semi-conductive shielding resistance test

Semiconductive Shielding Resistance Test Ensuring Reliable Electrical Performance

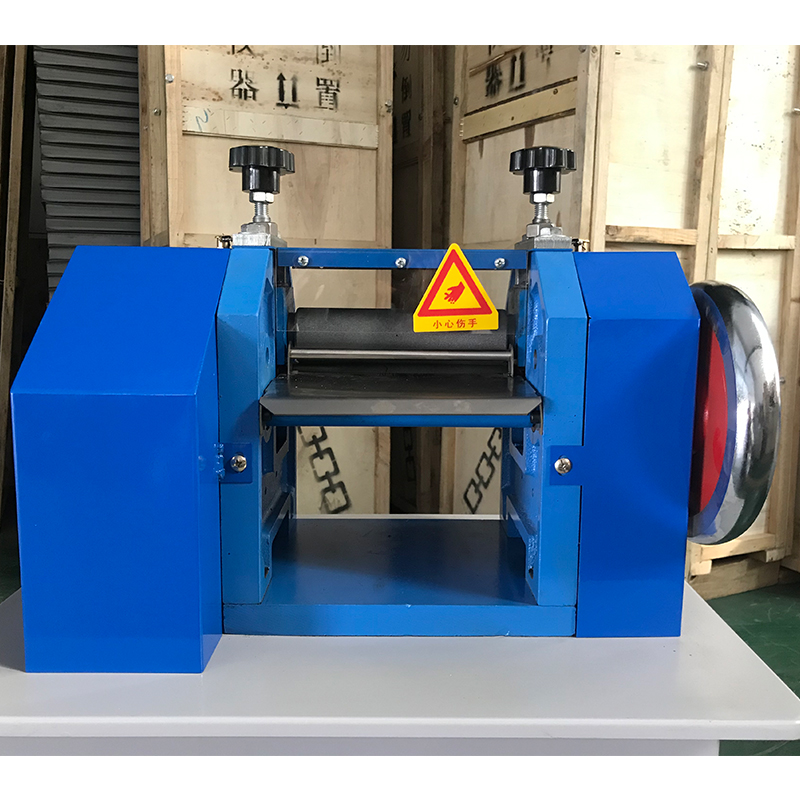

In today's technologically advanced world, the significance of effective electrical shielding cannot be overstated. Among various methodologies to measure and ensure the quality of shielding materials, the semi-conductive shielding resistance test plays a crucial role. This test is critical for verifying the electrical performance of cables, especially in environments with high electromagnetic interference (EMI).

Semiconductive shielding is commonly used in cables to provide a conductive path to ground, thereby protecting sensitive electronic equipment from electromagnetic radiation. Properly designed and installed shielding materials must exhibit specific resistance characteristics to effectively dissipate electrical noise. The semi-conductive shielding resistance test measures the resistivity of the semi-conductive layer, ensuring that it meets industry standards.

The test involves applying a known voltage to the shielding material while measuring the current that flows through it. Using Ohm's law, the resistance can be calculated. An optimal resistance value is essential; too high a resistance can lead to inadequate shielding, while too low a resistance may cause excessive current flow, potentially damaging the cable.

semi-conductive shielding resistance test

To conduct this test accurately, it is essential to prepare the sample correctly. The cable should be stripped back at both ends to expose the semi-conductive layer, ensuring a reliable contact point for the probes. It’s also important to maintain a controlled environment during testing, as temperature and humidity can influence resistance readings.

After preparing the sample, the testing apparatus should be calibrated to ensure precision. The results are compared against defined standards set forth by organizations such as the International Electrotechnical Commission (IEC). If the resistance falls within acceptable limits, the shielding is deemed effective; if not, it indicates a potential failure in the shielding layer that may need corrective action.

The importance of this test extends beyond mere compliance with regulations. In many applications, particularly in the aerospace, telecommunications, and healthcare sectors, superior shielding can mean the difference between operational reliability and catastrophic failure. Consequently, regular testing of components not only facilitates quality assurance but also enhances safety.

In conclusion, the semi-conductive shielding resistance test serves as a vital measure of electrical integrity in shielding materials. By ensuring that cables meet established resistance standards, manufacturers and engineers can provide assurances against EMI, thereby promoting the reliability and longevity of electrical systems. As technology continues to evolve, the importance of effective shielding and rigorous testing will only increase, underscoring the need for ongoing research and development in this field.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy