Testing the Shielding Resistance of Semi-Conductive Materials in Manufacturing Processes

Understanding Semi-Conductive Shielding Resistance Testing in Manufacturing

In the world of electrical engineering, the importance of various testing methods cannot be overstated. One such critical test is the semi-conductive shielding resistance test, particularly significant in the manufacturing of cables and connectors that require effective electromagnetic interference (EMI) shielding. This article delves into the concept of semi-conductive shielding, the need for resistance testing, and the methodologies used in factories to ensure optimal performance.

What is Semi-Conductive Shielding?

Semi-conductive shielding refers to a layer of material applied to electrical cables, typically made from a compound that exhibits both conductive and insulating properties. This semi-conductive layer helps in controlling the electromagnetic fields surrounding the cable, thereby reducing EMI. These shielding materials are crucial in various applications, especially in industries such as telecommunications, aerospace, automotive, and any sector where signal degradation could lead to potential failures or safety concerns.

The semi-conductive layer functions by providing a path for the electrical charges that may accumulate in the insulation, thus safely dissipating them and minimizing the chances of electrical stress on the cable insulator. It is essential, therefore, that the effectiveness of this shielding is routinely tested during the manufacturing process.

The Importance of Resistance Testing

Resistance testing of semi-conductive shields is vital for several reasons. First, it ensures that the shielding is working efficiently, providing adequate protection against EMI. If the resistance is too high, it can lead to shielding failure and potential signal interference. Conversely, if the resistance is too low, it may indicate a risk of electrical shorts or unsafe conditions.

Moreover, regulatory standards often require resistance testing to ensure compliance with industry specifications. Non-compliance not only compromises performance but can also lead to legal ramifications and damage to corporate reputation. Therefore, implementing rigorous testing measures during production is not just a best practice but a necessary protocol.

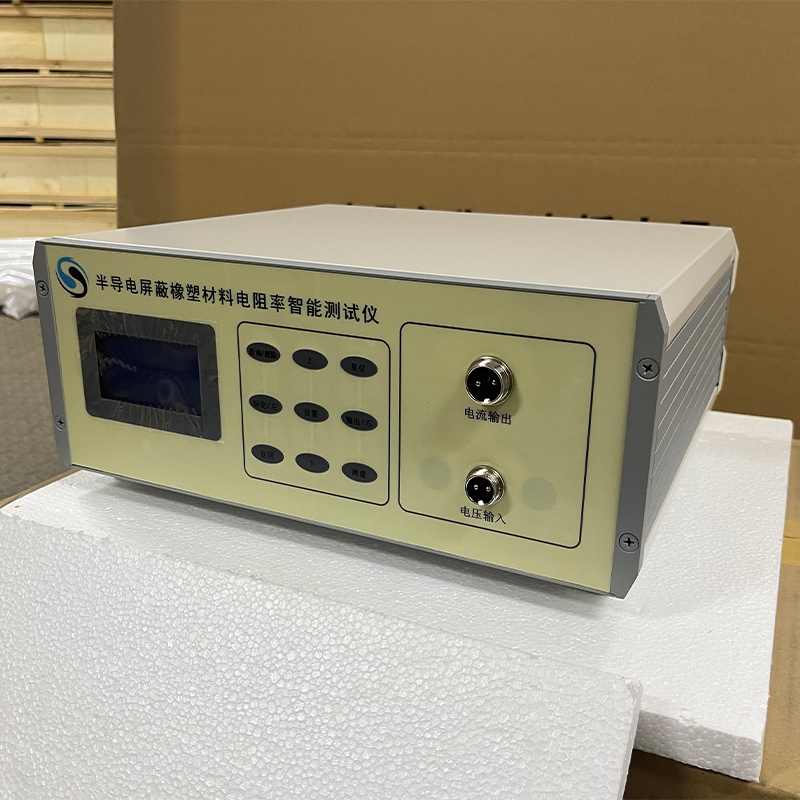

semi-conductive shielding resistance test factory

Testing Methodologies

In factories, various methodologies are utilized to conduct semi-conductive shielding resistance tests. The most common methods include

1. Direct Resistance Measurement This method involves using a multimeter to measure the resistance of the semi-conductive material directly. Technicians will typically apply a specific voltage and measure the current to determine resistance according to Ohm's Law (R = V/I).

2. Insulation Resistance Test This involves applying a high voltage to the insulation of the cable and measuring the leakage current. This data helps to assess the effectiveness of the semi-conductive shielding in maintaining its insulating properties.

3. Shielding Effectiveness Testing In some cases, manufacturers will conduct tests that simulate real-world environments to determine how effectively the shielding can block EMI. This may involve various frequency ranges, ensuring the shield performs under different conditions.

4. Continuous Monitoring Systems More advanced factories may use automated systems to continuously monitor shielding resistance during production. This real-time data collection allows for immediate corrective actions if levels fall outside of acceptable ranges.

Conclusion

Semi-conductive shielding resistance testing is an essential process in the manufacturing of electrical cables and components. By ensuring that the shielding is functioning correctly through rigorous testing, manufacturers can enhance product reliability, ensure regulatory compliance, and maintain regulatory standards. With the rapid advancements in technology and increasing demands for higher performance materials, the methods employed in semi-conductive resistance testing will continue to evolve. Investing in robust testing protocols not only secures the quality of products but also bolsters consumer trust in the manufacturer's commitment to safety and performance. As industries move towards greater reliance on complex electronics, the importance of effective shielding will only continue to grow, making resistance testing an integral part of the manufacturing process.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy