Understanding Resistance Percentage in Testing Fixtures for Improved Performance

Understanding Resistance Fixtures Importance and Applications

In the world of electrical engineering and testing, resistance fixtures play a critical role in ensuring accurate measurements and validations of electrical components. These specialized tools are designed to create specific resistance levels, allowing engineers and technicians to assess the performance of various devices under test conditions. As electronic devices become increasingly integral to our daily lives, understanding the significance of resistance fixtures is more relevant than ever.

What is a Resistance Fixture?

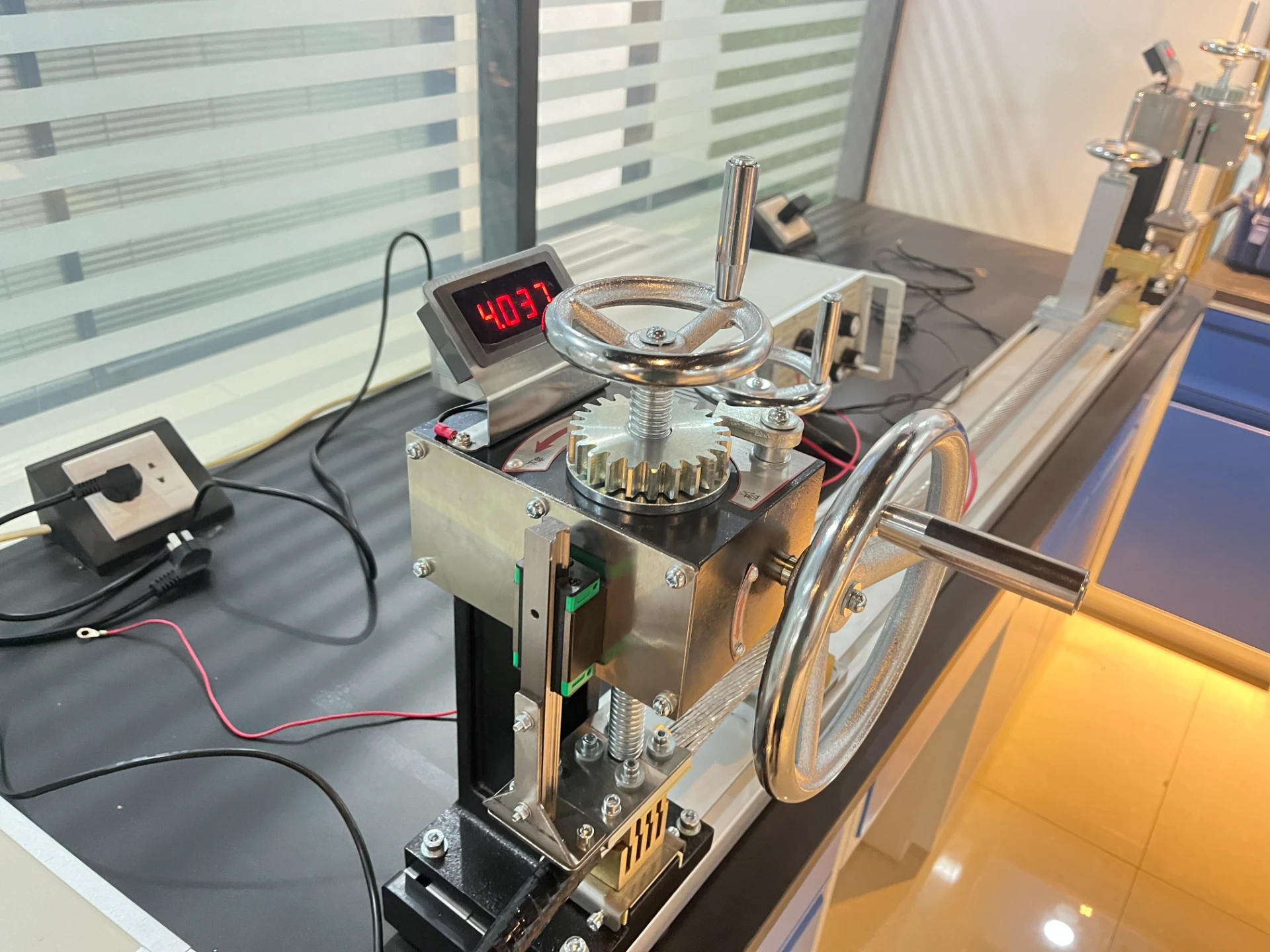

A resistance fixture is a device used to establish a reproducible resistance value within a test setup. It typically consists of resistive elements, connectors, and sometimes integrated circuits designed to test the performance of electrical devices, such as circuit boards, sensors, and other electronic components. The primary purpose of these fixtures is to provide a stable and known resistance that can be connected to a device under test (DUT), enabling accurate measurements of current, voltage, and power.

The construction of resistance fixtures can vary significantly depending on the application. Some fixtures use standard fixed resistors, while others are adjustable, allowing for a range of resistive values. More advanced models may incorporate digital interfaces for automated testing and data collection, making them essential in both laboratory settings and production environments.

Importance of Resistance Fixtures

1. Accuracy in Testing One of the pivotal functions of resistance fixtures is to ensure accurate testing of components. By providing a precise resistance value, these fixtures help eliminate variables that might affect test outcomes. This reliability is crucial in quality control processes, where even minor deviations can impact overall product performance.

2. Standardization Resistance fixtures help standardize testing procedures. When all components are tested using the same resistance values and conditions, the results are more comparable. This standardization is vital in industries where compliance with regulatory standards is mandatory, ensuring that products meet safety and performance benchmarks.

resistance fixture

3. Enhanced Efficiency Using resistance fixtures can significantly streamline the testing process. By reducing the time spent on calibrating equipment and adjusting resistance values, engineers can focus on analyzing results and improving designs. This efficiency gains importance in high-volume production environments, where time is often equated with cost.

4. Versatility Resistance fixtures can be designed for various applications, making them versatile tools in testing. From simple resistive loads for basic components to complex configurations for integrated circuits, these fixtures cater to a wide range of electrical and electronic testing requirements.

5. Troubleshooting and Development In the design and development phase of electronic products, resistance fixtures are invaluable. They allow engineers to simulate different operating conditions, helping to identify potential issues before the product goes to market. Whether assessing how a device handles various loads or determining failure points, these fixtures provide critical insights.

Applications of Resistance Fixtures

Resistance fixtures find applications across various sectors, including

- Consumer Electronics Testing the performance of smartphones, televisions, and other gadgets. - Automotive Ensuring the reliability of electronic components in vehicles, such as sensors and control units. - Aerospace Validating components used in flight systems, where accuracy and reliability are paramount. - Telecommunications Assessing the performance of circuit boards and antenna systems used in communication devices.

Conclusion

In conclusion, resistance fixtures are fundamental to contemporary electronic testing and validation processes. Their role in ensuring accuracy, efficiency, and standardization cannot be understated. As technology continues to advance, the relevance and sophistication of these fixtures will undoubtedly evolve, paving the way for more innovative solutions in the testing landscape. For engineers and technicians, mastering the use of resistance fixtures is essential for producing reliable, high-quality electronic devices that meet consumer demands and industry standards.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy