Resistance Measurement Clamp Manufacturers and Their Innovations in Testing Solutions

The Importance of Resistance Measurement A Deep Dive into Clamp Factories

In the ever-evolving landscape of electrical engineering, measuring resistance accurately is crucial for ensuring the optimal performance and safety of electrical systems. Among the various methods of resistance measurement, clamp meters have emerged as an indispensable tool for professionals in the field. This article delves into the significance of resistance measurement, focusing specifically on clamp factories that play a pivotal role in producing these essential instruments.

Understanding Resistance Measurement

Resistance measurement is a fundamental aspect of electrical engineering, as it helps in assessing the integrity of electrical circuits. Resistance, defined as the opposition to the flow of electric current, can affect the efficiency and safety of electrical devices. High resistance may lead to poor performance, while low resistance could result in overheating and potential hazards. Therefore, accurate resistance measurements are critical in maintaining the reliability and safety of electrical systems.

The Role of Clamp Meters

Clamp meters are specialized devices designed to measure the current flowing through a conductor without the need for direct contact. They work on the principle of magnetic induction, allowing users to clamp the device around a wire and obtain a reading. Some advanced clamp meters also offer resistance measurement capabilities, which adds to their versatility. By providing quick and accurate resistance readings, these tools are essential for electricians, technicians, and engineers.

The Importance of Clamp Factories

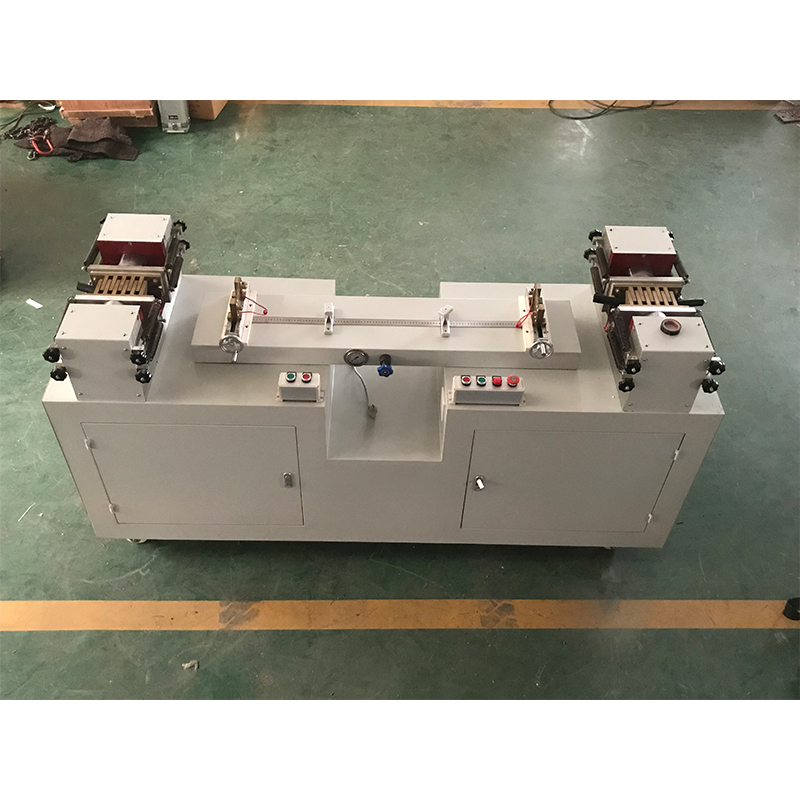

resistance measurement clamp factories

Clamp factories are at the forefront of producing high-quality clamp meters that meet the diverse needs of the electrical industry. These factories are equipped with advanced technology and skilled labor to ensure that the products are reliable and efficient. To maintain competitiveness and meet market demands, clamp factories must adhere to strict quality control standards throughout the manufacturing process.

1. Quality Assurance The significance of quality assurance in clamp factories cannot be overstated. Each clamp meter undergoes rigorous testing to ensure it meets industry standards. This includes calibration tests for accuracy, durability assessments, and safety checks to prevent malfunctions that could pose risks to users.

2. Innovation in Design As technology advances, so too does the need for innovative designs in clamp meters. Manufacturers are increasingly incorporating smart technology, such as Bluetooth connectivity and data logging features, which enhance the usability and functionality of clamp meters. This innovation not only improves user experience but also expands the applications of these devices across various sectors.

3. Customization Options Different industries have unique requirements, and clamp factories recognize this need for customization. By offering tailor-made solutions, they can cater to the specific needs of clients, whether it be for industrial applications, HVAC systems, or electrical service providers.

4. Sustainability Practices Increasing environmental awareness has led clamp factories to adopt sustainable manufacturing practices. This includes the use of eco-friendly materials, waste reduction techniques, and energy-efficient production processes. By prioritizing sustainability, these factories are not only benefiting the environment but also enhancing their brand reputation among conscious consumers.

Conclusion

Resistance measurement through clamp meters is more than just a technical necessity; it is a critical factor for ensuring electrical systems function safely and efficiently. The role of clamp factories in producing reliable and innovative measuring instruments cannot be overlooked. By focusing on quality, innovation, customization, and sustainability, these factories are shaping the future of electrical measurement technology. As we continue to rely on electricity in our daily lives, the importance of accurate resistance measurement and high-quality clamp meters remains paramount, safeguarding both our devices and our well-being.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy