resistance tester factories

The Significance of Resistance Tester Factories in Modern Industry

In today’s rapidly evolving technological landscape, the demand for precise and reliable testing equipment has never been greater. Among these instruments, resistance testers play a crucial role in various sectors, including electrical, automotive, and manufacturing industries. This article delves into the significance of resistance tester factories and how they contribute to innovation and quality assurance.

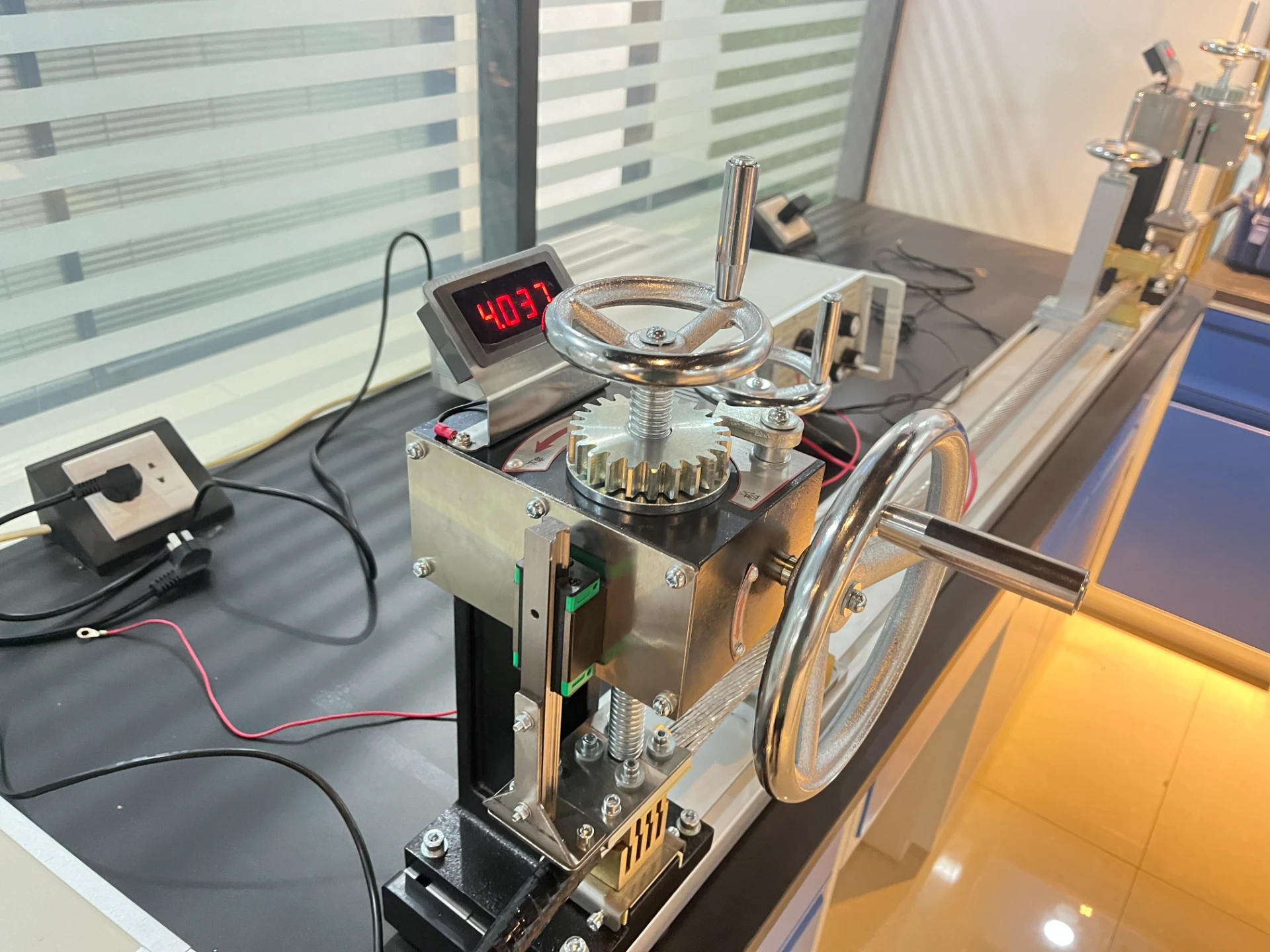

Resistance testers, or ohmmeters, are used to measure electrical resistance in circuits and components. Accurate measurements are essential for ensuring the safety and efficiency of electrical systems. Consequently, resistance tester factories are pivotal in producing high-quality devices that meet industry standards. These factories employ advanced manufacturing techniques and stringent quality control processes to develop testers that can withstand rigorous testing environments and deliver reliable results.

One of the primary advantages of specialized resistance tester factories is their ability to innovate. The field of electrical engineering is constantly evolving, with new materials and technologies emerging regularly. Factories dedicated to resistance testers invest in research and development to keep pace with these changes. This commitment to innovation leads to the creation of more sophisticated and user-friendly testing devices. For instance, modern resistance testers often feature digital displays, automated functions, and connectivity options that allow for data logging and remote monitoring, greatly enhancing their usability.

resistance tester factories

Moreover, resistance tester factories contribute to standardization across the industry. As manufacturers of testing equipment, they adhere to international standards set by organizations such as the International Electrotechnical Commission (IEC) and the Institute of Electrical and Electronics Engineers (IEEE). By ensuring that their products meet these rigorous standards, resistance tester factories not only comply with legal requirements but also optimize performance and reliability. Standardization fosters trust among users and promotes greater consistency in testing results, which is vital for maintaining safety in electrical applications.

Furthermore, the globalization of manufacturing has led to an increase in the competition among resistance tester factories. This competition drives quality improvements and cost reductions, ultimately benefiting end-users. Factories that can deliver superior products at competitive prices often gain a larger market share. As a result, they are motivated to refine their manufacturing processes, enhance their supply chains, and adopt sustainable practices that minimize their environmental impact. By prioritizing sustainability, these factories also cater to the growing demand for eco-friendly products, aligning with global efforts to address climate change.

The importance of resistance tester factories extends beyond thermal measurements; they also contribute significantly to workforce development. As these factories require skilled technicians and engineers, they often establish training programs that equip individuals with the necessary skills to operate advanced testing equipment. This not only enhances the workforce's capabilities but also promotes technological literacy and innovation within communities.

In conclusion, resistance tester factories play a vital role in modern industry by providing essential testing equipment that ensures the safety and efficacy of electrical systems. Their commitment to innovation, adherence to industry standards, and focus on sustainability underscore their significance in a rapidly changing technological landscape. As the demand for reliable testing instruments continues to rise, these factories will remain at the forefront of ensuring quality and performance, shaping the future of various industries worldwide.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy