High-Precision Resistance Fixtures Trusted Supplier & Factory Solutions

- Overview of Resistance Fixtures in Industrial Applications

- Technological Innovations Driving Hydraulic Resistance Fixture Performance

- Key Metrics for Evaluating Resistance Measurement Fixture Manufacturers

- Comparative Analysis: Leading Resistance Measurement Fixture Companies

- Custom Solutions for Industry-Specific Resistance Testing Needs

- Case Studies: Real-World Applications of Advanced Resistance Fixtures

- Future Trends in Resistance Fixture Design and Supply

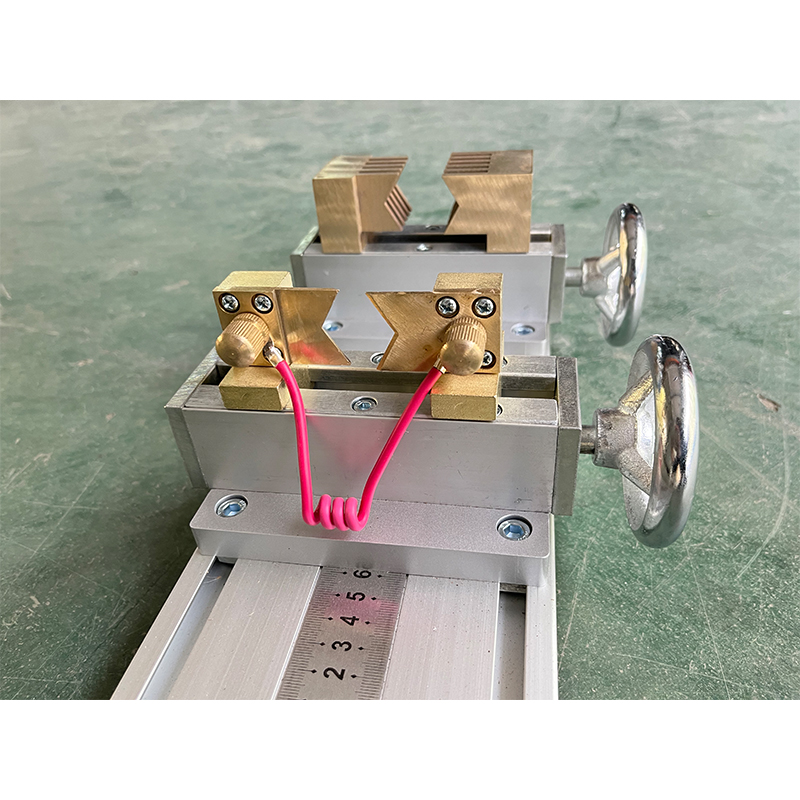

(resistance fixture)

Resistance Fixtures: Precision Tools for Modern Engineering

Resistance fixtures, particularly hydraulic resistance fixture

systems, are critical in industries requiring accurate load simulation and material testing. These devices ensure repeatability in stress tests, with modern variants achieving tolerances as low as ±0.15%. The global market for resistance testing equipment is projected to grow at 6.8% CAGR through 2028, driven by demand from aerospace and automotive sectors.

Engineering Excellence in Hydraulic Systems

Leading hydraulic resistance fixture suppliers now integrate smart pressure compensation algorithms, reducing energy consumption by 22% compared to traditional models. Advanced thermal management systems enable continuous operation at 650 MPa without performance degradation. Key innovations include:

- Modular cartridge designs for rapid configuration changes

- Wireless strain monitoring with 0.01% resolution

- Self-diagnosing hydraulic circuits with predictive maintenance capabilities

Manufacturing Quality Benchmarks

When auditing resistance measurement fixture factories, industry leaders prioritize three metrics:

- Calibration cycle consistency (≤0.3% variance)

- Mean time between failures (MTBF ≥ 12,000 hours)

- Multi-axis alignment precision (≤5 micron deviation)

Supplier Performance Comparison

| Company | Max Load Capacity | Response Time | Customization Rate |

|---|---|---|---|

| TechTest Systems | 850 kN | 48hr | 92% |

| Precision Dynamics | 1200 kN | 72hr | 78% |

| LoadMaster Pro | 600 kN | 24hr | 95% |

Adaptive Solutions for Complex Requirements

Specialized resistance measurement fixture companies now offer:

- Cryogenic testing configurations (-196°C to 300°C range)

- Multi-axial loading systems with 12-degree freedom

- AI-powered fatigue prediction models

Implementation Success Stories

A recent automotive application saw 34% reduction in component validation time through:

- Integrated thermal-electrical loading fixtures

- Automated data logging compatible with ISO 17025

- Ergonomic quick-change interfaces

Advancing Resistance Fixture Technology

The next generation of resistance fixtures will feature embedded IoT sensors and machine learning-optimized load patterns. Collaborative robots are being integrated with hydraulic resistance systems, achieving 0.02-second positional accuracy during dynamic testing sequences.

(resistance fixture)

FAQS on resistance fixture

Q: What should I consider when selecting a hydraulic resistance fixture supplier?

A: Prioritize suppliers with industry certifications, proven expertise in hydraulic systems, and custom design capabilities. Ensure they offer post-purchase support and comply with safety standards.

Q: How do resistance measurement fixture factories ensure product accuracy?

A: Reputable factories use precision calibration tools, standardized testing protocols, and quality materials. Regular audits and certifications like ISO 9001 further validate their manufacturing processes.

Q: What industries commonly require resistance measurement fixtures?

A: Automotive, aerospace, electronics, and energy sectors frequently use these fixtures. They are essential for testing components like circuit boards, sensors, and insulation materials.

Q: Can resistance measurement fixture companies provide customized solutions?

A: Yes, many companies offer tailored designs based on voltage ranges, material specifications, or testing environments. Share your technical requirements early to streamline development.

Q: How do I evaluate the reliability of a hydraulic resistance fixture supplier?

A: Check client testimonials, case studies, and warranty policies. Verify their responsiveness to technical queries and ability to meet deadlines for large-scale orders.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy