given its importance, purchasing a tensile tester requires careful consideration of several factors, including the type of testing needed, budget constraints, and the manufacturer reputation.

Understanding Your Testing Needs

Before embarking on the purchasing journey, it's crucial to identify the specific requirements of your operations. Different materials (metals, plastics, textiles, etc.) may require different testing standards and configurations. Additionally, consider the maximum load capacity you'll need and whether you'll require accessories for specific tests, such as grips, extensometers, or environmental chambers.

The type of tests you intend to perform also influences your choice. Do you need to conduct standard tensile tests, or are specialty tests required? It’s beneficial to compile a list of mandatory specifications and features to narrow down your options effectively.

Budget Considerations

Tensile testers come in a range of prices, from budget models suitable for basic testing to high-end systems designed for advanced research applications. It’s advisable to establish a budget early in the process, considering both the initial purchase price and potential ongoing costs related to maintenance, calibration, and additional accessories. Sometimes, spending a little more initially will save costs down the line by ensuring accurate results and minimizing the need for replacements.

Key Manufacturers to Consider

purchasing tensile tester manufacturer

There are several reputable manufacturers in the market known for producing high-quality tensile testers

. Here are a few notable options1. Instron A leader in materials testing, Instron offers a wide range of tensile testers suited for different materials and applications. Their systems are known for their high precision and advanced software capabilities, making it easier to analyze test results.

2. MTS Systems Corporation MTS provides solutions that cater to both static and dynamic testing needs. Their tensile testers are designed for flexibility, allowing users to perform various types of mechanical tests on a single platform.

3. ZwickRoell Known for innovative designs, ZwickRoell’s testers are ideal for a wide variety of materials. They offer user-friendly interfaces and robust software for data management, making it suitable for both novice and experienced operators.

4. Tinius Olsen This manufacturer has a long history in materials testing. Their tensile testers come with different configurations to meet specific testing requirements, and their customer support is noteworthy.

5. Shimadzu Another strong contender, Shimadzu offers versatile testing systems recognized for their durability and reliability. Their tensile testers are equipped with advanced features that facilitate comprehensive analysis.

Conclusion

When purchasing a tensile tester, understanding your specific testing needs is paramount. Take into account the budget, the types of materials being tested, and the required specifications. Exploring various manufacturers is essential to ensure you choose a product that meets your requirements while providing reliable performance. By making informed decisions, you can enhance the quality control processes in your operations, ensuring that your materials meet industry standards and customer expectations.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy