resistance tester factory

Understanding the Resistance Tester The Backbone of Quality Assurance

In the world of electronics and electrical engineering, the importance of reliable testing and measurement cannot be overstated. From ensuring the safety of devices to enhancing performance and longevity, thorough testing processes are essential. One of the pivotal tools in any engineer’s arsenal is the resistance tester, which plays a crucial role in evaluating the electrical resistance of materials and components. This article explores the functionality, manufacturing, and importance of resistance testers within the context of a resistance tester factory.

What Is a Resistance Tester?

A resistance tester, often referred to as an ohmmeter, is a device used to measure the resistance of various materials, typically ranging from ohms to megohms. These testers are essential in identifying faults, ensuring proper electrical connections, and determining the integrity of devices in various applications including automotive, telecommunications, and consumer electronics.

The Manufacturing Process

The production of resistance testers within a factory setting involves multiple stages, ensuring that the final product adheres to strict quality standards. The typical manufacturing process can be broken down into several key phases

1. Design and Prototyping The initial phase of resistance tester production begins with the design of the device. Engineers use computer-aided design (CAD) software to create prototypes, focusing on accuracy, user interface, and the incorporation of technology such as digital displays and Bluetooth connectivity for modern applications.

2. Component Sourcing Once the design is approved, the next step is sourcing high-quality components, such as resistors, capacitors, and microcontrollers. This is crucial, as the accuracy and durability of the tester greatly depend on the quality of these parts.

3. Assembly The assembly of the resistance testers typically involves both manual labor and automated machinery. Skilled technicians and robots work together to ensure each part is accurately placed and soldered, minimizing the risk of human error.

4. Quality Control After assembly, each unit undergoes rigorous testing to ensure it meets predetermined specifications. Quality control teams assess accuracy across various resistance levels, durability through stress tests, and functionality in real-world conditions.

resistance tester factory

The Importance of Resistance Testers in Various Industries

Resistance testers are integral in many industries, owing to their ability to provide critical insights into the functionality and safety of electronic components. Here are a few applications

- Electrical Safety Testing In the electrical industry, resistance testers are pivotal in ensuring that electrical systems adhere to safety standards. They help detect insulation failures, confirming that electrical devices are safe for usage. - Manufacturing Quality Assurance In manufacturing, resistance testers ensure that components function effectively before and after assembly, reducing the risk of failures that could lead to product recalls.

- Automotive Industry Within the automotive sector, diagnosing electrical issues in vehicles can often require precise resistance measurements. Engineers utilize resistance testers to troubleshoot car electronics, including battery conditions and ignition systems.

- Telecommunications In telecommunications, maintaining the integrity of connections is essential. Resistance testers ensure that connections between various components do not compromise the quality of signals transmitted.

Future Trends in Resistance Testing

As technology evolves, resistance testers are becoming increasingly sophisticated. Modern testers integrate advanced features such as data logging, wireless connectivity, and mobile application compatibility, offering users greater convenience and functionality. Furthermore, the rise of automation and IoT (Internet of Things) technologies is driving the development of smart resistance testers, capable of performing remote diagnostics and facilitating predictive maintenance.

Conclusion

In summary, resistance testers are invaluable tools that significantly influence the reliability and safety of electronic and electrical devices. The rigorous manufacturing processes observed in resistance tester factories ensure that only the highest quality products reach the market. As advancements in technology continue to reshape the landscape of electrical testing, resistance testers will undoubtedly remain at the forefront, innovating alongside the industries they support. Investing in quality resistance testers is, therefore, a step towards ensuring operational excellence and safety in the increasingly complex world of electronics.

-

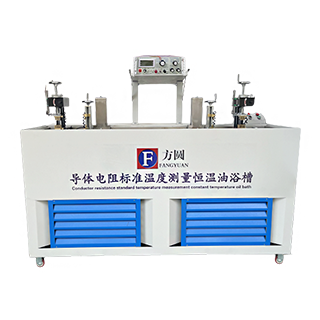

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy