Innovative Solutions for Precision Resistance Measurement Equipment and Technology

The Importance of Resistance Measurement Machines in Industrial Applications

In today’s rapidly evolving technological landscape, the accuracy and reliability of electronic components are critical for ensuring the performance and longevity of devices. One of the key parameters that engineers need to measure in electronic components is resistance. Resistance measurement machines play a crucial role in this process, ensuring that manufacturers can deliver high-quality products that meet strict industry standards.

What is Resistance Measurement?

Resistance measurement refers to the process of quantitatively assessing the electrical resistance of a material or component. This measurement is essential in a variety of applications, including the production of resistors, capacitors, and other electronic components. The resistance of a material affects how it behaves in a circuit, influencing everything from energy loss to the thermal stability of the component.

Resistance measurement machines have become indispensable tools in modern manufacturing and testing environments. These machines facilitate the assessment of resistance with high precision, allowing manufacturers to ensure that their components operate as intended.

Types of Resistance Measurement Machines

There are several types of resistance measurement machines available in the market, each designed to cater to specific requirements

1. Digital Multimeters (DMMs) These versatile instruments are commonly used in laboratories and workshops for various electrical measurements, including resistance. They offer high accuracy and can measure a wide range of resistance values.

2. Micro-ohmmeters These machines are specialized for measuring very low resistances, which is particularly important for applications in power systems and for testing connections in circuitry.

3. Bridge Instruments Resistance bridge devices are often utilized in laboratories for high-precision resistance measurements. These instruments are particularly essential for calibrating other measurement devices.

4. Automated Test Equipment (ATE) In mass production environments, ATE systems are used to perform resistance measurements automatically. They enhance efficiency, reduce human error, and aid in quality assurance processes.

resistance measurement machine company

The Role of Resistance Measurement in Quality Control

Quality control is an imperative aspect of manufacturing. Resistance measurement machines are integral to the quality assurance processes that ensure components meet specified criteria. For instance, in the automotive and aerospace industries, resistive components must adhere to stringent tolerance levels to ensure safety and performance.

Manufacturers utilize resistance measurement machines during various stages of production, from raw material assessment to final component testing. By implementing these measurements, they can identify defects early in the production process, which significantly reduces the risk of failures in the final product.

Advancements in Resistance Measurement Technology

The field of resistance measurement has seen significant advancements in recent years, driven largely by technological innovations. Some of the noteworthy developments include

- Enhanced Accuracy Modern resistance measurement machines utilize advanced algorithms and components that offer higher levels of accuracy than traditional devices, enabling more reliable measurements.

- Data Connectivity Many contemporary resistance measurement machines are equipped with data logging and connectivity features, allowing users to collect, analyze, and share measurement data seamlessly. This is particularly useful for remote monitoring and for integrating with larger quality control systems.

- User-Friendly Interfaces With advancements in software design, many resistance measurement machines now offer intuitive interfaces that simplify the measurement process, reducing the need for extensive training for operators.

Conclusion

Resistance measurement machines are essential tools in the quality control process within various industries, ranging from electronics to automotive and aerospace. As technology continues to evolve, these machines are becoming more accurate, efficient, and user-friendly. For companies invested in producing high-quality electronic components, implementing reliable resistance measurement processes is not just beneficial; it is essential for maintaining competitiveness in today’s fast-paced manufacturing environment. Ultimately, ensuring the integrity of resistance measurements leads to better products and increased customer satisfaction in an increasingly demanding market.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

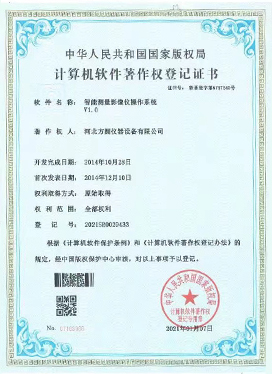

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy