resistance test

Understanding Resistance Testing Ensuring System Reliability and Performance

In today's technology-driven world, the reliability of systems and components is paramount. One essential aspect of ensuring that reliability is through rigorous testing methods, among which resistance testing plays a crucial role. This testing process evaluates the electrical resistance of various components and systems, helping to identify issues that could lead to failures or inefficiencies.

Resistance testing involves measuring the opposition to the flow of electric current in a given component, typically expressed in ohms (Ω). The basic principle behind this type of testing is Ohm's Law, which states that the resistance (R) is equal to the voltage (V) divided by the current (I). By applying this principle, technicians can assess whether a component is functioning within its specified resistance range. This information is vital for ensuring optimal performance and longevity of electrical and electronic systems.

One common application of resistance testing is in the assessment of insulation in electrical equipment. Insulation resistance testing can help in detecting degradation due to environmental factors, mechanical wear, or thermal stress. For example, in motors, transformers, and generators, the insulation can break down over time, leading to short circuits and, ultimately, failure. By performing regular resistance tests, maintenance professionals can identify potential failures before they escalate, allowing for timely repair or replacement and reducing downtime.

Additionally, resistance testing is crucial in the manufacturing process of electronic components. Manufacturers conduct these tests on circuit boards, connectors, and other items to ensure they meet quality standards before they leave the production line. By verifying that components possess the correct resistance values, manufacturers can avoid costly recalls or warranty issues later on. This quality control step not only enhances customer satisfaction but also protects the company’s reputation and financial investment.

resistance test

Resistance testing is not limited to industrial applications; it also plays a significant role in residential settings. Homeowners often use simple resistance testing tools to check the integrity of electrical systems and appliances. For example, testing the resistance of power cords and outlets can help identify frayed wires or poor connections, preventing electrical hazards such as fires or shocks. Such proactive measures contribute significantly to home safety and energy efficiency.

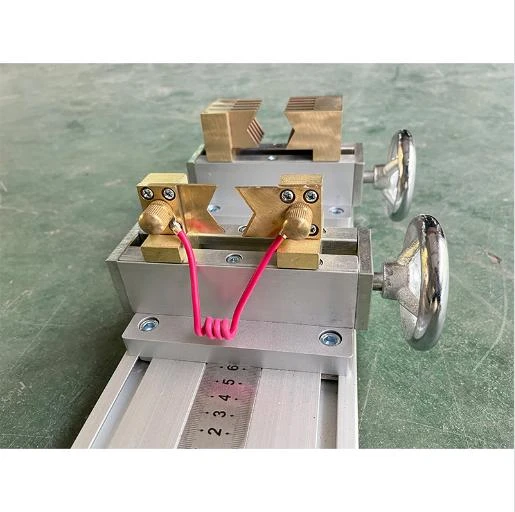

Moreover, advancements in technology have led to the development of sophisticated resistance testing equipment that provides more accurate and comprehensive results. Digital multimeters, insulation resistance testers, and low-resistance ohmmeters are examples of tools that professionals use to conduct these tests. These devices often come equipped with features such as data logging, wireless capability, and easy-to-read displays, allowing for better analysis and record-keeping.

The importance of resistance testing extends beyond safety and quality assurance; it also has significant implications for energy efficiency. By identifying components that exhibit high resistance, technicians can pinpoint areas where energy is being wasted and take corrective actions. This can involve replacing outdated equipment, improving connections, or even redesigning systems to minimize resistance. Ultimately, enhancing energy efficiency not only reduces operational costs but also contributes to environmental sustainability by lowering energy consumption.

In conclusion, resistance testing is an essential practice that plays a critical role in various industries and applications. Whether in manufacturing, maintenance, or residential settings, understanding and conducting resistance tests can prevent failures, enhance safety, and ensure the reliability of systems. As technology continues to evolve, the methods and tools for conducting resistance tests will likely become even more advanced, further emphasizing the importance of this fundamental testing technique in our increasingly electrified world.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy