semi-conductive test clamp factories

The Importance of Semi-Conductive Test Clamp Factories in the Electronics Industry

In today's rapidly evolving electronics industry, the demand for high-quality testing equipment is paramount. Among the crucial tools used in testing various semiconductor devices are semi-conductive test clamps. These devices play an essential role in ensuring that electronic components perform reliably and meet industry standards. This article explores the significance of semi-conductive test clamp factories and their contribution to the electronics manufacturing sector.

Understanding Semi-Conductive Test Clamps

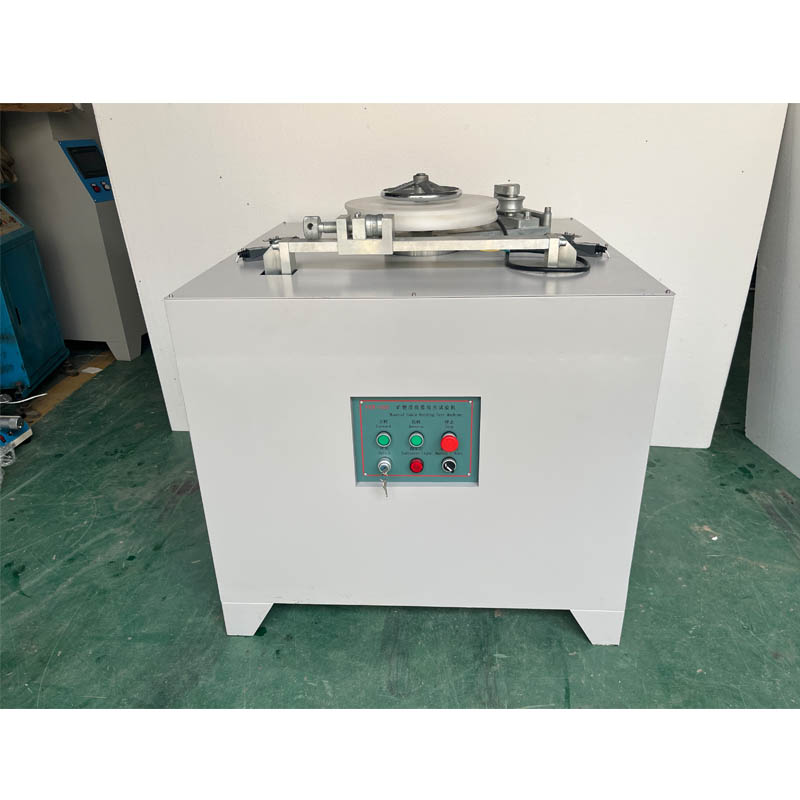

Semi-conductive test clamps are specialized instruments designed to measure electrical properties of semiconductor devices. They offer a non-destructive method of testing, which is especially important in ensuring the integrity of sensitive electronic components. These clamps typically incorporate advanced materials and technology to provide accurate readings, which are vital for manufacturers to assess the performance and quality of their products.

The Role of Factories in Production

The production of semi-conductive test clamps is a complex process that requires precision engineering and the use of cutting-edge technology. Factories specializing in the manufacture of these devices must adhere to stringent quality control standards. They integrate automation and skilled labor to ensure consistent product quality and reliability. Moreover, with advancements in manufacturing techniques, including 3D printing and rapid prototyping, these factories can develop innovative test clamp designs that meet the dynamic needs of the electronics industry.

Meeting Industry Demands

As the electronics sector continues to grow, so does the need for efficient and effective testing solutions. Semi-conductive test clamp factories play a pivotal role in fulfilling this demand. They not only produce the clamps but also engage in ongoing research and development to enhance the functionality and performance of their products. This includes improving the clamps' ability to handle a wider range of voltages and currents, ultimately leading to more robust testing capabilities.

semi-conductive test clamp factories

Furthermore, where there is rapid technological evolution, there is often a shift towards miniaturization in semiconductor technology. This places additional demands on test clamps, making the role of factories even more crucial. Factories must innovate to produce smaller, more efficient clamps without compromising accuracy or reliability. Thus, they are at the forefront of developing solutions that accommodate these industry shifts.

Quality Assurance and Certification

Quality assurance is a fundamental aspect of the operations within semi-conductive test clamp factories. Many of these factories comply with international standards, such as ISO 9001 and IPC/WHMA-A-620, which dictate rigor in manufacturing processes. Certification ensures that the clamps produced are reliable and capable of withstanding rigorous testing environments. It builds trust with consumers and manufacturers alike, allowing them to use these clamps with confidence in their testing processes.

Sustainability Efforts

In addition to focusing on quality and performance, many modern semi-conductive test clamp factories are increasingly prioritizing sustainability. The electronics industry's environmental impact has come under scrutiny, and factories are exploring eco-friendly manufacturing practices. This includes reducing waste, opting for sustainable materials, and implementing energy-efficient processes. Such efforts not only contribute to environmental conservation but also resonate with consumers who are becoming more environmentally conscious.

Conclusion

In conclusion, semi-conductive test clamp factories are integral to the electronics industry's ability to produce high-quality and reliable semiconductor devices. Through innovative production processes, adherence to quality standards, and a commitment to sustainability, these factories help ensure that electronic components perform as intended. As technology advances and new challenges arise, the role of these factories will undoubtedly become even more critical in driving the industry forward.

-

Reliable CHJ Series Spark Tester for Insulation Quality Control

NewsSep.01,2025

-

QNJ-2/3 Cable Flexibility Test Machine: Precision & Durability

NewsAug.31,2025

-

DQ-F Superfine Wire Conductor Resistance Fixture: High-Precision Testing

NewsAug.30,2025

-

ZC36 High Insulation Resistance: Reliable & Safe Performance

NewsAug.29,2025

-

CX-100 Manual Hydraulic Core Punching Machine - Efficient & Reliable

NewsAug.28,2025

-

Reliable Performance Testing with Advanced Aging Chamber Solutions

NewsAug.23,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy