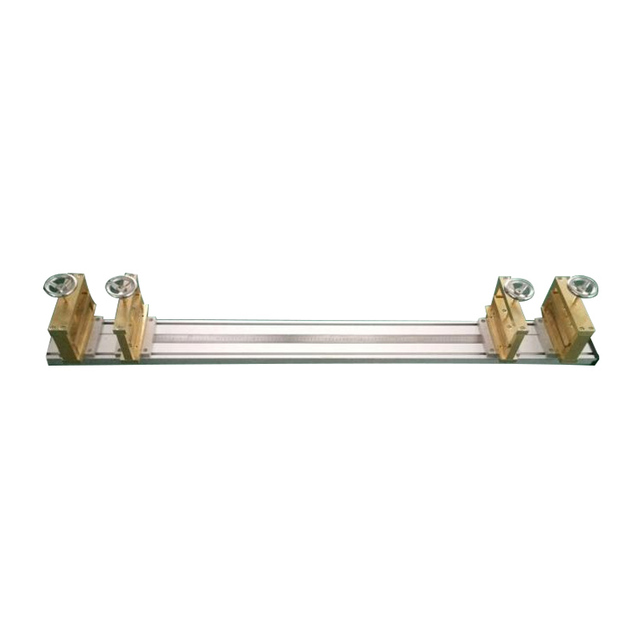

resistance test machine

Understanding Resistance Test Machines A Key Tool in Material Testing

In the field of material science and engineering, the integrity and reliability of materials are paramount. Engineers and manufacturers rely heavily on resistance test machines to evaluate the performance and durability of various materials under different conditions. These machines play a crucial role in industries ranging from construction to electronics, ensuring that products meet safety and quality standards.

What is a Resistance Test Machine?

A resistance test machine is designed to assess the electrical resistance of materials, especially those that are expected to conduct electricity. These machines apply an electrical current to the material and measure its resistance, which is essential for determining the material's suitability for specific applications. The resistance of a material can be influenced by several factors, including temperature, material composition, and physical characteristics.

Importance of Resistance Testing

The importance of resistance testing cannot be overstated. In electrical and electronic applications, materials with low resistance are often preferred to ensure efficient current flow. Conversely, materials with high resistance are critical for insulation purposes, preventing unwanted current leakage. By using resistance test machines, engineers can ensure that materials meet the required specifications for their intended use, thus enhancing product safety and effectiveness.

Common Applications

Resistance test machines are used in a variety of applications across multiple industries. In the electrical industry, they help assess the quality of conductors and insulating materials. For instance, in power cables, testing the insulation resistance is essential to ensure that the cable can operate safely under high voltages without failing.

In the automotive industry, resistance testing is crucial for components like battery connectors and motor windings, where ensuring low resistive losses is vital for efficiency and performance. Furthermore, in the telecommunications sector, these machines are indispensable in assessing the quality of cables used in data transmission, where high-quality signals depend on low resistance pathways.

Types of Resistance Test Machines

resistance test machine

Resistance test machines come in various forms, each tailored to specific testing needs. Some common types include

1. Digital Multimeters These handheld devices are widely used for basic resistance measurements in both laboratory and field settings. They provide quick readings and are essential tools for technicians.

2. Micro-ohm Meters Specifically designed for measuring low resistances, micro-ohm meters are used in applications where precision is critical, such as in testing the resistance of connectors and busbars in electrical installations.

3. Insulation Resistance Testers Often referred to as megohm meters, these testers apply a high voltage to gauge the resistance of insulating materials. They are crucial in ensuring the safety and functionality of electrical installations.

Advancements in Resistance Testing Technology

With technological advancements, resistance test machines have become more sophisticated. Many modern machines are equipped with digital interfaces and software that allow for data logging, remote monitoring, and automated testing protocols. This not only enhances accuracy but also increases efficiency in testing operations.

Moreover, the integration of artificial intelligence (AI) and machine learning is beginning to transform how resistance testing is conducted. Predictive analytics can help manufacturers anticipate failures based on resistance data trends, enabling proactive maintenance and reducing downtime.

Conclusion

Resistance test machines are vital tools in ensuring material quality and performance across various industries. Their ability to measure and analyze resistance allows engineers to select appropriate materials and design reliable products. As technology continues to evolve, these machines will become even more integral to material testing, paving the way for innovations in safety and efficiency. By investing in robust resistance testing procedures, companies can enhance product quality, ensure safety, and maintain a competitive edge in their respective markets.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy